Automatic bicycle management system and method

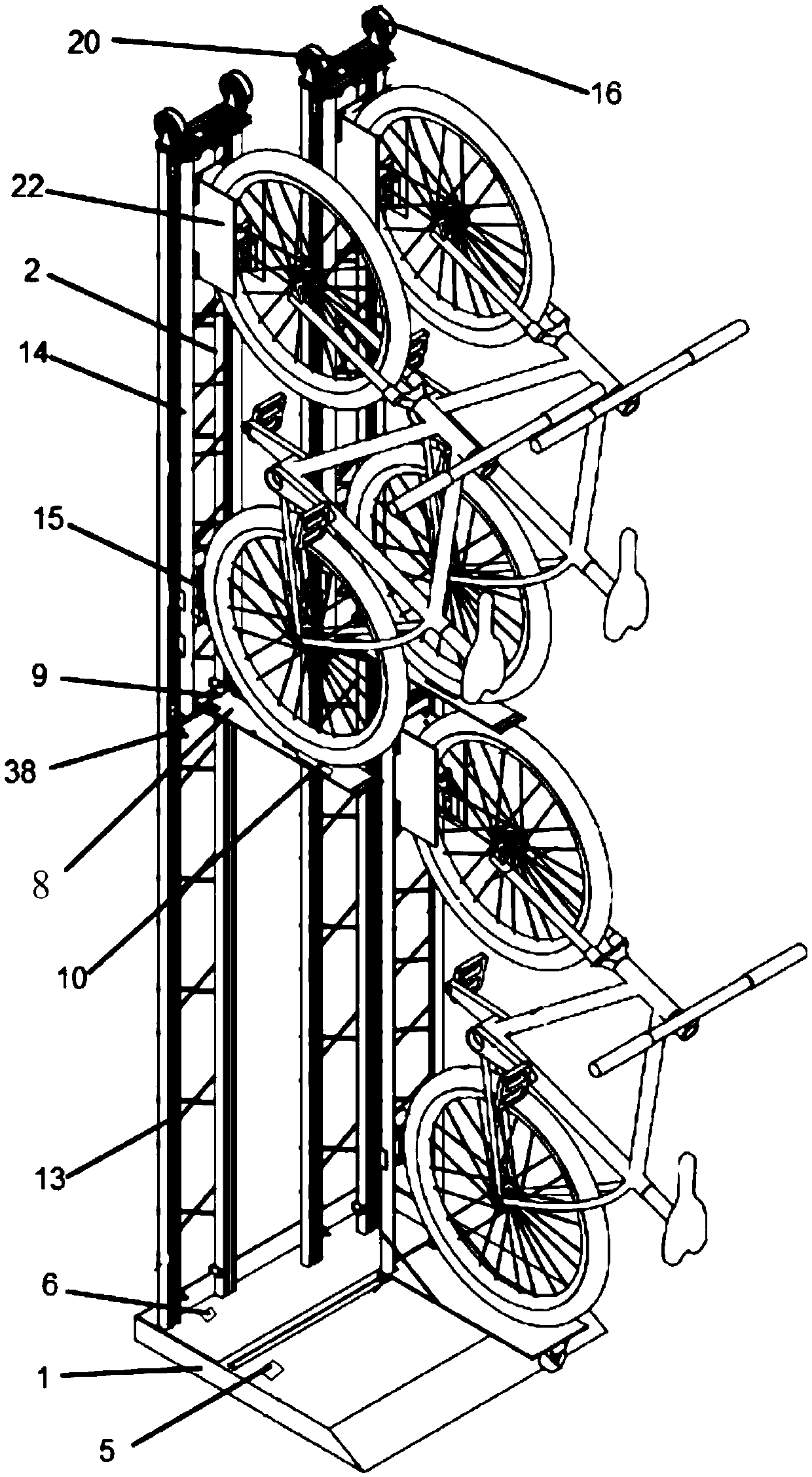

A technology for automatic management and bicycles, applied in bicycle accessories, bicycle brackets, transportation and packaging, etc., can solve the bending of the bicycle front tire body and front wheel hub, increase the single point of the clip body unit of the bicycle front wheel, increase the Problems such as the difficulty of parking or picking up the car, to achieve the effect of eliminating body sway and shaking, saving time and energy spent on parking, and stabilizing parking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

