Crease-resistant wear-resistant fabric

A wear-resistant fabric and fabric technology, applied in the field of fabrics, can solve the problems of unsatisfactory wear-resistant effect, unsatisfactory durability, unsatisfactory wear resistance, etc., and achieve the effects of good elasticity, good wear resistance, and excellent wrinkle resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

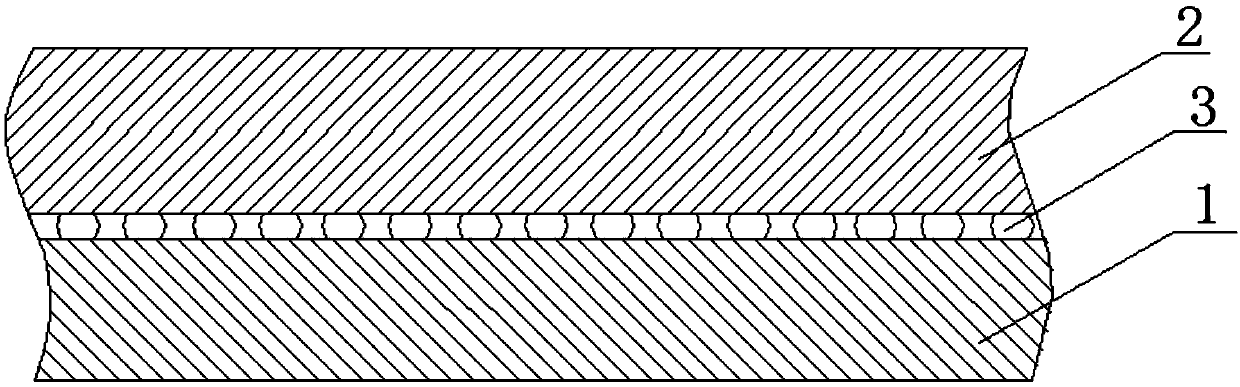

[0017] This embodiment provides a wrinkle-resistant and wear-resistant fabric, including a fabric body, the fabric body is composed of a double rib composite double-layer structure composed of a variable weft flat stitch and a tuck weave; the inner layer fabric 1 of the fabric body is composited with spandex The outer layer fabric 2 is woven by nylon composite yarn, and the inner layer fabric 1 and the outer layer fabric 2 are connected in series through the tuck structure 3. The thickness of the inner fabric 1 and the outer fabric 2 are both 0.734 mm.

[0018] The fabric body uses 10 loops as a loop. The first loop and the second loop are knitted by the high-heel stitches of the dial and the needle cylinder respectively, and a course of varying weft flat stitches are formed on the back and the front of the fabric body. Ways 3 and 4 are knitted by the low-heel needles of the dial and the needle cylinder respectively, and another course is formed on the back and front of the fabri...

Embodiment 2

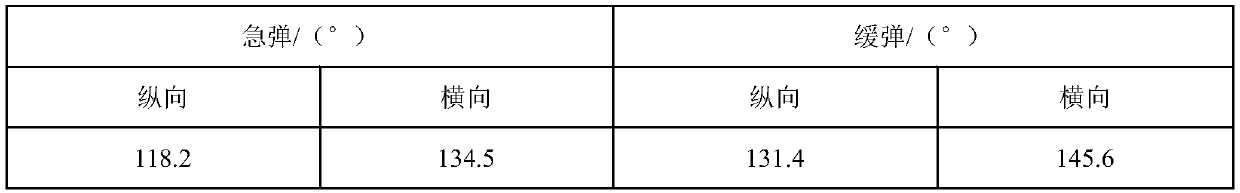

[0022] On the basis of Example 1, the outer surface of the fabric body is coated with a nano aluminum oxide wear-resistant coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com