Automatic clamping device and method for diode lead

A diode and lead technology is applied in the field of diode lead automatic clamping devices, which can solve the problems of low work efficiency and high labor intensity, and achieve the effects of convenient operation, reduced labor intensity and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

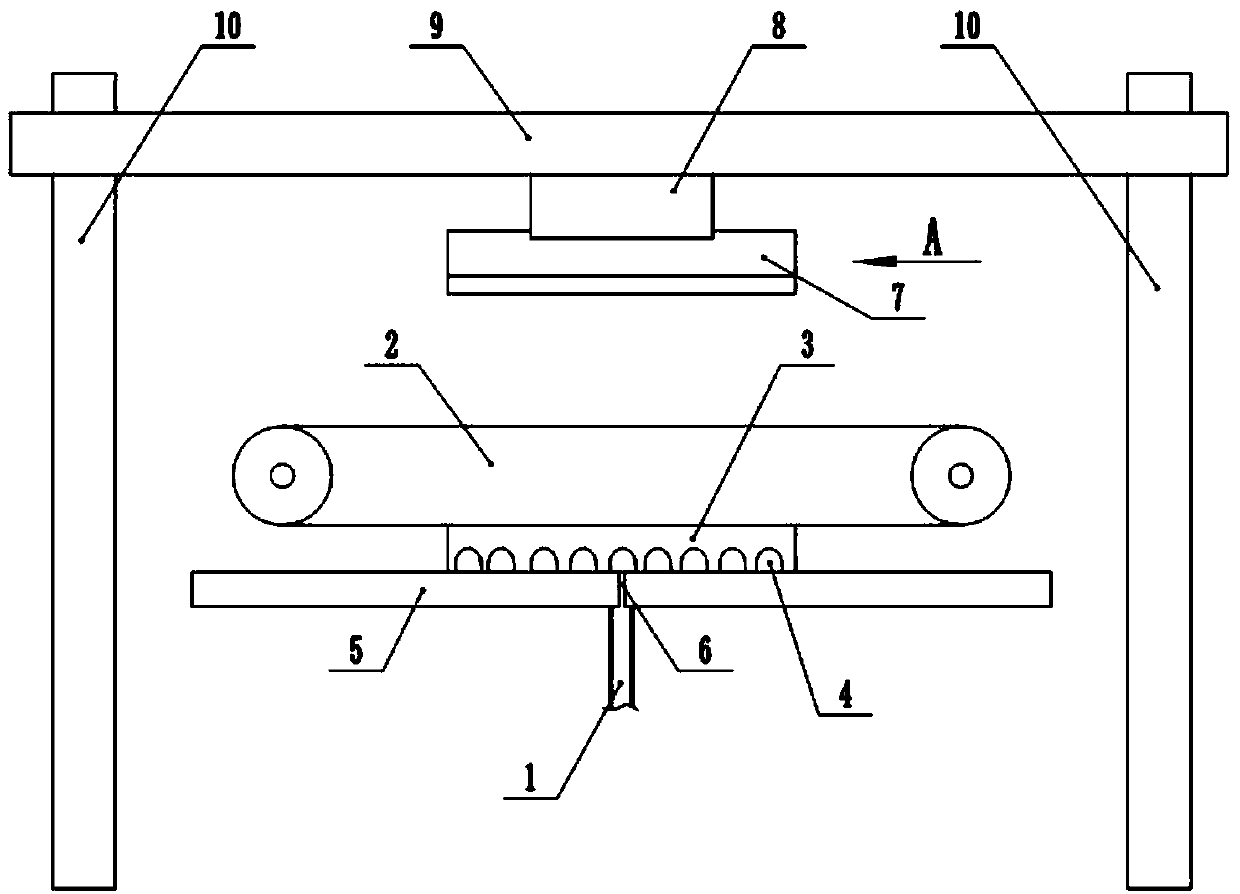

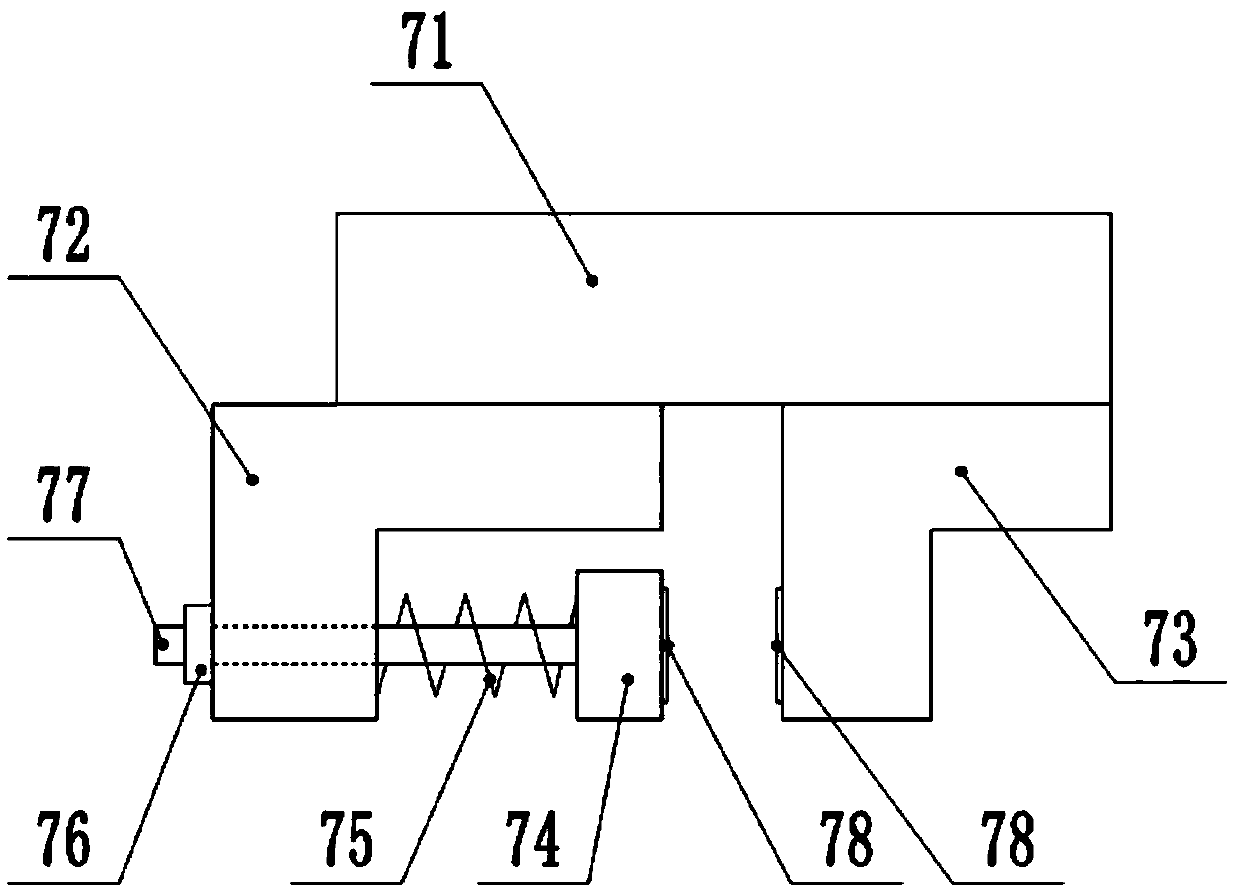

[0020] see figure 1 , according to the present invention, a diode lead automatic clamping device, including a vibrating feeder, feed channel 1, bar-shaped straight plate 5, diode stacking plate 3, circulation conveying mechanism 2, diode pick-up clip 7 and three-dimensional moving mechanism.

[0021] The vibrating feeder is a commonly used device in the field of diode production. Its function is to arrange the diodes in such a way that the leads face upward and the base is downward after vibration, and output them sequentially from the discharge channel. The discharge channel of the vibrating feeder is communicated with the feed channel 1, so that the diode can be input into the feed channel 1 with the lead wire facing up and the base down.

[0022] The strip-shaped straight plate 5 has a transition channel 6 communicating with the feed channel 1 . Preferably,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com