A kind of amorphous carbon/nano-micron network film and preparation method thereof

A technology of amorphous carbon and nano-film, applied in the field of nano-materials, can solve problems such as affecting application, poor stability, and short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] Specifically, an amorphous carbon / nano - Preparation micron film network, comprising the steps of:

[0052] 1) on the substrate 1 prepared nano - network 2 microns, and put into a reaction chamber 11;

[0053] 2) the introduction of the carbon source 3, the growth of amorphous carbon on the substrate 1 to form the amorphous carbon / nano - micron network films.

[0054] More specifically, it is also provided for preparing amorphous carbon / admittance of a "transfer method" - micron film network, comprising the steps of:

[0055] 1) providing a first substrate, prepared on the first substrate satisfied - network microns, and into the cavity;

[0056] 2) providing a container having contained a carbon source, was prepared and placed in a sodium - a first substrate upstream network micron film; completely discharged air in the reaction chamber, under a protective reducing gas for the preparation of a nano - micron Network heating the film of the first substrate;

[0057] 3)...

Embodiment 1

[0091] Step 1: A high purity copper for later after electrochemical polishing, washed with deionized water remaining on the high-purity copper electrolytic solution, and washed 2-3 times in acetone, alcohol, deionized water, each 10 minutes, blown dry with nitrogen foil.

[0092] Step 2: The self-supporting carbon nanotube network film 2 spreads prepared by CVD on the first substrate 1, about 10nm film thickness of the carbon nanotube network embodiment of the present embodiment, a pore size of between 20nm-1000nm.

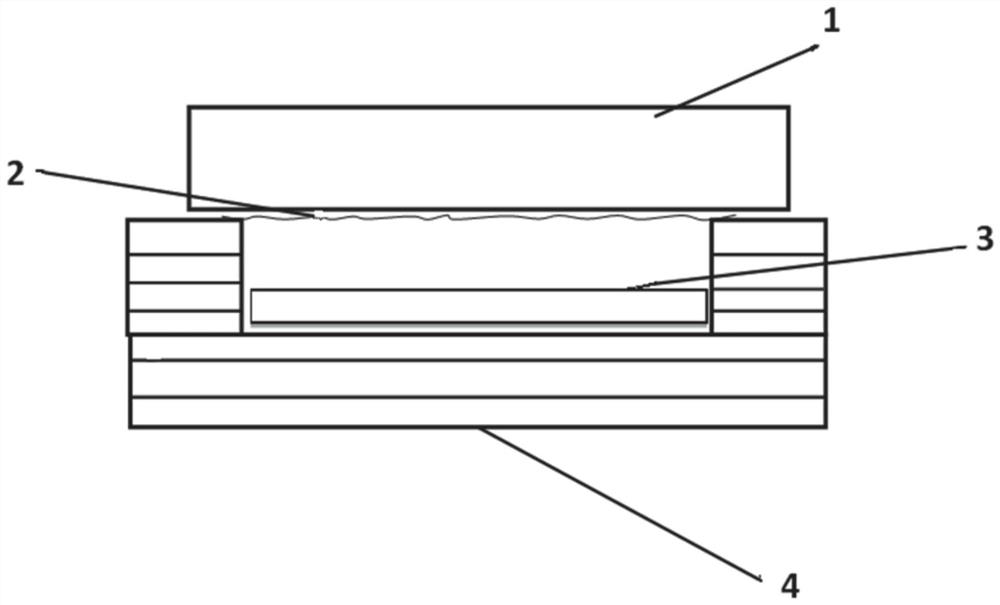

[0093] Step 3: the carbon nanotube film with a first substrate 1 upside down in a vessel containing the carbon 3 4, such as figure 1 Shown, and in which one end of a quartz tube. The present embodiment is a solid PMMA carbon powder preferably has a mass 20mg, quartz boat 4 container.

