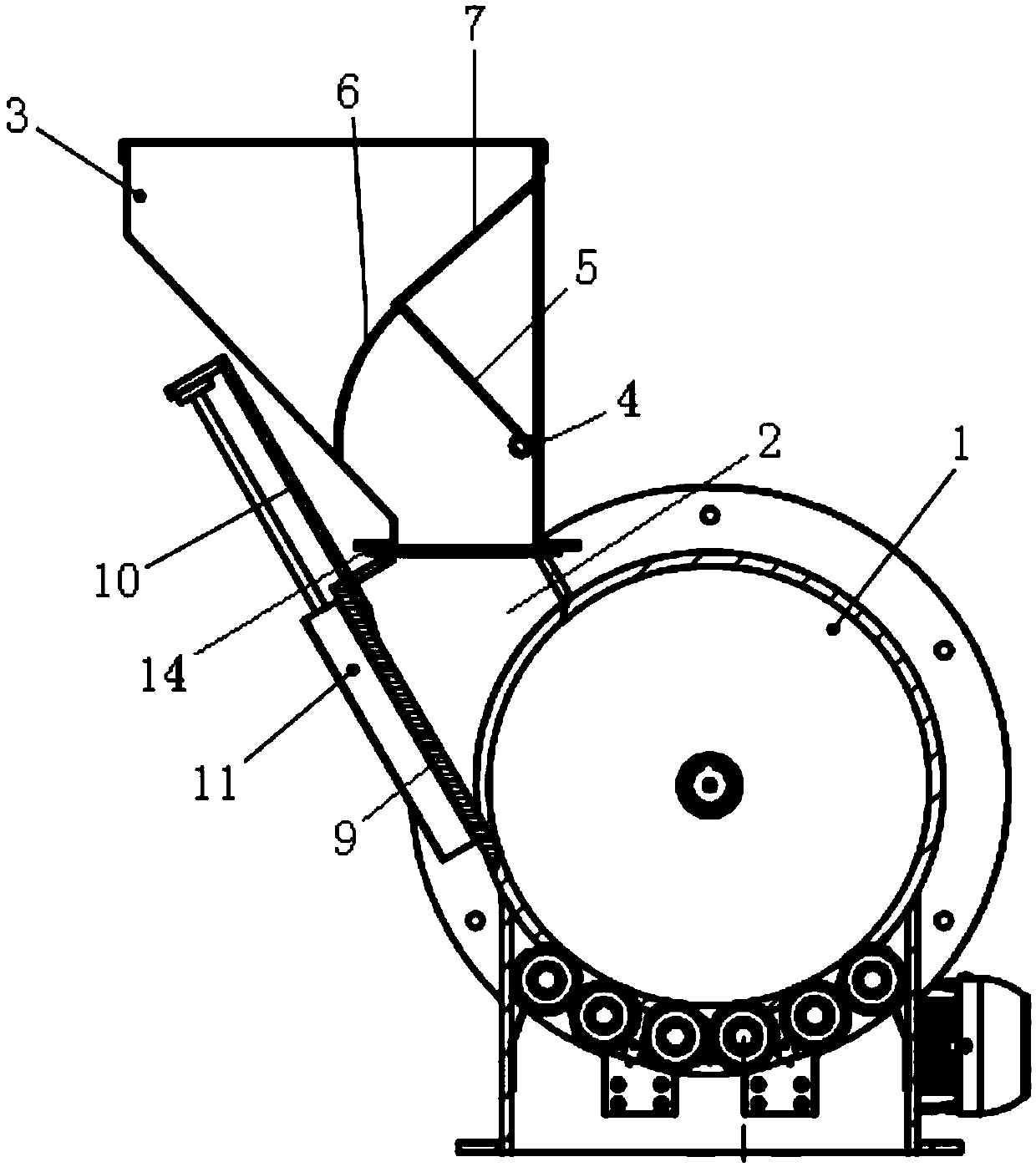

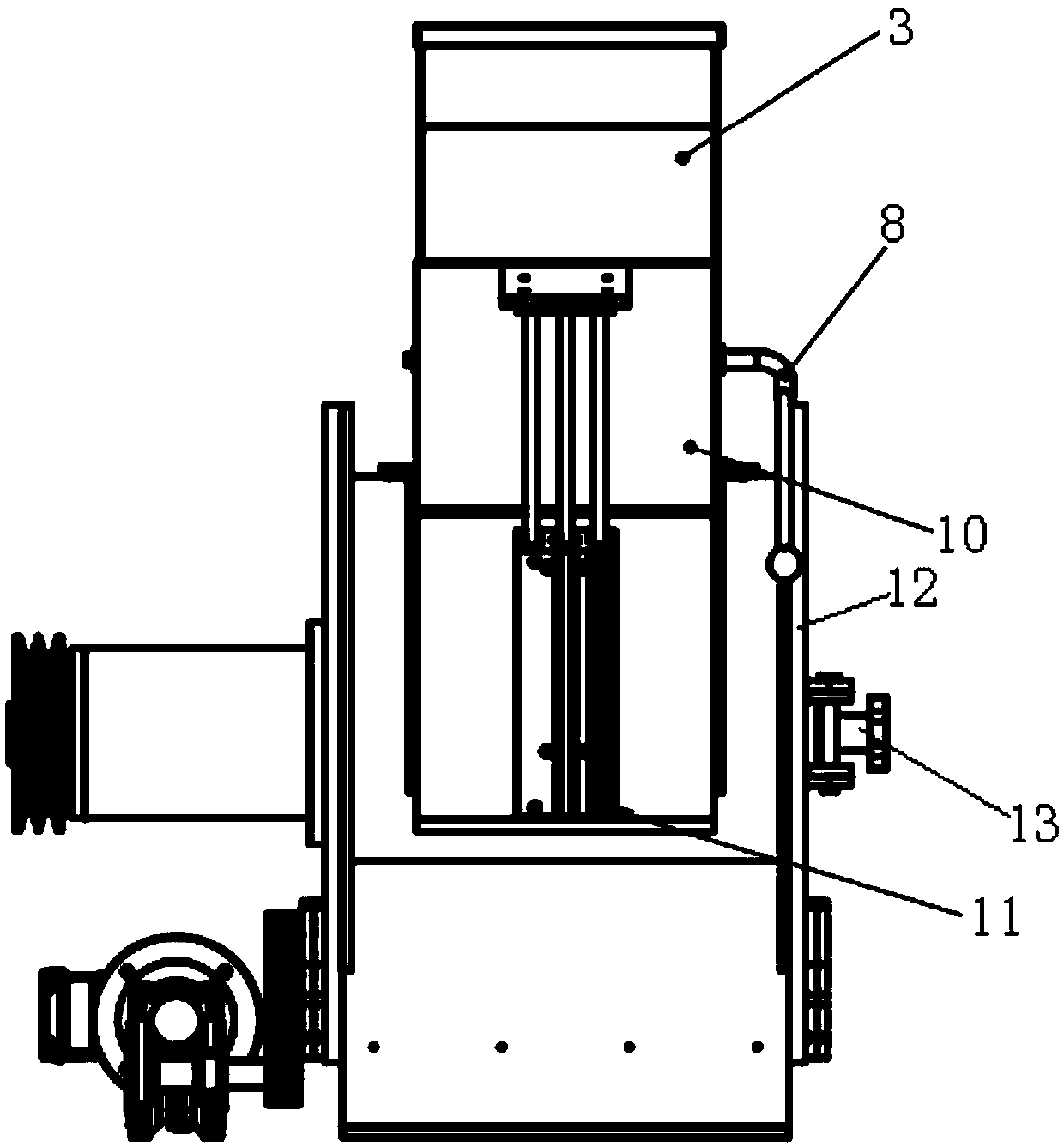

Feeding mechanism for upper-portion hopper

A feeding mechanism and hopper technology, applied in grain processing and other directions, can solve the problems of inability to finely control and affect the effect of crushed materials, and achieve the effects of easy maintenance and cleaning, reasonable design and structure, and good feeding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] When in use, the material to be crushed is fed from the top opening of the hopper, and enters along the outlet formed by the material guide plate and the inner wall of the hopper. When the material in the crushing bin is not saturated, the adjustment handle is pushed upwards, and the horizontal baffle and The baffle flips backwards to cover the space under the material guide plate, and the material flows through the hopper along the gap between the material guide plate and the inner wall of the hopper. The material slides from the hopper into the material guide groove, and slides into the crushing bin along the inclined plate.

[0026] When there is no need to enter the material or the material in the crushing bin is saturated, the horizontal baffle and the arc-shaped baffle of the pull-down adjustment handle are turned downwards, the top of the arc-shaped baffle is in contact with the inner wall of the end of the material guide plate, and the free end falls in front of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com