A rotary air blowing cleaning mechanism

A cleaning mechanism and rotary air blowing technology, which is applied to metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of insufficient cleaning, waste of compressed air, long cleaning time, etc., and improve the utilization rate of machine tools , Reduce consumption, high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the present invention is not limited to the following specific examples, and all equivalent transformations made on the basis of the technical solutions of the present application fall within the protection scope of the present invention.

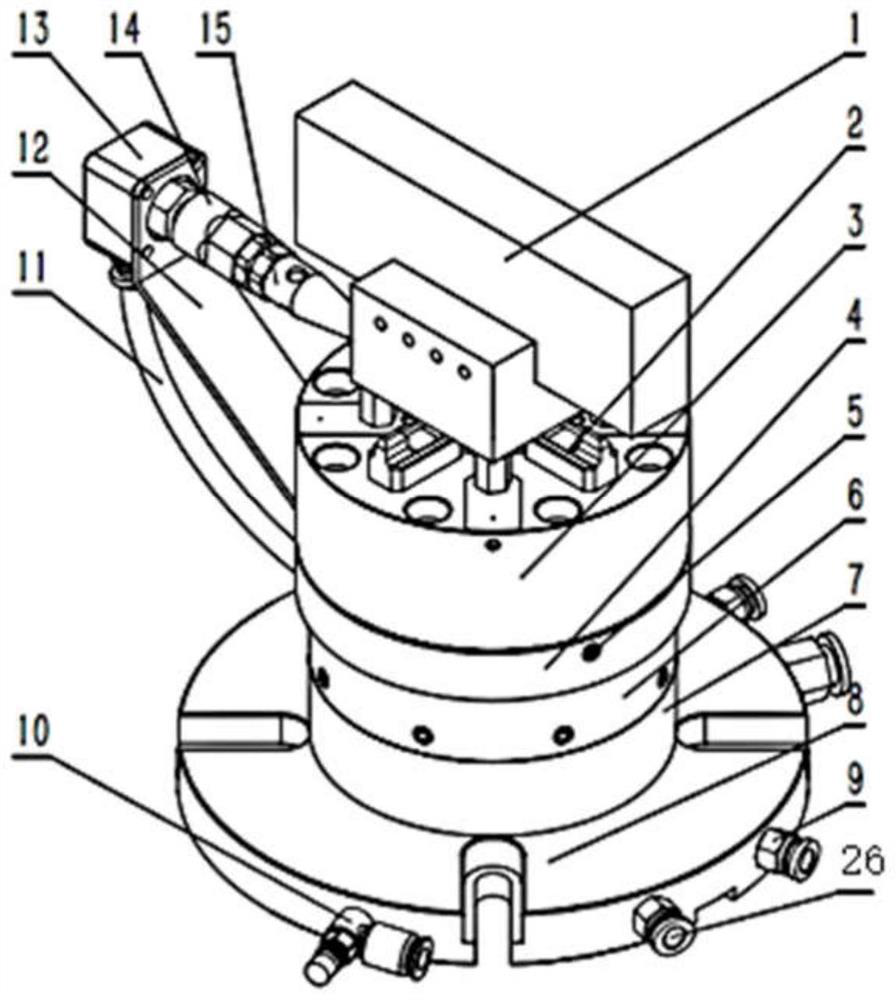

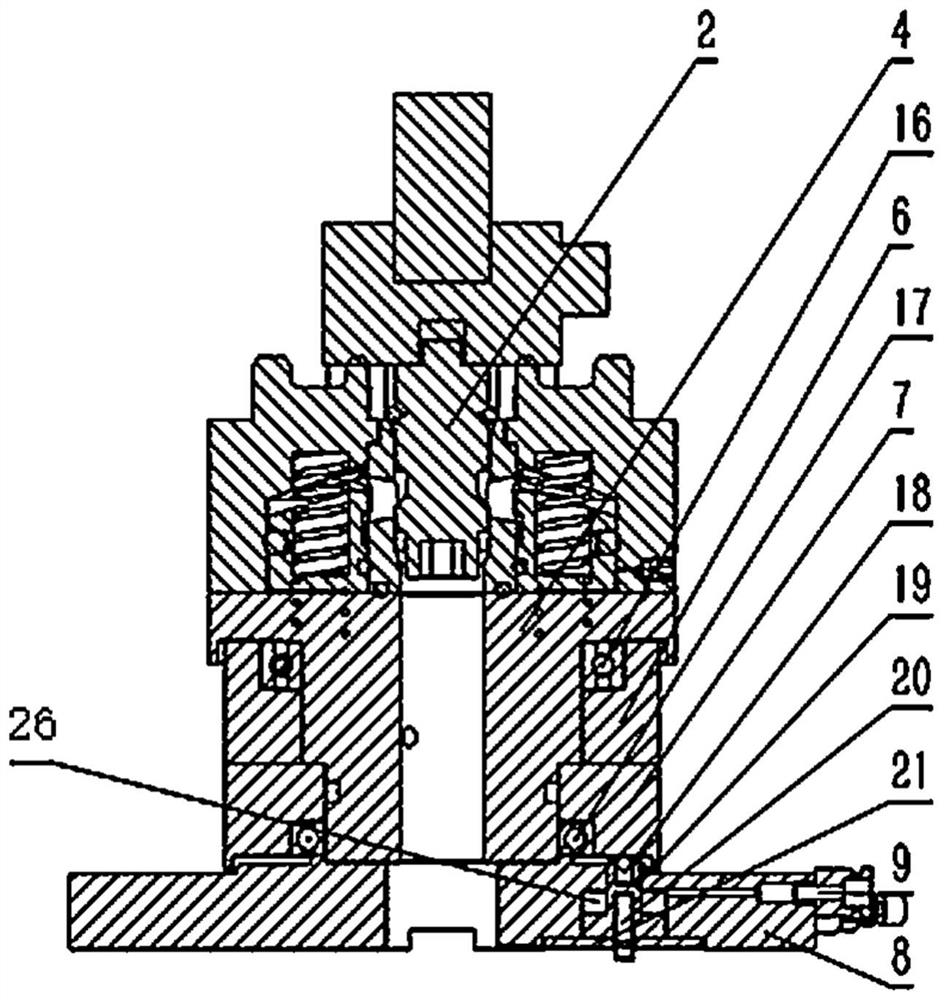