[0094] Step 4: Wash the reaction gas is introduced into the cavity until the cavity and clean air is excluded; as a cleaning gas is high purity argon gas 500sccm preferred embodiment of...

Embodiment 2

[0100] Step 1-2 consistent with the embodiment of Example 11-2;

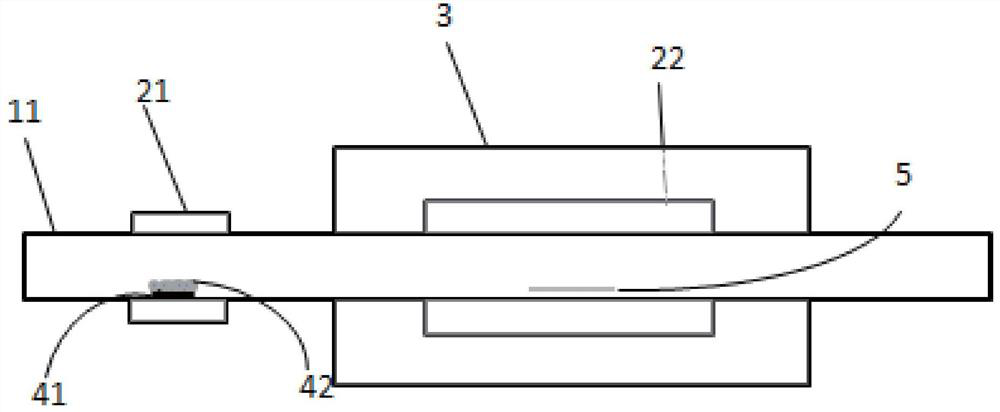

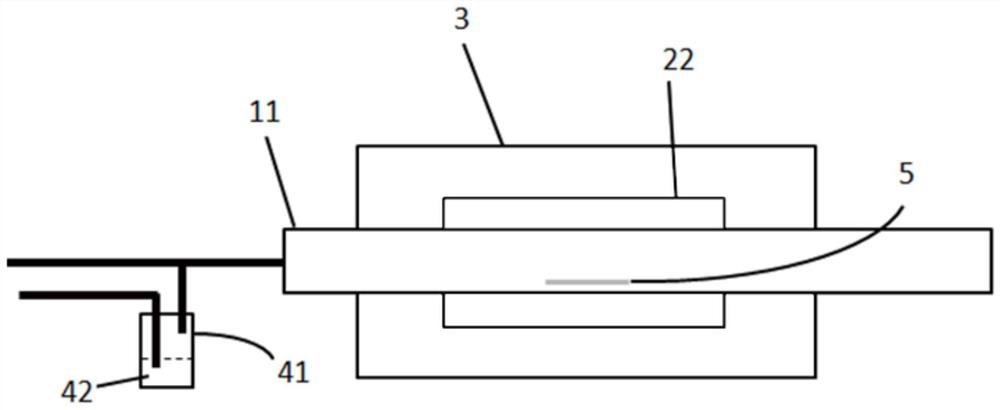

[0101] Step 3: A first carbon nanotube film with the substrate 1 is placed in the zone 22, as figure 2 , The carbon source is placed in the heating zone 21. The present embodiment is a solid carbon powder naphthyl, preferably mass 20mg, carbon filled container quartz boat.

[0102] Step 4: Wash the reaction gas is introduced into the cavity until the cavity and clean air is excluded; as a cleaning gas is high purity argon gas 500sccm preferred embodiment of the present embodiment, the washing time was 10min.

[0103] Step 5: After cleaning, adjustment meter, warmed to 22 to the temperature region T1 in an atmosphere of hydrogen and argon. After the temperature was stabilized, the temperature of the heating zone 21 reaches T2, a hold time of t1. In this embodiment, the hydrogen flow rate of 30 sccm, an argon gas flow rate of 300sccm, T1 is 400 ℃, T2 was 300 ℃, t1 is 40min.

[0104] In step 6-7 and step 6-7 in Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com