Tank body welding robot

A technology for welding robots and tanks, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficult to realize automatic welding of circular seams and straight seams, and achieve simple and convenient lifting and handling, convenient handling, and welding process Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

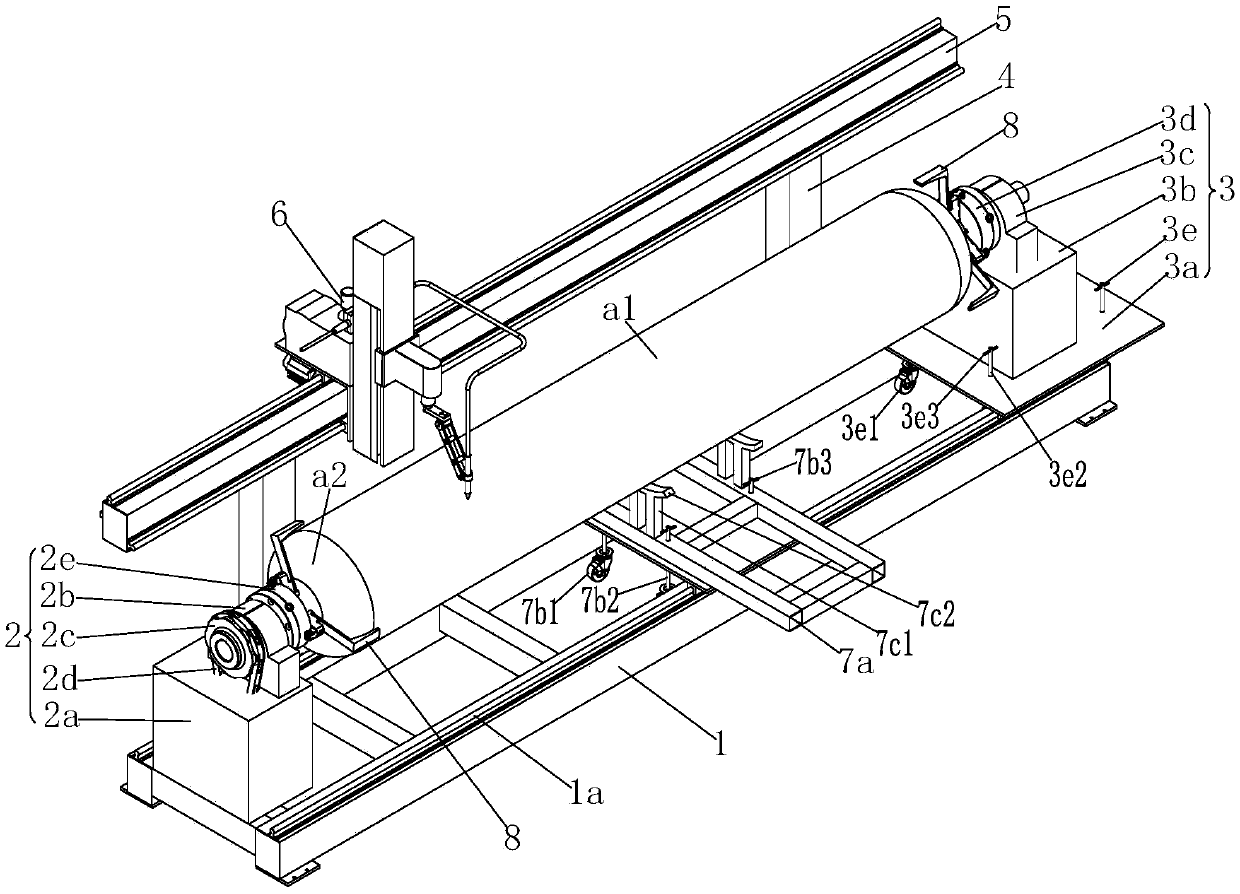

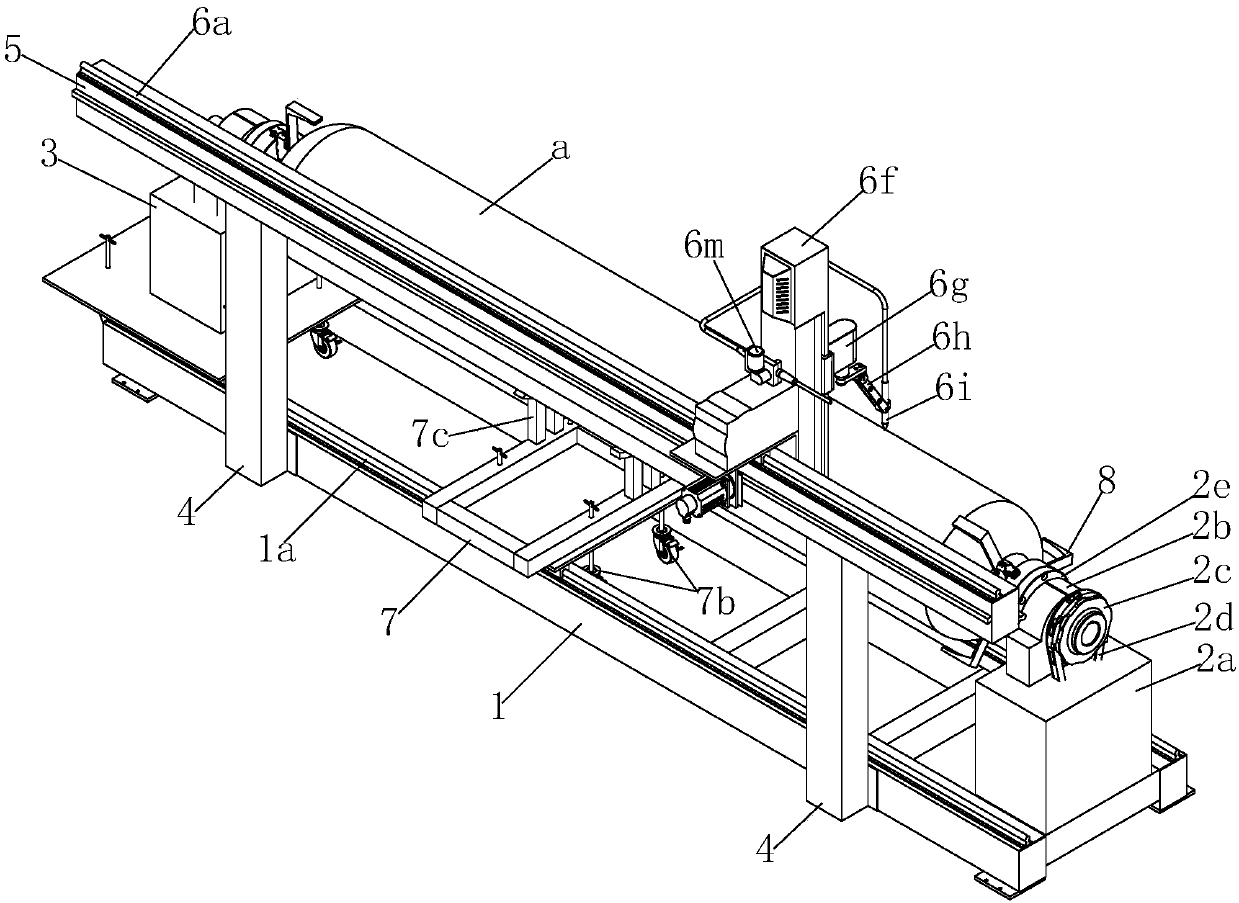

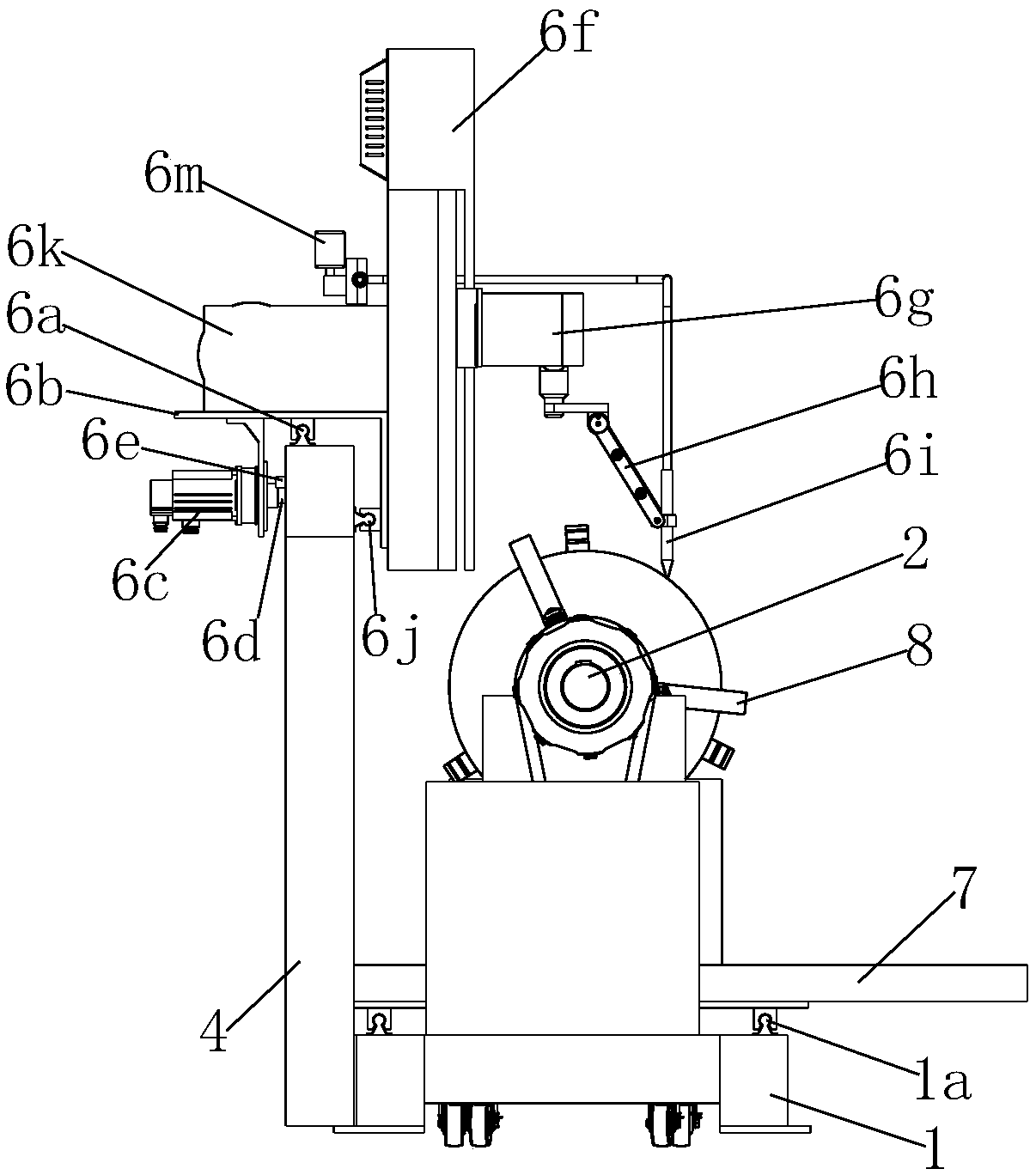

[0041] Such as figure 1 As shown, a tank body welding robot provided in this embodiment includes a base 1, and one end of the base 1 is fixedly installed with a tank body support drive assembly 2, and the tank body support drive assembly 2 includes a tank body support drive assembly fixedly installed on the The first support platform 2a on the base 1, the three-jaw