Cryogenic cooling system for high-temperature superconducting motor rotors

A technology of motor rotor and cooling system, which is applied to cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of inability to use superconducting motor rotors, high system operating pressure, and high cost of helium pumps, and is conducive to installation and operation. And system reliability, low working pressure, good phase change cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

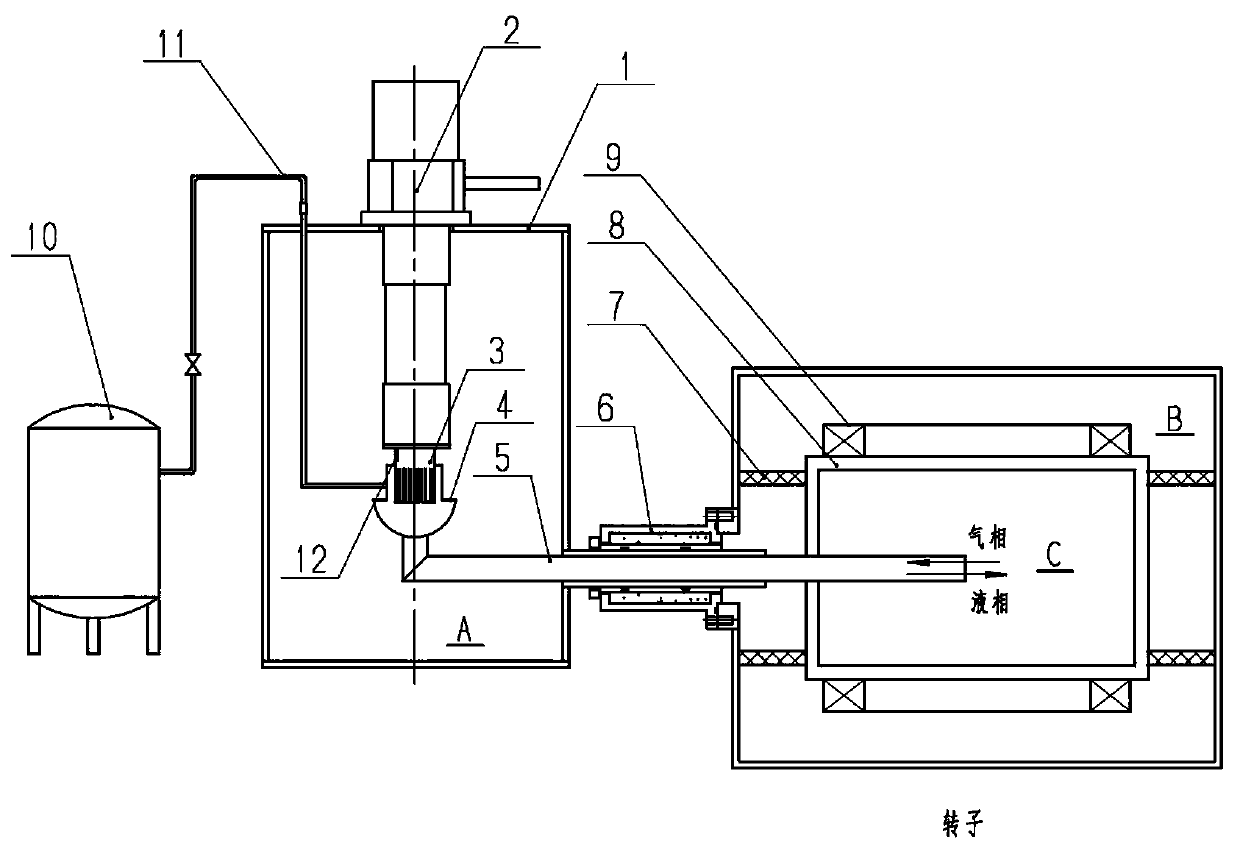

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] refer to figure 1 As shown, the present invention discloses a high-temperature superconducting motor rotor low-temperature cooling system, which includes a vacuum container 1 and a gas storage tank 10 storing neon gas. The upper end surface of the vacuum container 1 is provided with several Low-temperature refrigerator 2, the low-temperature refrigerator 2 adopts a 30K temperature zone single-stage large-capacity refrigerator, and the low-temperature refrigerator 2 can be a GM refrigerator or a Stirling refrigerator, or a single or multiple refrigerators can be used The manner in which the cryogenic refrigerators 2 operate in parallel. The cold head of the cryogenic refrigerator 2 seals and extends into the vacuum container 1, and the lower part of the cold head of the cryogenic refrigerator 2 is provided with a cold head heat exchanger 3, and the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com