Differential mechanism housing surface polishing equipment

A surface polishing and differential technology, which is applied in the direction of grinding/polishing equipment, surface polishing machine tools, metal processing equipment, etc., can solve the problem of discounting the life and utilization rate of the differential housing, ineffective removal of burrs, and differential Polishing of the device shell and other issues to achieve the effect of increasing motion activity, improving polishing quality, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

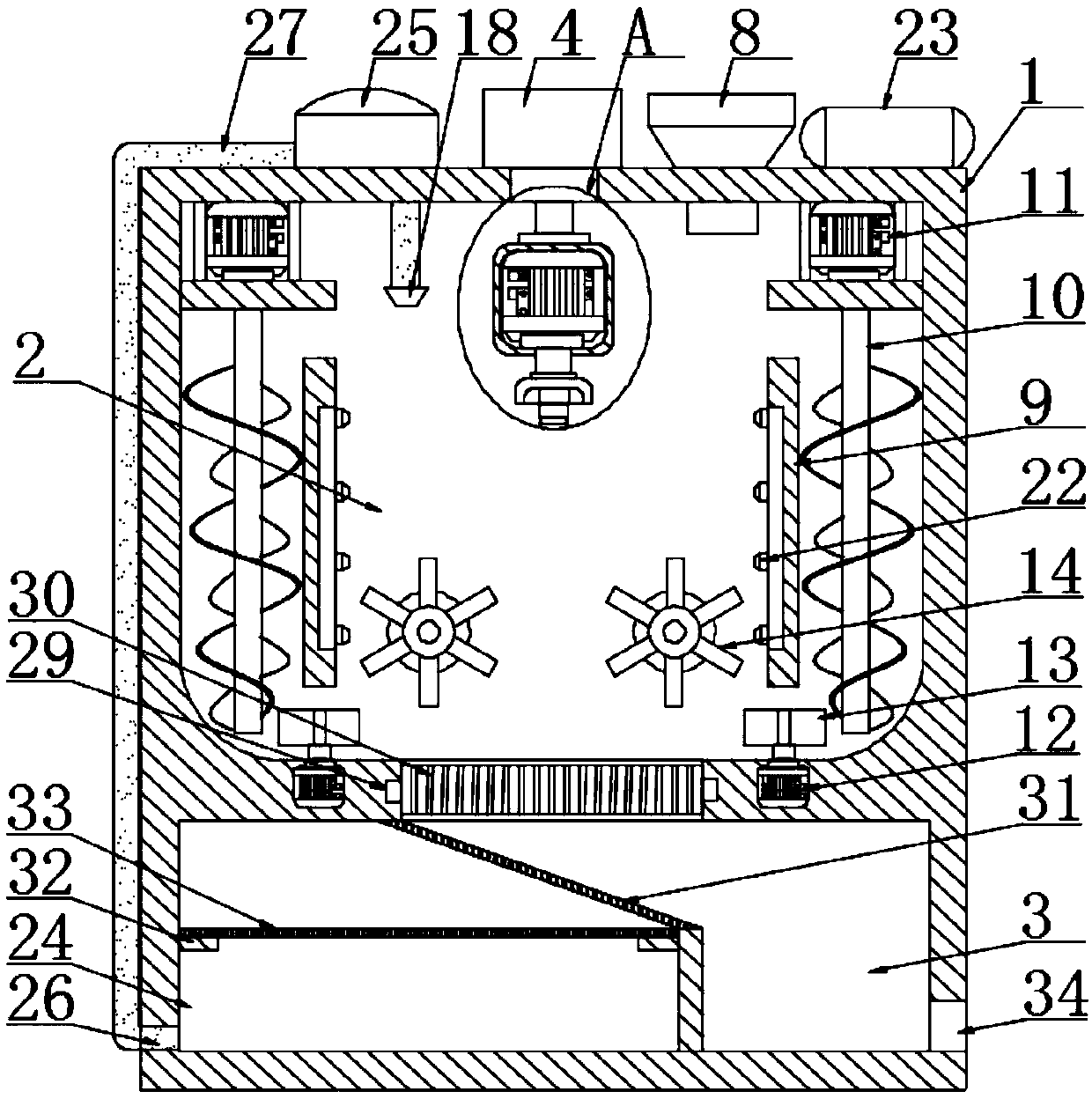

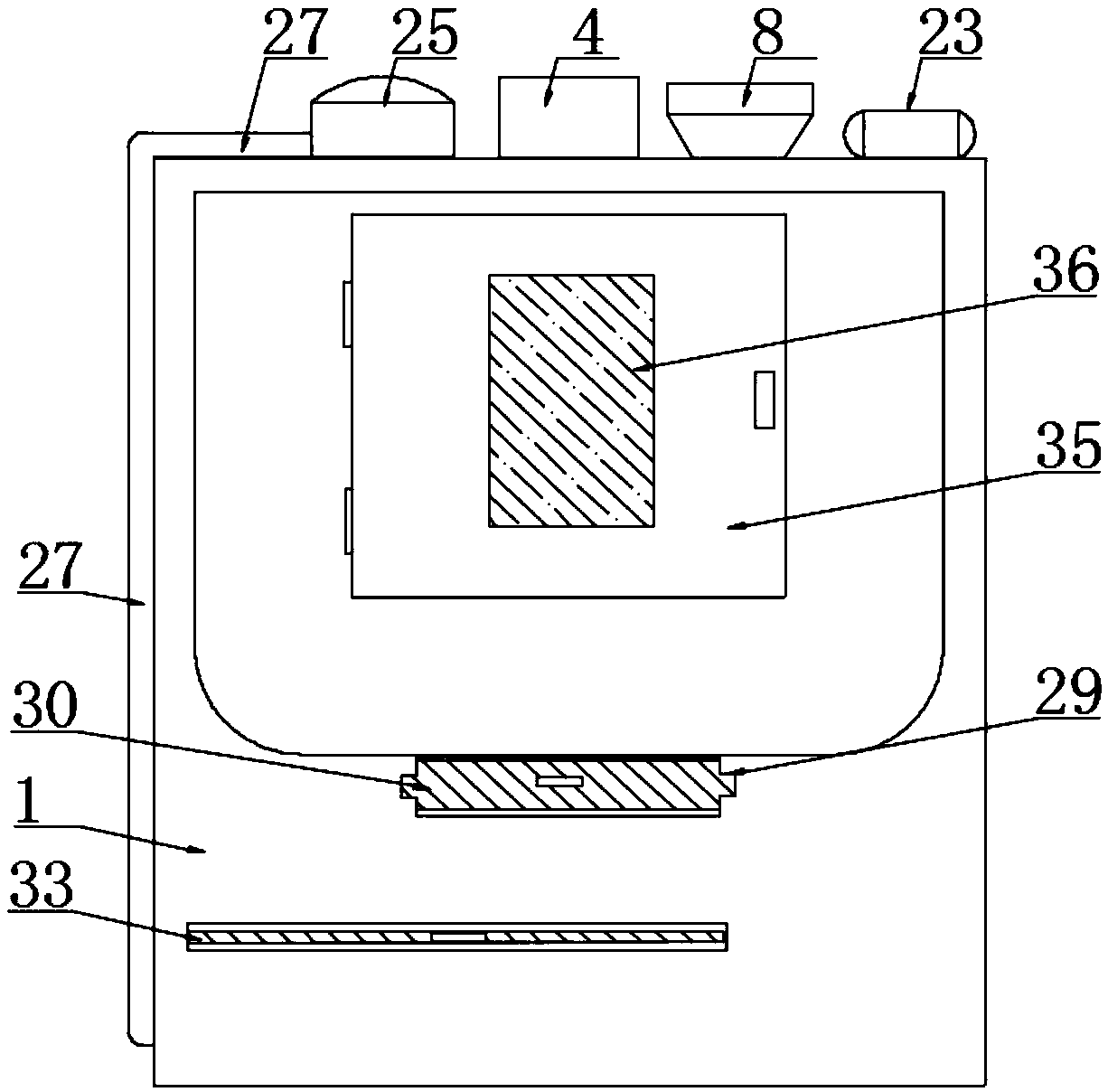

Embodiment 1

[0026] according to figure 1 and 5 The surface polishing equipment for a differential case shown includes a box body 1, a polishing chamber 2 is provided inside the box body 1, a silo 3 is provided at the bottom of the polishing chamber 2, and a silo 3 is provided at the top center of the polishing chamber 2. There is a cylinder 4, the output end of the cylinder 4 is fixedly connected with a housing 5, the inside of the housing 5 is fixedly connected with a first motor 6, the output shaft of the first motor 6 is fixedly connected with a connecting sleeve 7, and the cylinder 4 One side is provided with a feed port 8, and both sides of the polishing chamber 2 are provided with arc-shaped plates 9, and a lifting cavity is provided between the curved plate 9 and the inner wall of the box body 1, and the lifting cavity is provided with A screw rod 10, the top of the screw rod 10 is provided with a second motor 11, the output shaft of the second motor 11 is in transmission connecti...

