Intelligently controlled four-axis variable linear equal thickness vibrating screen and vibration method

An intelligent control, vibrating screen technology, applied in chemical instruments and methods, filter screens, sustainable manufacturing/processing, etc., can solve problems such as uneven feeding, reduced screening efficiency, complex working conditions, etc. The effect of installation, improving screening efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the specific embodiment in accompanying drawing:

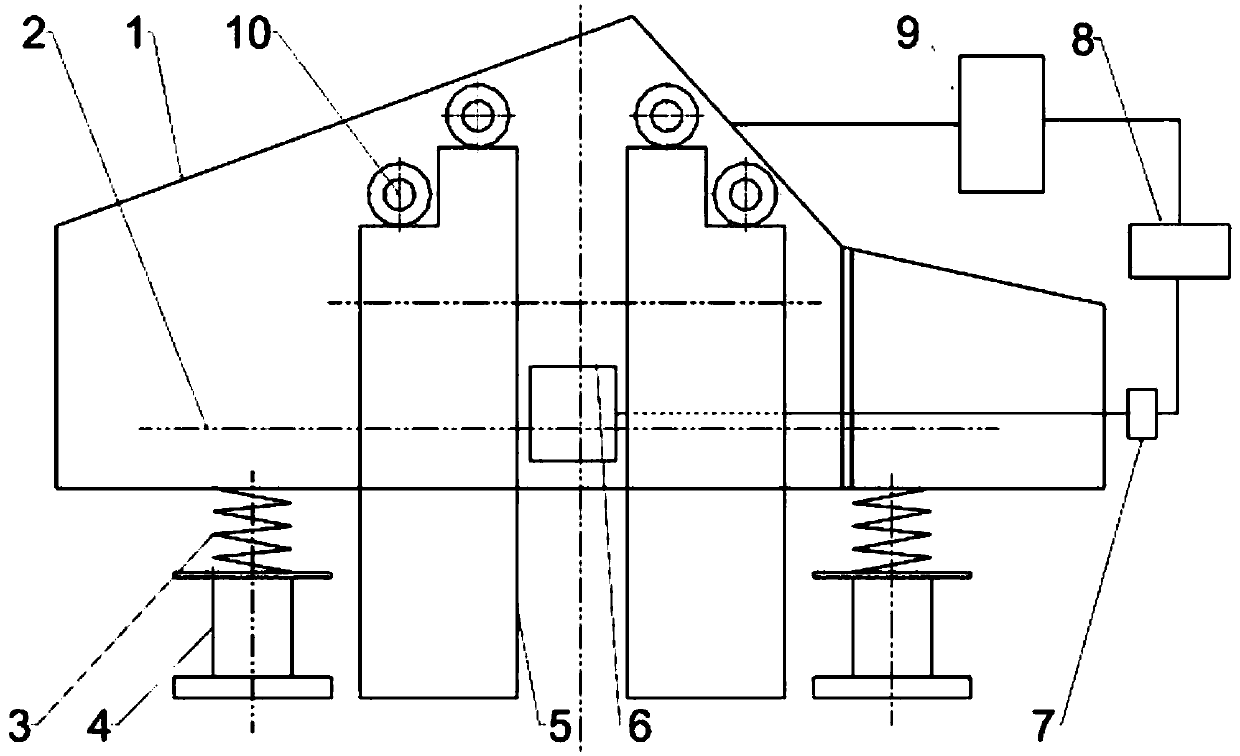

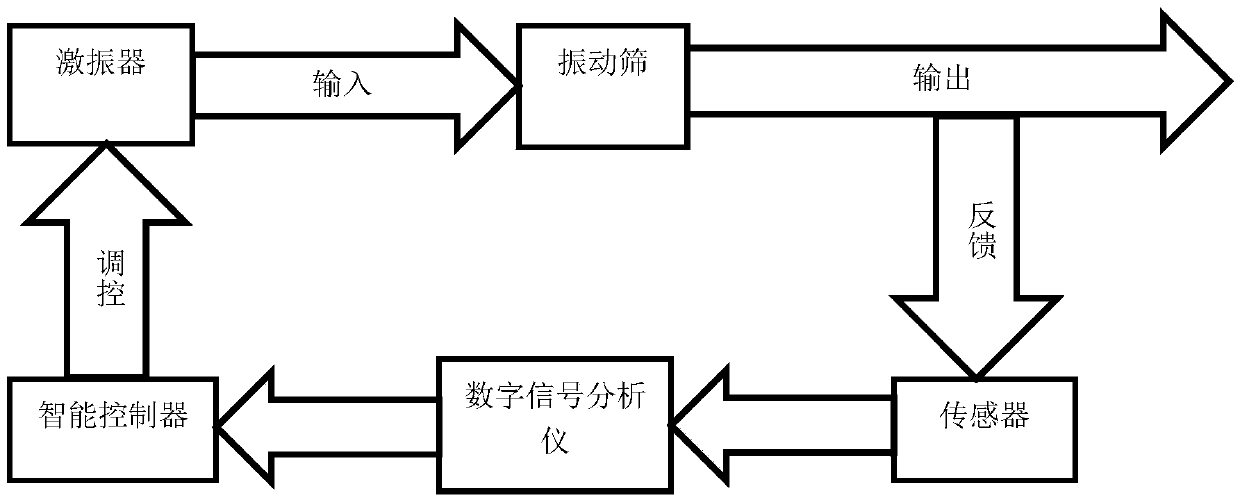

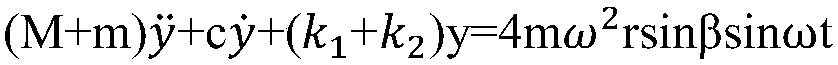

[0014] An intelligently controlled four-axis variable linear equal-thickness vibrating screen of the present invention comprises a screen box 1, a vibrating screen 2, a damping spring 3, a screen box support 4, a motor seat 5 and a vibrator 10. The vibrating screen 2 is horizontally installed at the bottom of the vibrating screen box, and the screen box is connected with the screen box support 4 through a spring 3. The sieve plate on both sides of the screen box 1 is provided with a transmission shaft, and an eccentric block is provided on the transmission shaft. The vibrator 10 composed of a variable frequency motor and a flexible coupling has four transmission shafts and the mass-diameter products of the eccentric blocks on the four transmission shafts are all equal. The vibration exciter 10 composed of frequency conversion motor, transmission s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com