chuck driving motor is installed in the first support platform 2a, the first bearing seat 2b is arranged on the top surface of the first support platform 2a, the first A first rotating shaft is installed in the bearing seat 2b, and a driving sprocket 2c is installed on one end of the first rotating shaft, and the driving sprocket 2c is connected to the output end of the three-jaw chuck driving motor through a driving chain 2d. The other end of the first rotating shaft is equipped with a first three-jaw chuck 2e; the two sides of the base 1 are respectively equipped with a base guide rail 1a, and the other end of the...

Embodiment 2

[0055] Such as figure 1 As shown, the welding method of a tank body welding robot provided in this embodiment includes the following steps:

[0056] (1) A tank body a1 is spot-welded with two tank bottoms a2 to obtain a tank body a to be welded;

[0057] (2) clamping the tank body a to be welded between the first three-jaw chuck 2e and the second three-jaw chuck 3d;

[0058] (3) Adjust the welding torch 6i to the seam position between the tank body a1 and the tank bottom a2;

[0059] (4) Rotate the first three-jaw chuck 2e to drive the tank body a to be welded to rotate together, and the welding torch 6i completes the welding between the tank body a1 and a tank bottom a2;

[0060] (5) Turn the first three-jaw chuck 2e to adjust the position of the seam on the can body a1, and adjust the position of the welding torch 6i so that the welding torch 6i is aligned with the seam on the can body a1 Patchwork;

[0061](6) The X-axis drive motor 6c drives the welding torch 6i to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com