Treatment method of ciprofibrate process wastewater

A treatment method and technology for wastewater, which are applied in special treatment targets, water/sewage treatment, natural water treatment, etc., and can solve the problem of not mentioning the ciprofibrate process wastewater treatment method and the ciprofibrate purification wastewater treatment. methods, etc., to achieve the effects of easy industrial production, white appearance, and long service life of the adsorption resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

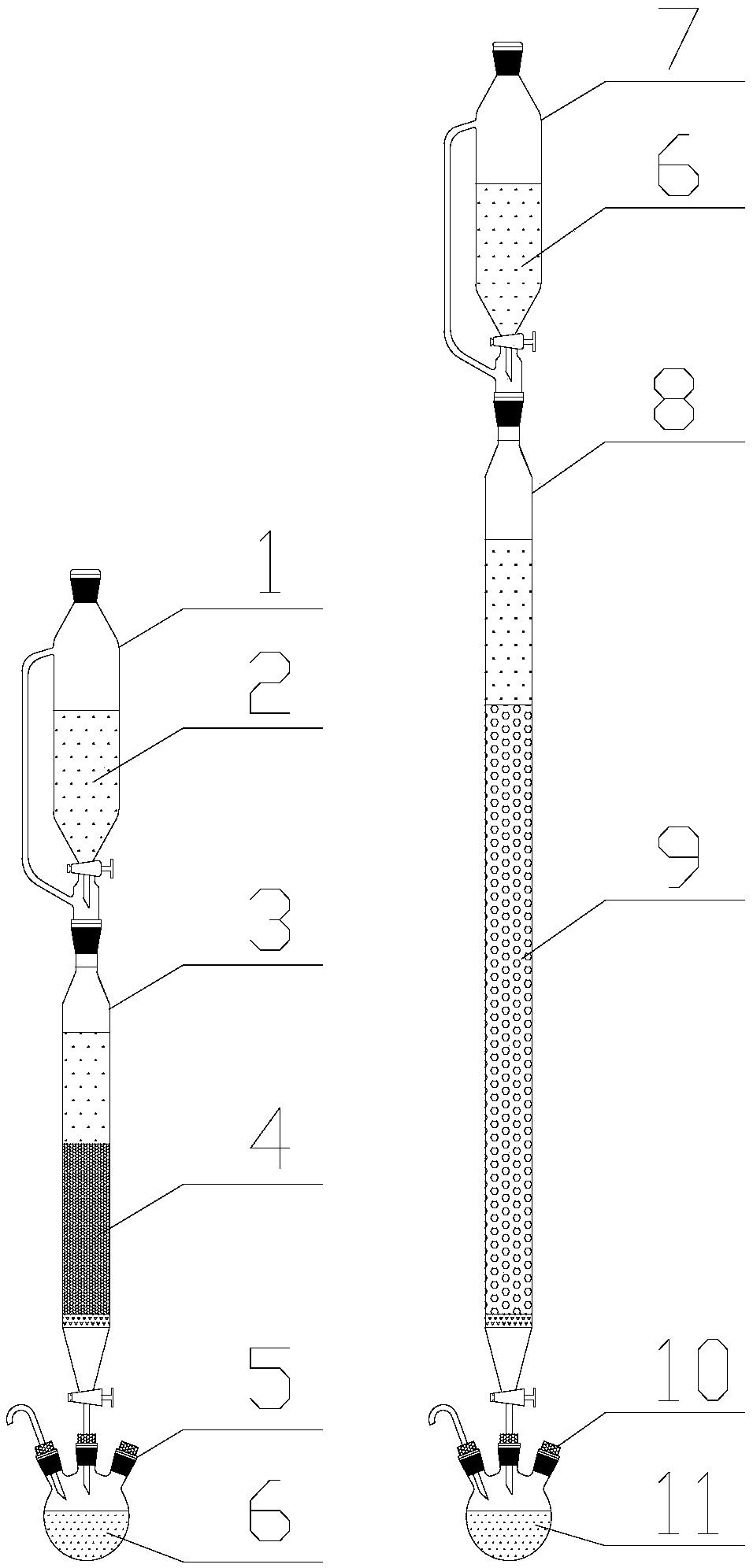

Image

Examples

Embodiment 1

[0037] Equilibrium adjustment: Add 500ml of ciprofibrate process wastewater into a clean 800ml beaker, the content of ciprofibrate detected by external standard is 0.51%, PH=7.5, stir constantly with a glass rod, and slowly add aqueous hydrochloric acid solution with a mass concentration of 20% Make balance adjustments. When the pH value of the wastewater reaches 5.5-7.0, stop adding the aqueous hydrochloric acid solution. Filtration to filter out the insoluble suspended matter in the wastewater.

[0038] Extraction: Transfer the well-balanced and adjusted waste water to a separatory funnel, and add 100ml of dichloromethane. Shake well and let stand. The dichloromethane in the lower layer was separated, and the recovered dichloromethane was used mechanically. The upper layer of wastewater is used for backup. According to the above-mentioned equilibrium adjustment and extraction method, 6 batches of waste water were processed again, and about 3000 ml of waste water after ex...

Embodiment 2

[0045] Equilibrium adjustment: Add 500ml of ciprofibrate process wastewater into a clean 800ml beaker, the content of ciprofibrate detected by external standard is 0.4%, pH=4.0, stir continuously with glass rod, slowly add caustic soda for equilibrium adjustment. When the pH value of the wastewater reaches 5.5-7.0, stop adding caustic soda. Filtration to filter out the insoluble suspended matter in the wastewater.

[0046] Extraction: Transfer the well-balanced and adjusted waste water to a separatory funnel, and add 100ml of dichloromethane. Shake well and let stand. The dichloromethane in the lower layer was separated, and the recovered dichloromethane was used mechanically. The upper layer of wastewater is used for backup. According to the above-mentioned equilibrium adjustment and extraction method, 6 batches of waste water were processed again, and about 3000 ml of waste water after extraction was obtained in total.

[0047] Activated carbon adsorption (continue to us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com