Pipe pile verticality correcting method in construction process

A technology of verticality and pipe piles, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., and can solve the problems of easy breaking or cracking of prestressed pipe piles, failure of prestressed pipe piles to be welded to each other, and easy separation of prestressed pipe piles and other issues, to achieve the effect of short construction period, avoid waste, and improve integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The assembly of the pipe piles designed in this embodiment is greater than 10m, so it is necessary to connect the pipe piles. The pipe piles at the bottom have been driven into the foundation, and the verticality of the pipe piles at the bottom meets the requirements. The bottom and the top of the bottom pipe pile were welded, but after the second pipe pile was driven, it was found that the second pipe pile was tilted.

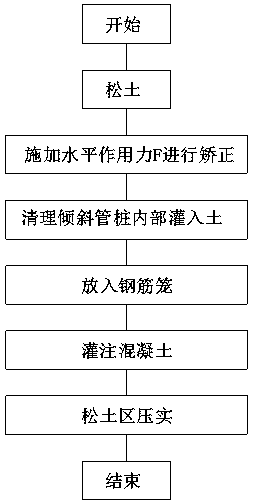

[0043] Refer to attached figure 1 The correction method shown is for the verticality correction of the second pipe pile.

[0044] Refer to attached figure 2 As shown, the verticality of the inclined pipe pile 1 is measured with the verticality measuring device. After the measurement, the verticality of the inclined pipe pile 1 is greater than 0.5% L, which does not meet the requirements of the construction specification for pipe piles. Therefore, the inclined pipe pile 1 needs to be Pile 1 is corrected for verticality. The correcting method adopts a...

Embodiment 2

[0052] combined with Figure 8 As shown, when the assembly of the pipe pile is less than 10m, or when the first pipe pile is driven when the pile needs to be connected, the problem of pipe pile inclination occurs, and the following construction steps are used to correct it.

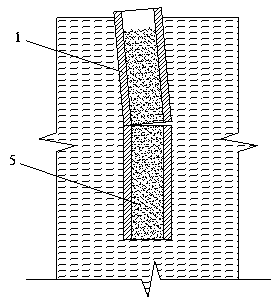

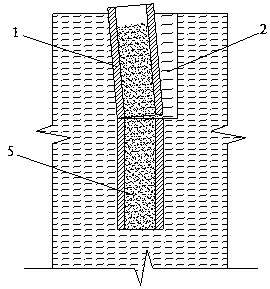

[0053] Step 1: Refer to the attached Figure 9 As shown, a drilling rig is used to loosen the soil away from the inclined direction of the inclined pipe pile 1 to form a soil loosening area 2 , and the depth of the loosening area 2 must be as deep as the driving depth of the inclined pipe pile 1 .

[0054] Step 2: Refer to the attached Figure 10 As shown, the drill bit of the thousand-meter drilling rig is inserted into the inclined pipe pile 1 several times. Since the inclined pipe 1 is inclined, the drill bit of the thousand-meter drilling rig is vertical, so the depth of each drilling of the thousand-meter drilling rig is not suitable. Too deep, too deep will cause the drill bit to break through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com