Online type multi-layer circuit board temporary storage device

A technology of multi-layer lines and buffering equipment, which is applied in the direction of conveyor control devices, conveyor objects, object stacking, etc., can solve the problems of small buffer capacity, poor adaptability and versatility, etc., to improve production efficiency and adaptability And strong versatility, the effect of increasing the cache capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

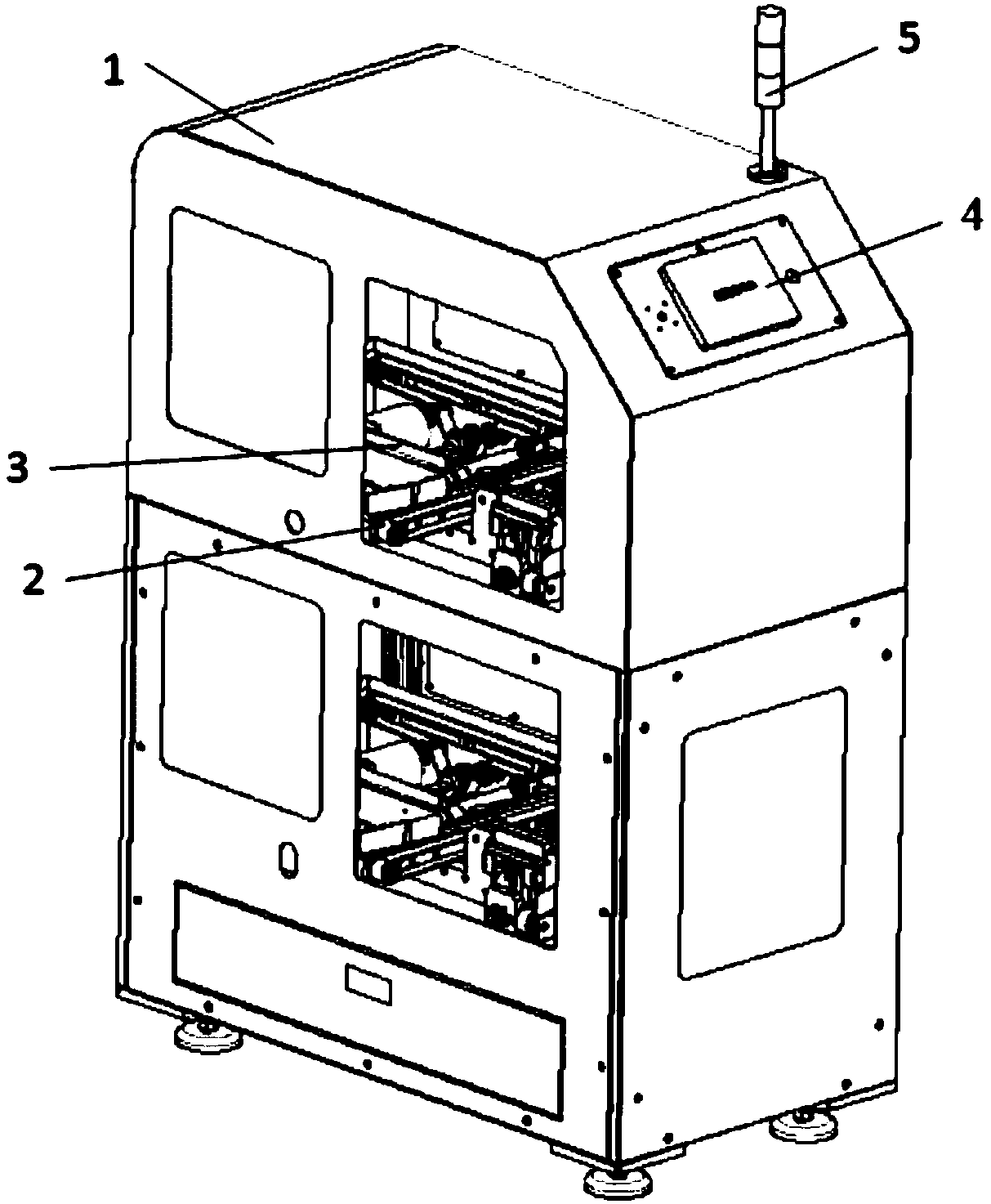

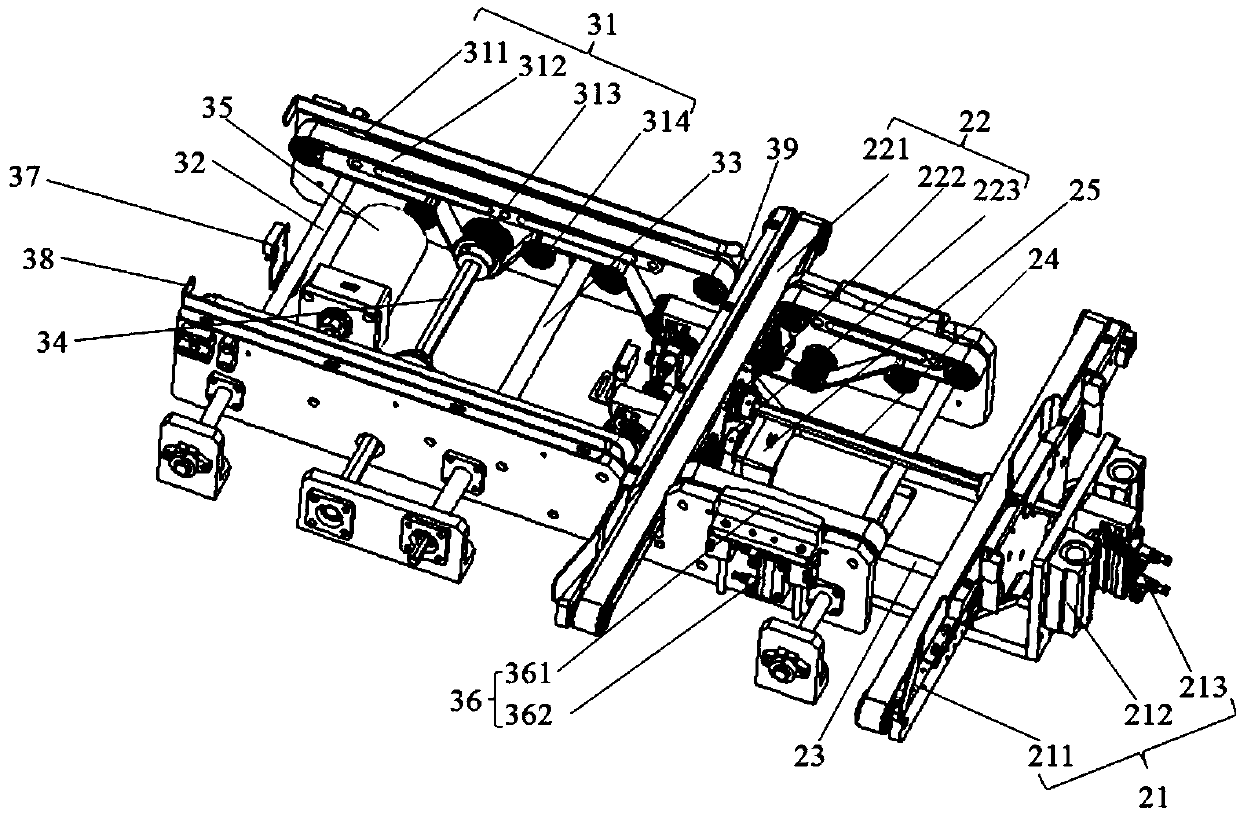

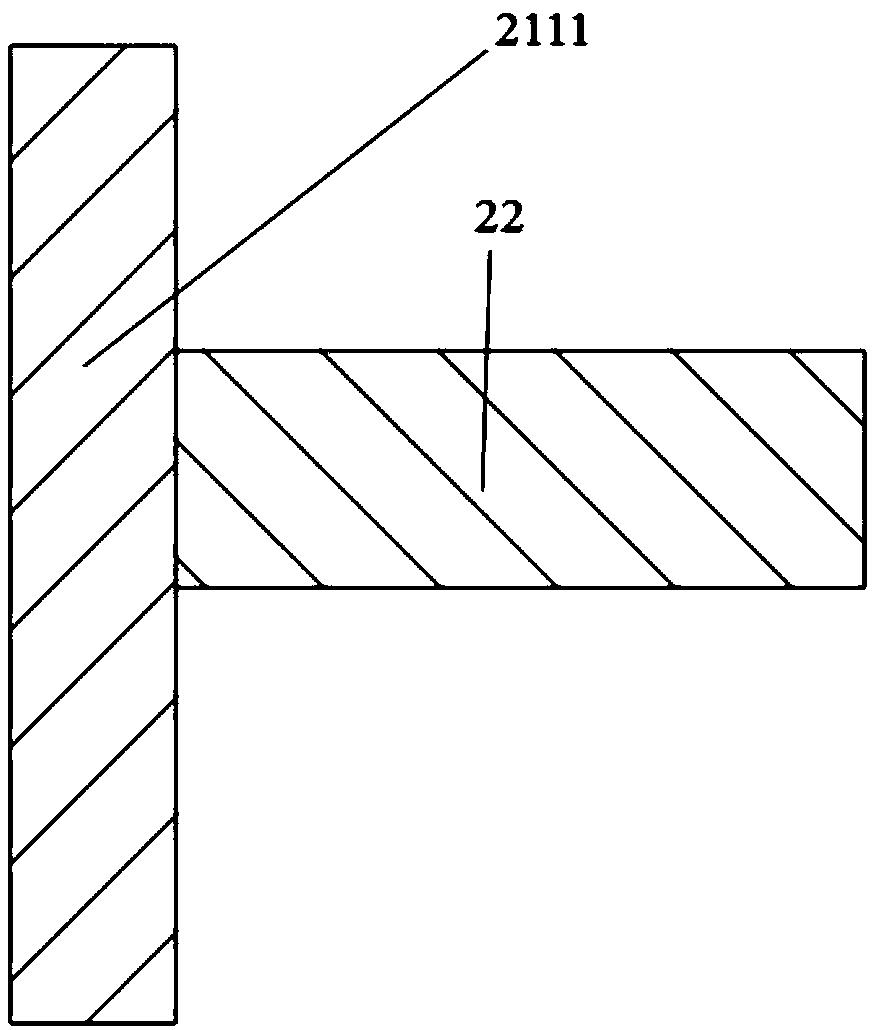

[0023] see figure 1 , the present invention provides an online multi-layer circuit board caching device, comprising: a frame 1 and a plurality of independent sets of track mechanisms arranged inside the frame 1, and each set of track mechanisms includes: a connecting track Mechanism 2, and cache track mechanism 3, the track running direction of described connecting track mechanism 2 is perpendicular to the track running direction of described buffer track mechanism 3, and the two ends of described connecting track mechanism 2 can all be able to push and receive the trigger The track is docked, and the track running direction of the connecting track mechanism 2 is consistent with the track running direction of the push-retract trigger track. The connecting track mechanism 2 can be lifted up and down, so as to realize the transportation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com