Method and system for laser processing wafer

A laser processing and laser technology, used in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problem of slow response of the laser follower device and unable to keep up with the surface changes of the sample, to solve the adaptability problem and simplify the accuracy requirements , hardware design flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

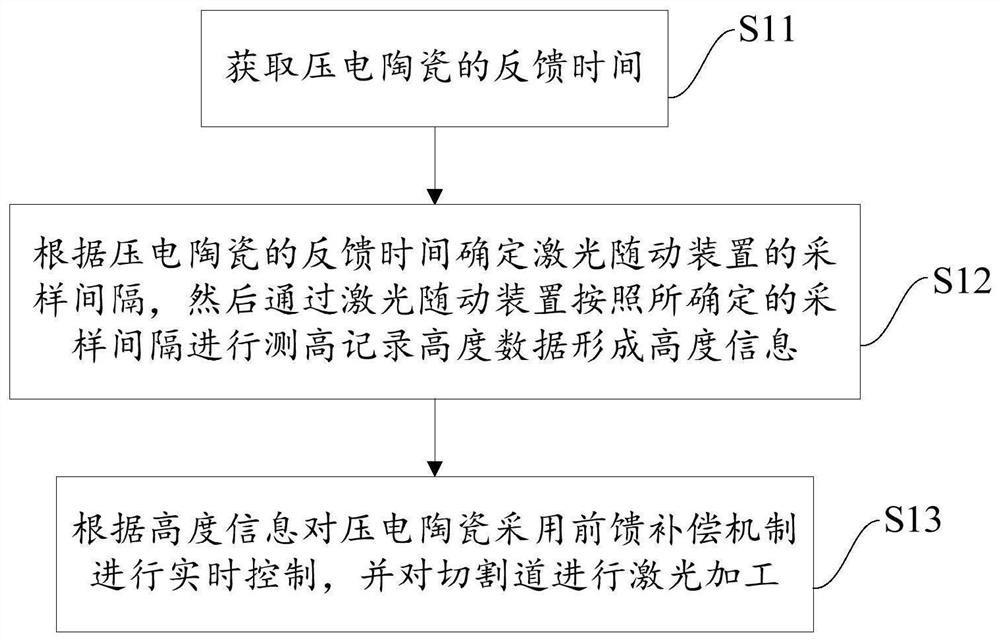

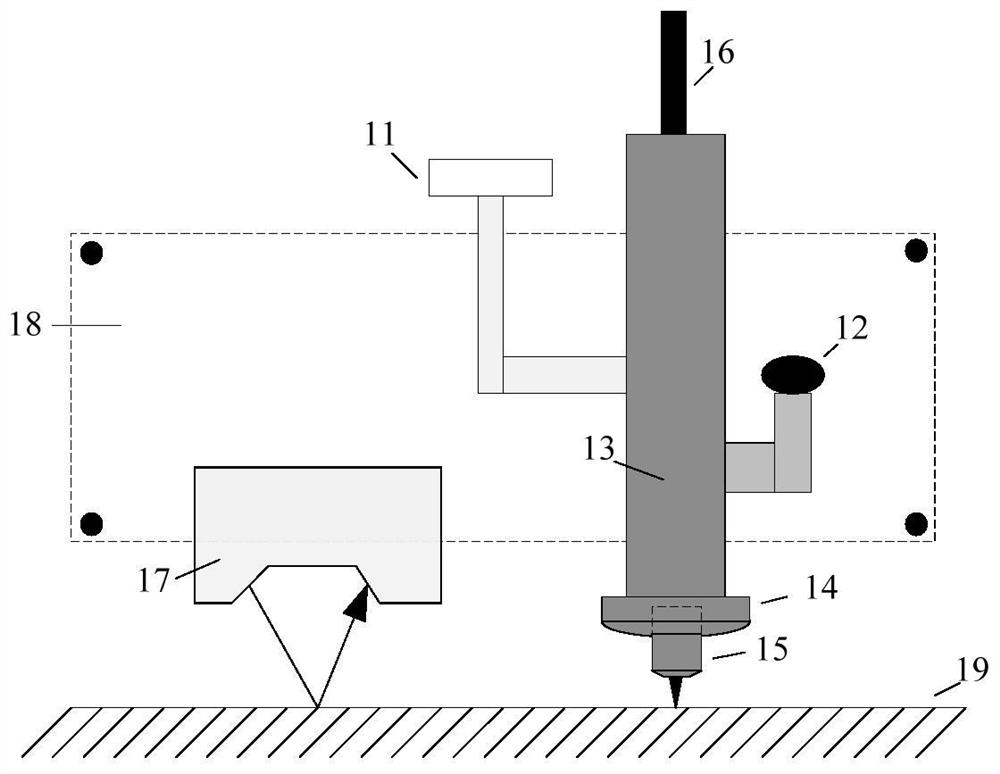

[0050] Embodiments of the present invention provide a method for laser processing wafers, such as figure 1 As shown, the method includes:

[0051] S11. Obtain the feedback time of the piezoelectric ceramic;

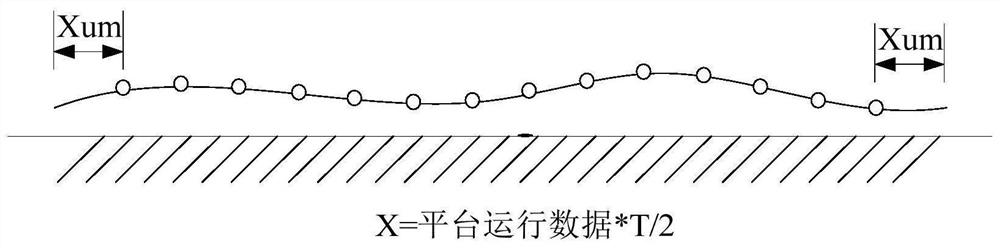

[0052] S12. Determine the sampling interval of the laser follower according to the feedback time of the piezoelectric ceramic, and then use the laser follower to measure and record height data according to the determined sampling interval to form height information;

[0053] S13. Real-time control of the piezoelectric ceramics with a feed-forward compensation mechanism according to the height information, and laser processing of the cutting lines.

[0054] The method for laser processing wafers provided by the embodiments of the present invention mainly compensates the slow response problem of piezoelectric ceramics (PZT) through the fast response capability of the controller; the specific technical solution is to match the optimal sampling time according to the feedback...

Embodiment 2

[0089] Due to the slow response of the laser servo device when the equipment is running at high speed, it cannot keep up with the change of the sample surface, and it is impossible to achieve the processing accuracy of ±1um from the change of the laser processing focus to the sample surface. Therefore, the embodiment of the present invention provides a method for laser processing wafers, such as Figure 5 As shown, the method includes:

[0090] S21. Obtain the height data of the cutting line to be processed by the laser follower;

[0091] S22. Perform data processing on the acquired height data according to the feedback time of the piezoelectric ceramics and form a positive and negative piezoelectric ceramic motion compensation table;

[0092]S23. When performing forward or reverse laser processing on the cutting line, the piezoelectric ceramics are controlled according to the forward and reverse piezoelectric ceramic motion compensation table to adopt a feedforward compensat...

Embodiment 3

[0129] Since the existing laser cutting of wafers has high requirements on the consistency of the cutting depth, the precision is at least at the micron level, but the high-speed cutting and the unevenness of the wafer surface constitute a pair of contradictory factors, and it is easy to cause the focus plane to be out of focus under the condition of high-speed movement On the wafer plane, there are breakpoints in the cutting of the wafer surface, and the frequent update of the setting value of the laser follower will also cause the oscillation error of the laser follower. Therefore, the embodiment of the present invention provides a kind of method for laser machining wafer, such as Figure 8 As shown, the method includes:

[0130] S31. Scanning the cutting line to be processed, and obtaining the height data of the cutting line by the laser follower;

[0131]S32. Fitting the height data to form a height curve of the cutting line;

[0132] S33. Determine the height setting va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com