Automated workover rig for offshore platform and well repairing method

An offshore platform and workover rig technology is applied in drilling equipment and methods, earthwork drilling, drilling equipment and other directions to achieve the effects of improving safety, reducing potential safety hazards and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

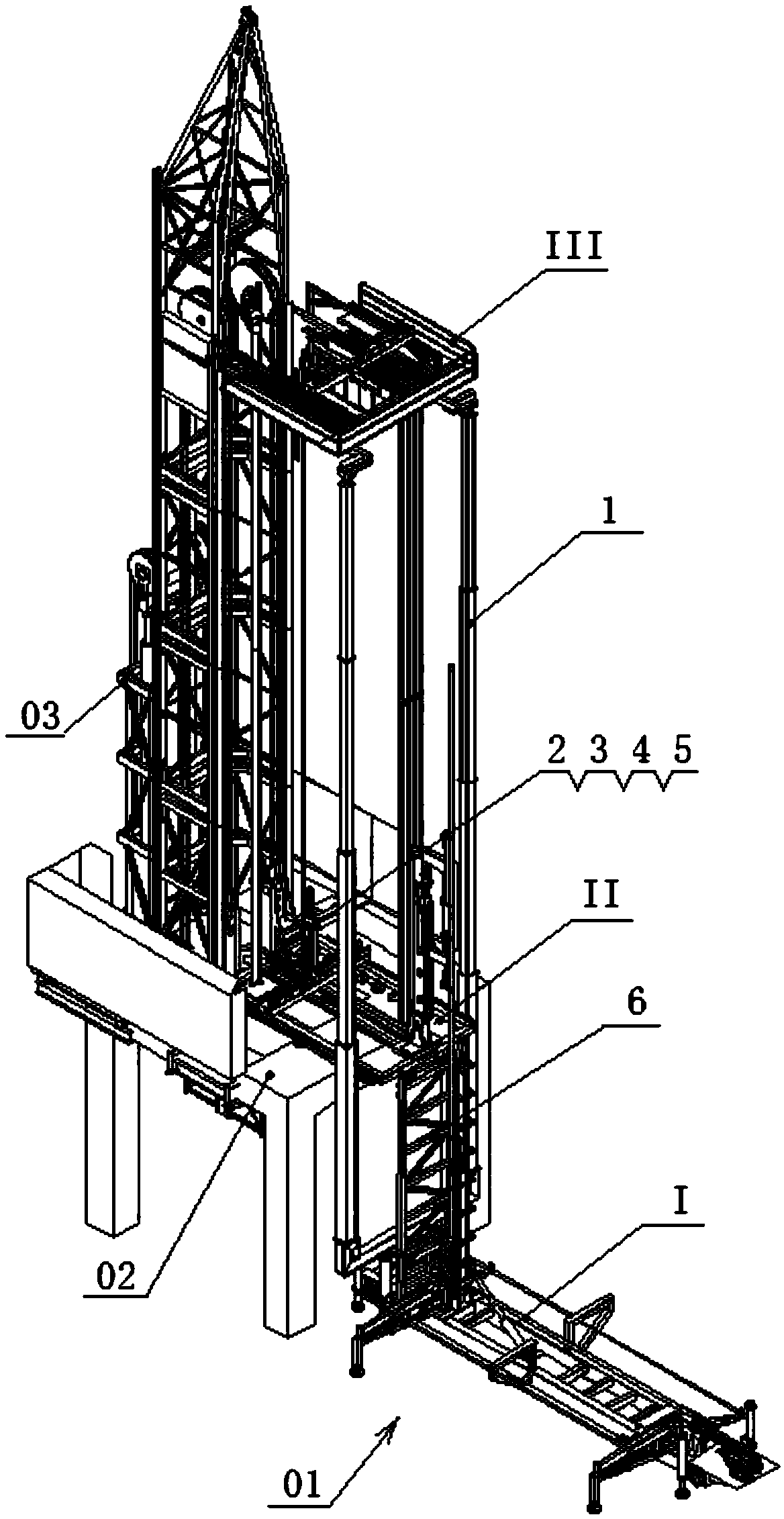

[0037] figure 1 Shown is the structural representation of the present invention.

