Phase change electric heat storage heating system with working-condition-based PID and self-adaptive feedforward compensation and method

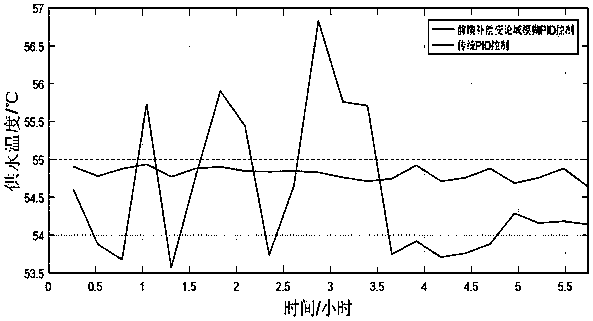

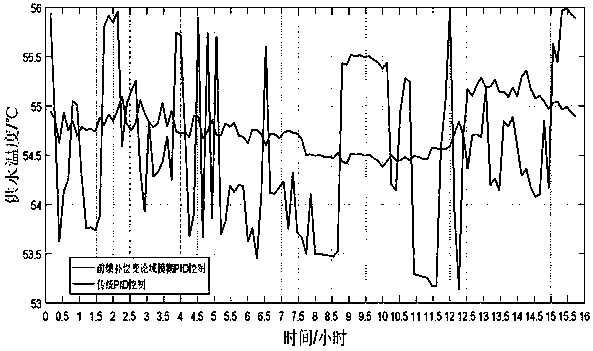

A heating system and feed-forward compensation technology, applied in the field of automation, can solve the problems of not meeting the requirements of dynamic characteristics of electrothermal energy storage control, large overshoot, and being susceptible to external interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

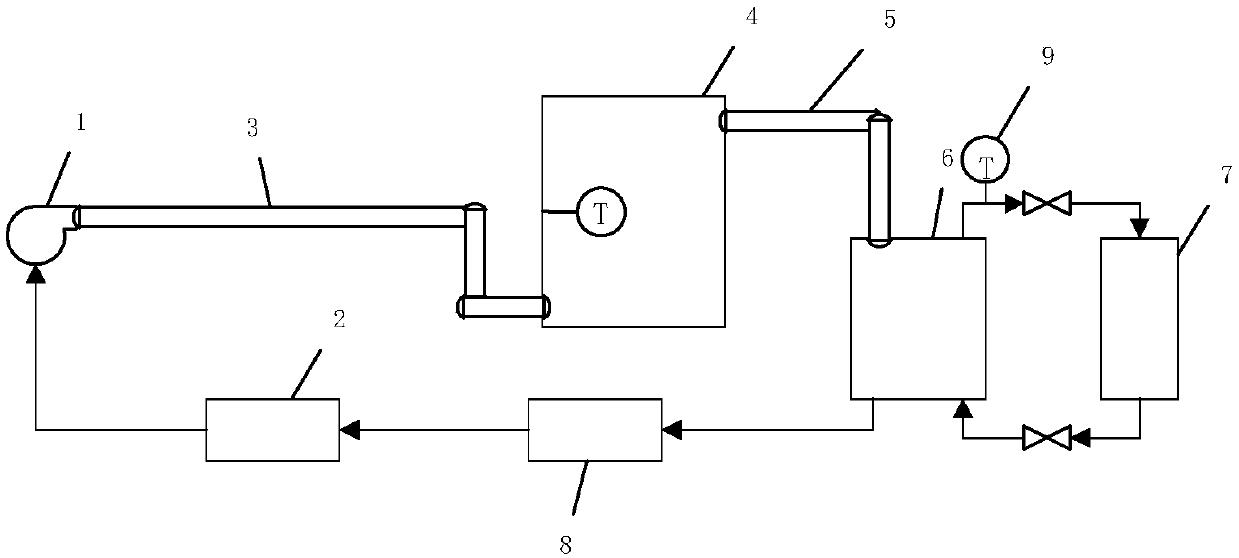

[0064] A PID + self-adaptive feed-forward compensation phase-change electric heat storage heating system according to working conditions, characterized in that the system includes an air circulation system and a water circulation system, and the water circulation system and the air circulation system exchange heat through a heat exchanger, and the output Heating hot water; the air circulation system includes a frequency conversion fan (1), a lower air duct (3), a phase change heat storage furnace (4) and an upper air duct (5);

[0065] The water circulation system includes a heat exchanger (6) and a heating pipeline (7);

[0066] The frequency conversion fan (1) is connected to the phase change heat storage furnace (4) through the lower air duct (3), and the phase change heat storage furnace (4) is connected to the heat exchanger (6) through the upper air duct (5), and the upper air duct (5) It is connected with the inlet port of the heat exchanger (6), and the heat exchanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com