A kind of tungsten-nickel alloy and its preparation method

A technology of tungsten-nickel alloy and alloy powder, applied in the field of tungsten-nickel alloy and its preparation, can solve the problems of low alloy performance, increased melting temperature, large deformation stress, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, a tungsten-nickel alloy is provided, and the composition of the tungsten-nickel alloy is W: 20% and Ni: 80% in terms of mass percentage. The tungsten-nickel master alloy material is added, and the one-time feeding method is adopted.

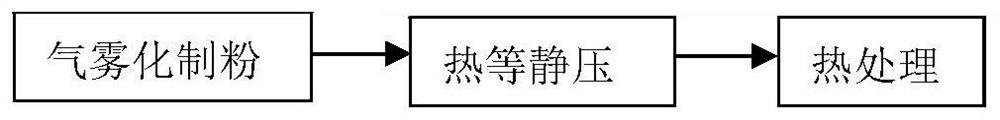

[0035] The preparation method of the tungsten-nickel alloy in the present embodiment is as figure 1 As shown, the following steps are included in sequence:

[0036] (1) Spray powder making step: the melting furnace temperature is 1600°C, the powder spray pressure is 10MPa, the protective atmosphere is argon, the collected powder passes through a 100-mesh sieve, and the yield of -100-mesh powder exceeds 70%;

[0037] (2) Hot isostatic pressing step: After the alloy powder obtained by gas atomization is encapsulated and exhausted, it is densified at high temperature and high pressure in a hot isostatic pressing furnace, wherein the pressing temperature is 1100 °C and the pressing pressure is 80 MPa. time 8h;

[0038] (...

Embodiment 2

[0042] In this embodiment, a tungsten-nickel alloy is provided, and the composition of the tungsten-nickel alloy is W: 80% and Ni: 20% in terms of mass percentage. The tungsten and nickel elemental metals are added, and a one-time feeding method is adopted.

[0043] The preparation of the tungsten-nickel alloy in the present embodiment comprises the following steps successively:

[0044] (1) Spray powder making step: gas atomization and melting, melting furnace temperature is 1850°C, powder spraying pressure is 30MPa, protective atmosphere is nitrogen, the collected powder is passed through a 500-mesh sieve, and the yield of -500-mesh powder exceeds 45%;

[0045] (2) Hot isostatic pressing step: After the alloy powder obtained by gas atomization is encapsulated and exhausted, it is densified at high temperature and high pressure in a hot isostatic pressing furnace, wherein the pressing temperature is 1450°C and the pressing pressure is 200MPa. The pressing time is 5h;

[004...

Embodiment 3

[0049] In this embodiment, a tungsten-nickel alloy is provided. The composition of the tungsten-nickel alloy is: W: 30%, Ni: 48%, Ta: 12%, and Nb: 10%. The tungsten-nickel element is added by tungsten-nickel master alloy, and other elements are added in simple form, and the one-time feeding method is adopted.

[0050] The preparation of the tungsten-nickel alloy in the present embodiment comprises the following steps successively:

[0051] (1) Spray powder making step: the melting furnace temperature is 1700°C, the powder spray pressure is 20MPa, the protective atmosphere is argon, the collected powder passes through a 250 mesh sieve, and the yield of -250 mesh powder exceeds 55%;

[0052] (2) Hot isostatic pressing step: After the alloy powder obtained by gas atomization is packaged and air-extracted, it is densified at high temperature and high pressure in a hot isostatic pressing furnace, wherein the pressing temperature is 1200°C and the pressing pressure is 130 MPa; The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com