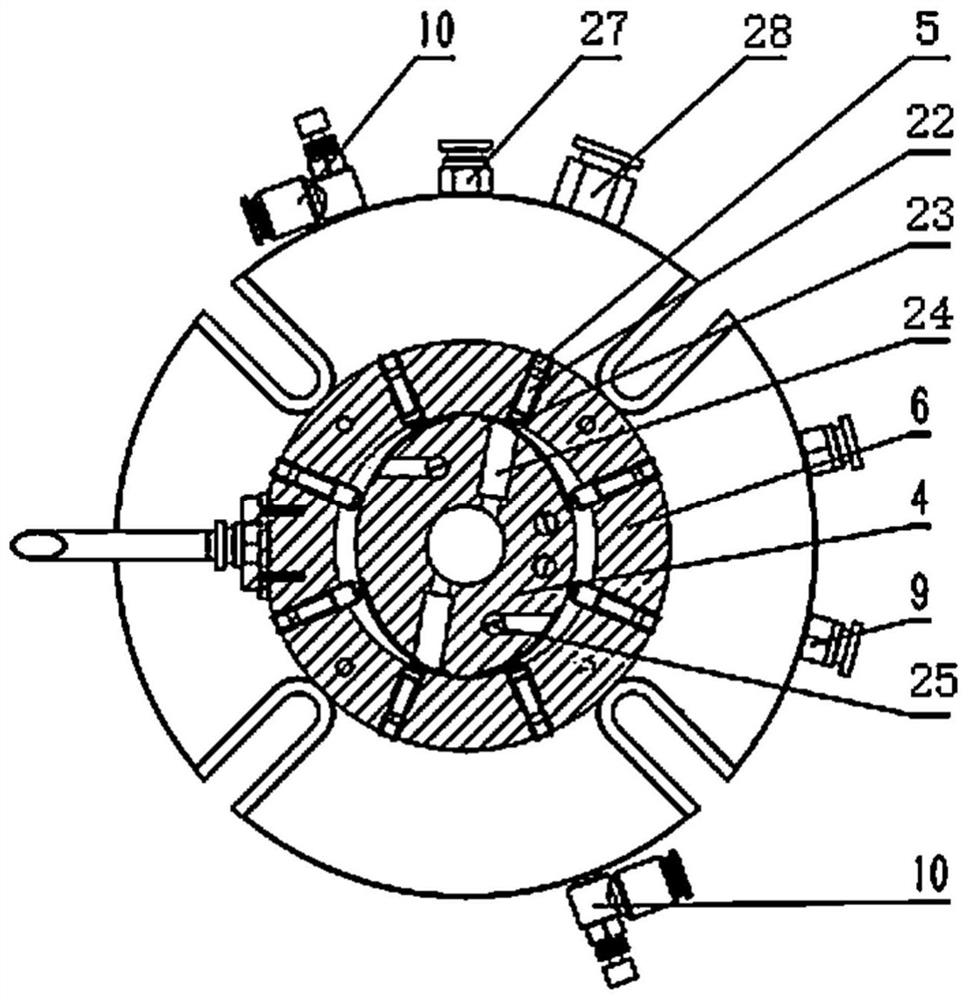

[0013] see Figure 1-3 , the present invention can realize 360° no-dead-angle cleaning for zero-point quick-change chucks, and this rotary blowing cleaning mechanism structurally includes a fixed base 8, a positioning mechanism, a rotating mechanism and a cleaning mechanism.

[0014] There are six ventilation holes arranged on the periphery of the fixed base 8, which are the first rotating air hole, the positioning air hole, the cleaning air hole, the chuck opening / closing air hole, the chuck positioning foot cleaning air hole, and the second rotating air hole. The first rotating air hole is to provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com