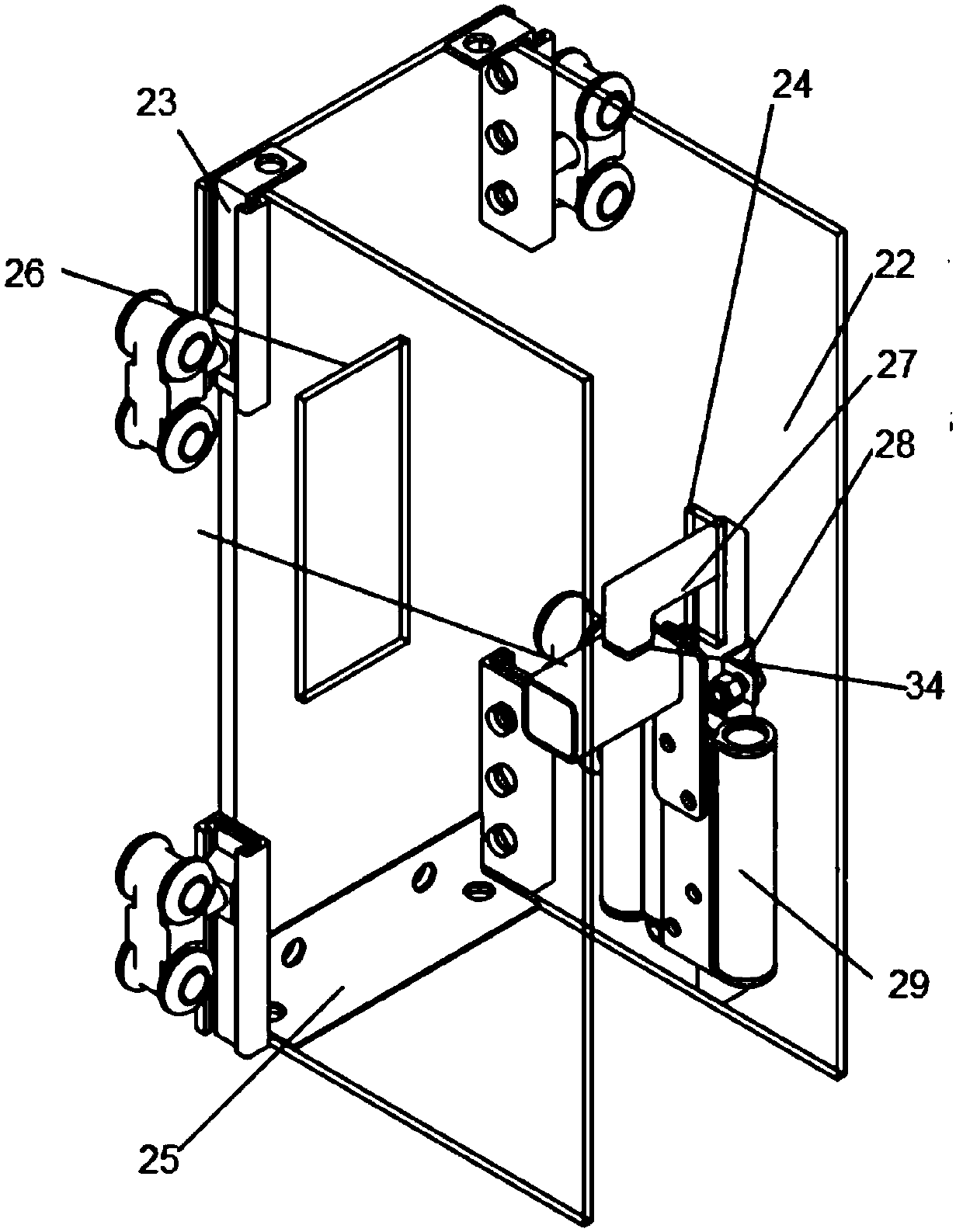

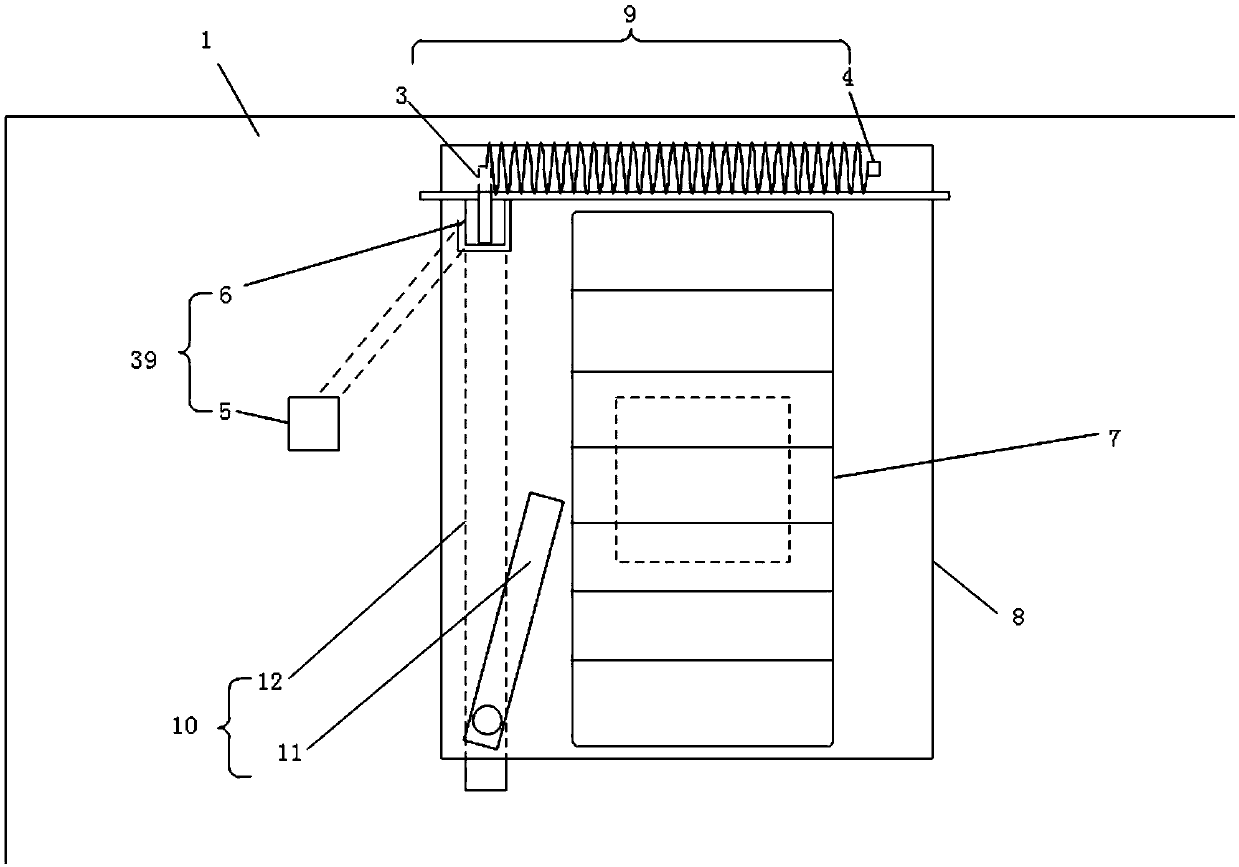

Embodiment 1

[0082] When the user prepares to park the bicycle on the lift guide rail 14, since the bottom end of the front wheel retaining frame 22 and the second end 4 of the locking rod all abut against the ground, its height is higher than the spoke pins 33, so the locking rod When it is located directly above the second through hole 34 in a non-contact manner, the spoke pins 33 are unconstrained and can move back and forth in the horizontal direction; meanwhile, the bottom plate 25 of the limit mechanism 21 limits the rotation of the lifting positioning plate 8 to the outside movement trend. Then when the user pushes the front wheel of the bicycle into the front wheel holding frame 22, the front wheel of the bicycle contacts the spoke pin 33 and continues to generate thrust to the spoke pin 33, because the spoke pin 33 is connected to the side plate 23 through the two-way hinge 29 , so the spoke pin 33 pulls the two-way hinge 29 to move inward together by compressing the return spring...

Embodiment 2

[0089] When the user is ready to take the bicycle, the user energizes the electromagnet assembly 38 by connecting the control circuit, and the electromagnet assembly 38 is in the action position for the energized state, so that the iron core located at the upper end of the lifting slideway 13 is retracted and is located at the The limit hole on the lifting guide rail 14 is disengaged from the engagement connection, and the holding of the lifting guide rail 14 at the upper end of the lifting slideway 13 is released. The user pulls the lifting positioning plate 8 to make the lifting guideway 14 move along the lifting slideway 13 under the action of gravity of the bicycle. Move downward until the vertical bottom of the lifting slideway 13. At this time, the user disconnects the control circuit, and the electromagnet assembly 38 is in a non-energized state and is in the initial position. The bit holes are snapped together, and the lifting guide rail 14 is limited at the vertical bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com