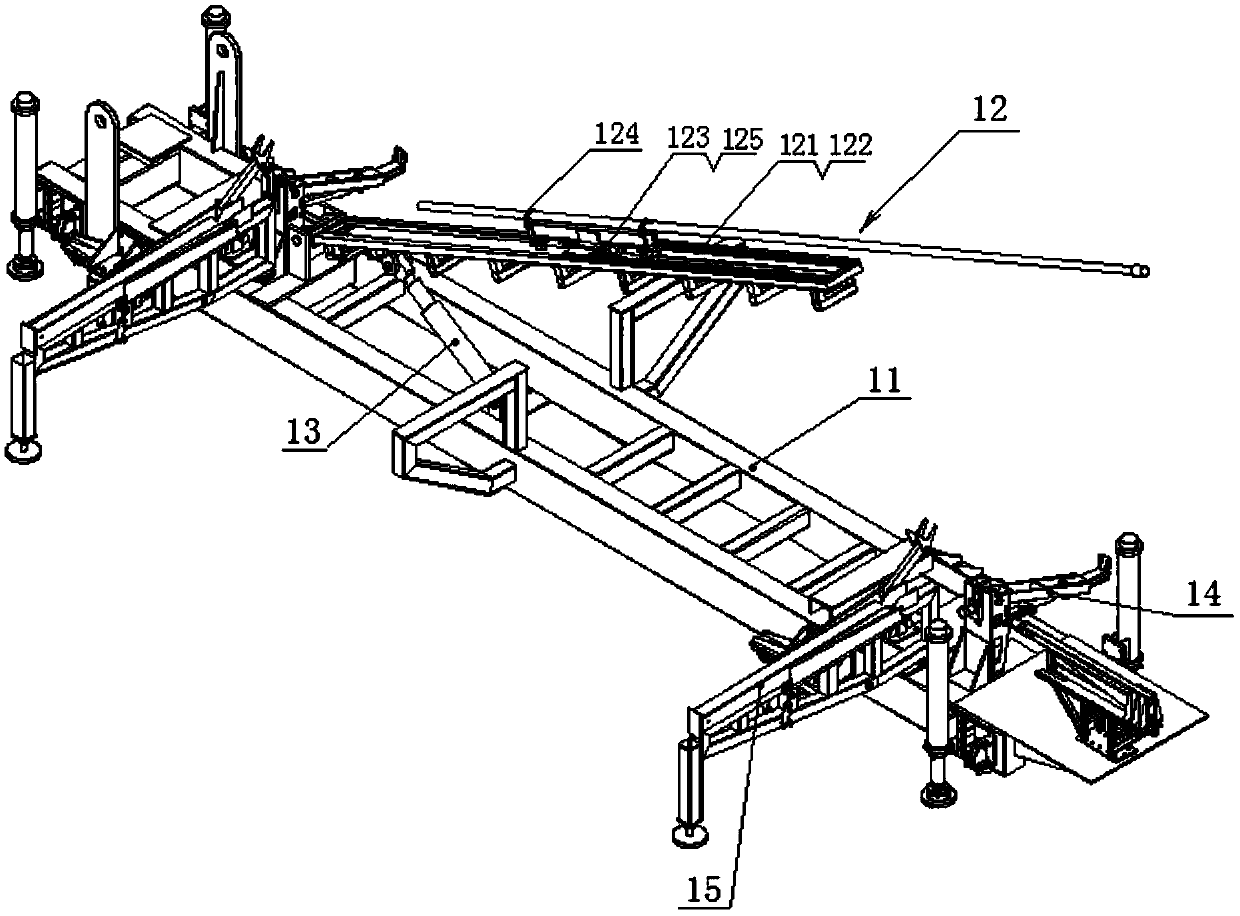

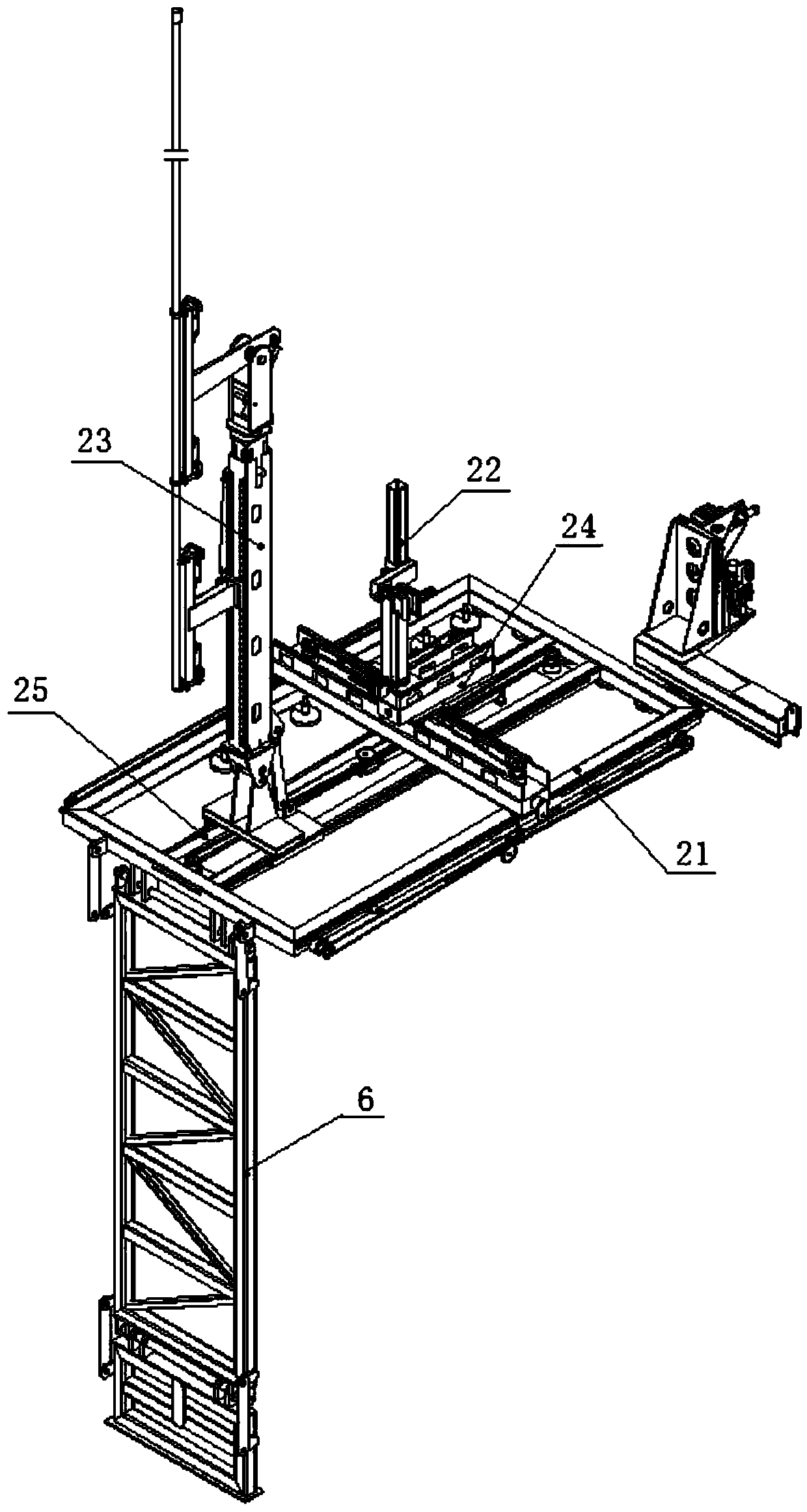

[0038]The present invention provides an automatic workover rig for an offshore platform, involving a deck 01, a drilling floor 02 and a derrick 03, including a chassis pipe lifting module I, a drilling floor upper and lower pipe module II, a second-floor code pipe module III, and a frame-shaped support column 1. Small support column 6, hydraulic control system and control center, the chassis lift pipe module 1 includes a chassis 11 and an upper pipe manipulator 12, the upper pipe manipulator 12 is arranged on the chassis 11, and the chassis 11 is installed on the deck 01, located at the drill One side of the support bottom of the platform 02; the bottom of the frame-shaped support column 1 is fixed on the chassis 11 near one end of the drill floor 02, and the small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com