Embodiment 2

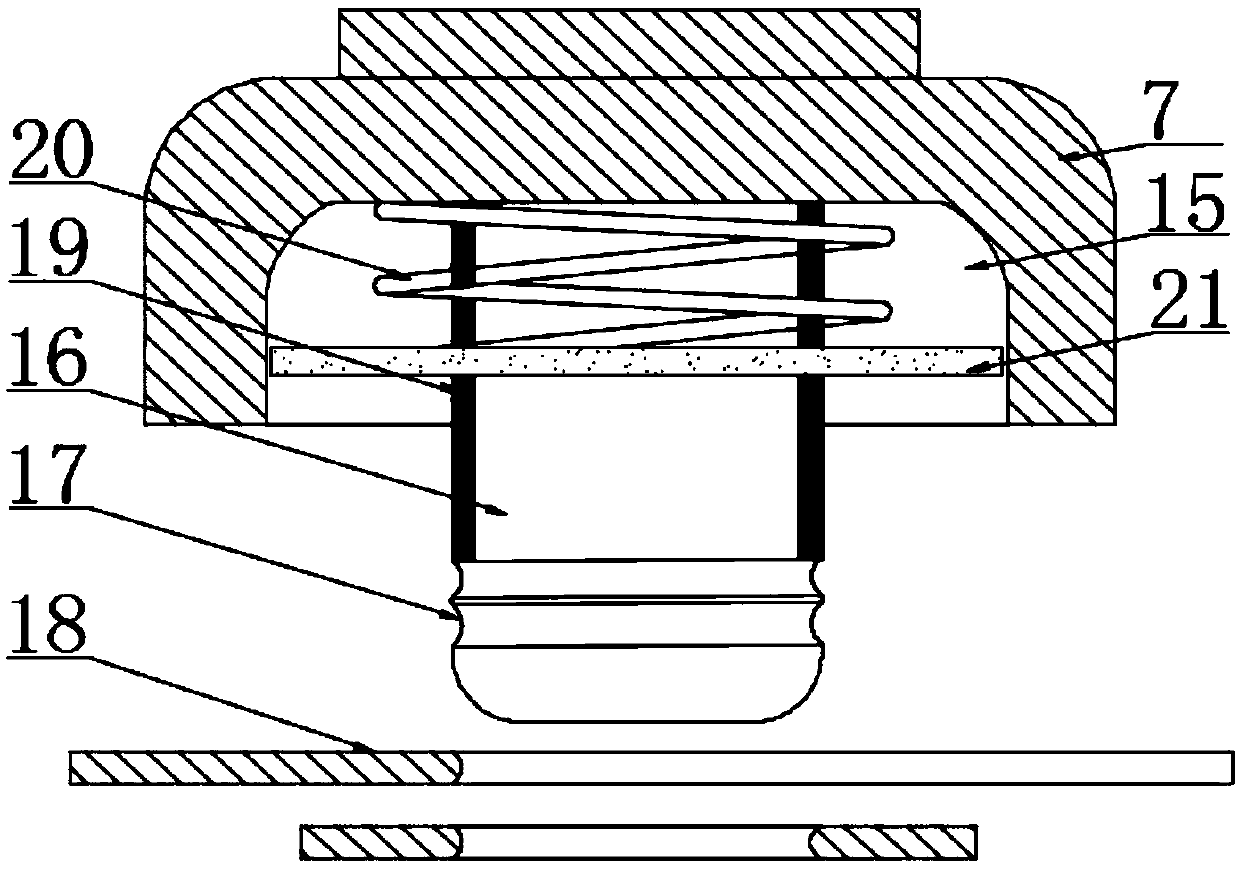

[0029] according to Figure 3-4 In the shown surface polishing equipment for a differential case, a groove 15 is provided at the bottom of the connecting sleeve 7, and an insertion rod 16 is fixedly connected to the center of the groove 15, and two bottom ends of the insertion rod 16 are provided. Parallel arc-shaped grooves 17, two arc-shaped grooves 17 are provided with vertically distributed U-shaped clamping plates 18, and the inside of the U-shaped clamping plate 18 is provided with a convex arc that matches the arc-shaped grooves 17, By inserting the inserting rod 16 into the through pipe at the top of the differential case and using two U-shaped clamping plates 18 to intersect the inside of the two arc-shaped grooves 17, the differential case can be fixedly installed, which is convenient, quick and easy to operate , which is conducive to improving the processing efficiency;

[0030] The outer side of the insertion rod 16 is provided with a buffer pad 19, the outer side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com