A composite activated carbon filter element molded in a wet manner and a manufacturing method thereof

A composite activated carbon and wet forming technology, applied in the field of filtration, can solve the problems that the fibrous filter material cannot be assembled into a filter cartridge, and the fibrous material cannot be formed into a filter element, so as to avoid the rupture of the carbon layer of the filter element, save the design volume, The effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

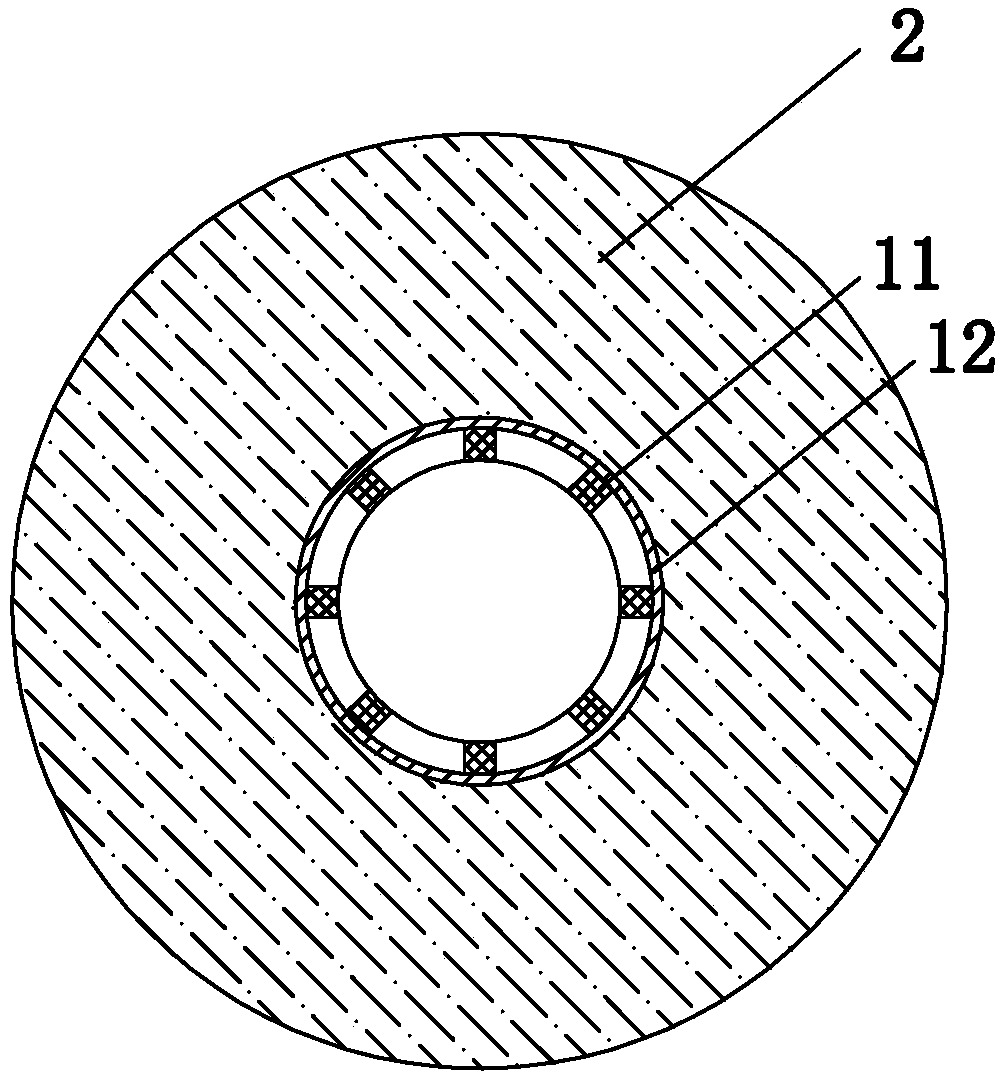

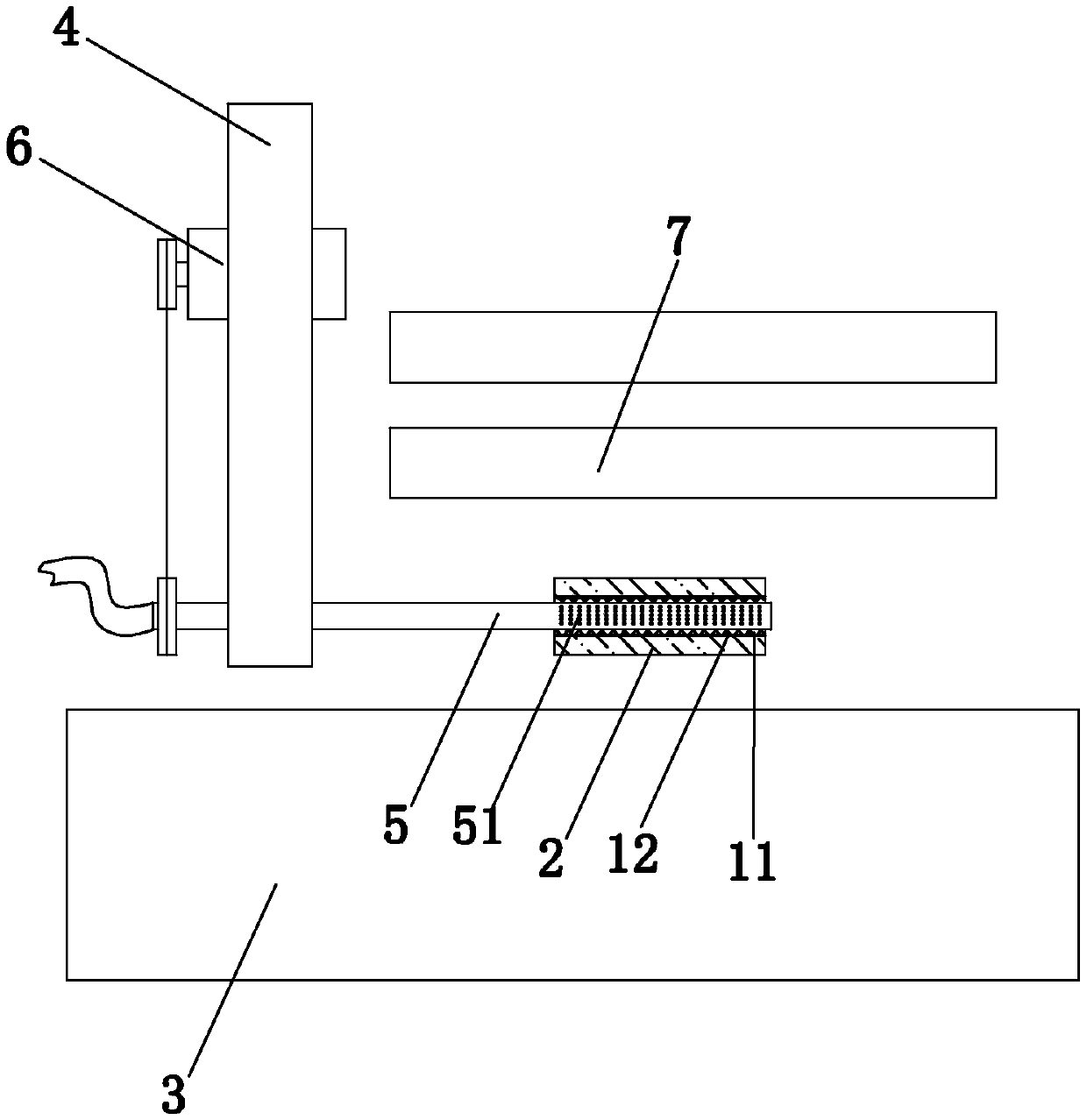

[0028] figure 1 As shown, the present embodiment provides a wet-formed composite activated carbon filter element, including a support frame tube, a filter material layer 2 sleeved outside the support frame tube, and the support frame tube includes a frame tube 11 and is sleeved on the frame tube 11 The outer non-woven fabric 12; the filter material layer 2 is made up of the material of following parts by weight: the coconut shell activated carbon particle of 75 parts by weight, the nanofiber of 15 parts by weight, the active carbon fiber of 5 parts by weight, the bonding of 5 parts by weight agent.

[0029] The adhesive is acrylic glue. The non-woven fabric is PET non-woven fabric. The skeleton tube is made of PP material. The mesh coconut shell activated carbon particles are selected from 50-100 mesh.

[0030] The above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com