Preparation device for sound absorbing sample and preparation method thereof

A technology for preparing devices and samples, applied in the field of sound-absorbing sample preparation, can solve problems such as gaps in test results, performance advantages and disadvantages, and impact on sound-absorbing test data results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Test sample requirements:

[0042] Substrate: thickness: 15±1mm, surface density: 1000g / m 2 ±50g / m 2

[0043] Size: 1005×1010mm

[0044] Fabric: black non-woven fabric (with PE powder on the back) 100g / m 2

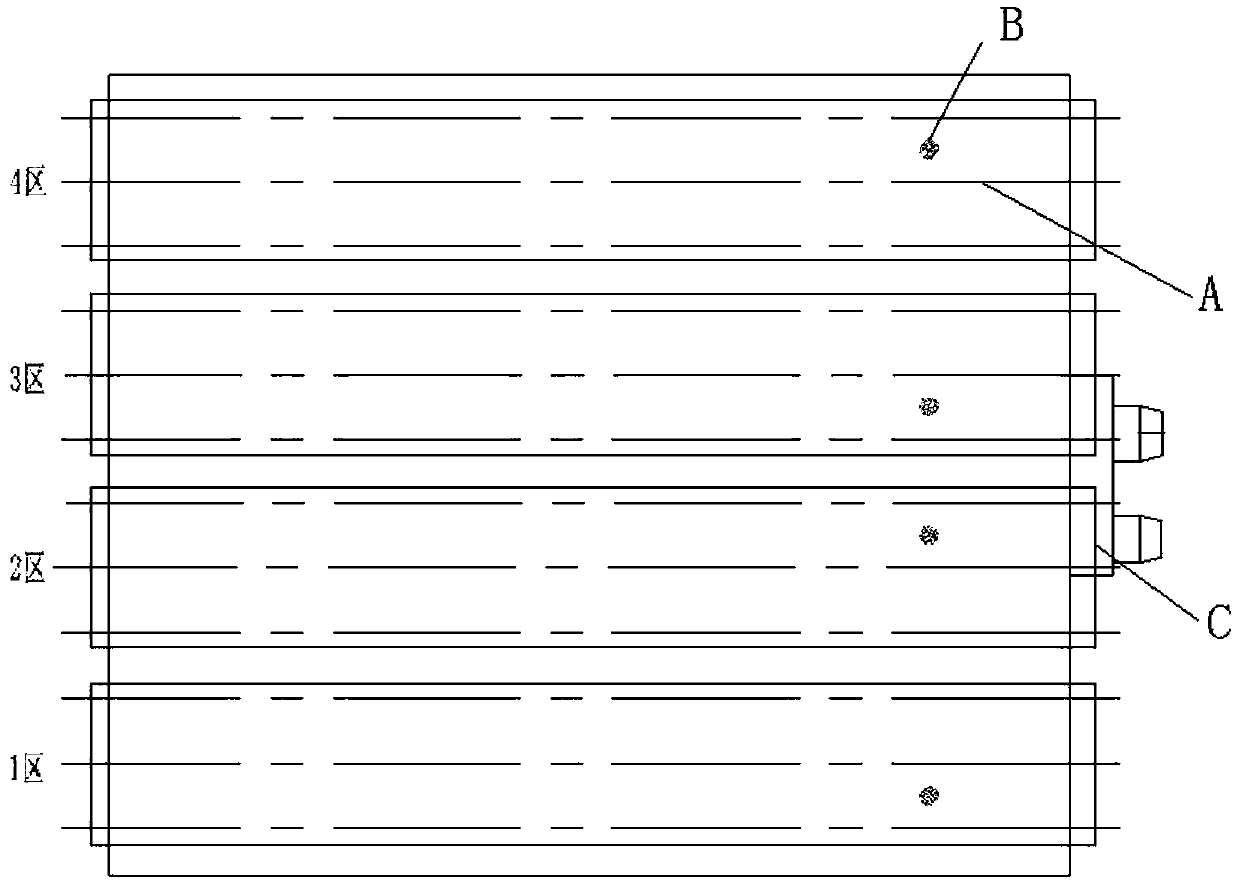

[0045] 4.1 Install the upper and lower plates in the four-column forming hydraulic press, connect the power supply, and adjust the temperature;

[0046] 4.2 Place four limit blocks with a thickness of 15mm respectively within 20mm from the edge of the lower plate to form a rectangular frame;

[0047] 4.3 Set the process parameters:

[0048] The four heating zones on the upper plate are at 160°C, the four heating zones on the lower plate are at 200°C, the hot-pressing time is 80S, and the hot-pressing pressure is 40MPa.

[0049] 4.4 will be 100g / m 2 Black non-woven fabric is laid flat at 1000g / m 2 Put the resin semi-cured felt on the center of the lower plate together, start the button to press, and check whether the thickness of the material meets the requi...

Embodiment 2

[0053] Test sample requirements:

[0054] Substrate: thickness: 10±1mm, surface density: 700g / m 2 ±50g / m 2

[0055] Size: 1005×1010mm

[0056] Fabric: black non-woven fabric (with PE powder on the back) 80g / m 2

[0057] 5.1 Install the upper and lower plates in the four-column forming hydraulic press, connect the power supply, and adjust the temperature;

[0058]5.2 Place four limit blocks with a thickness of 10mm respectively within 20mm from the edge of the lower plate to form a rectangular frame;

[0059] 5.3 Set the process parameters:

[0060] The four heating zones on the upper plate are at 160°C, the four heating zones on the lower plate are at 180°C, the hot-pressing time is 60S, and the hot-pressing pressure is 30MPa.

[0061] 5.4 will be 80g / m 2 The black non-woven fabric is laid flat on the 700g / m2 resin semi-cured felt, and then placed in the center of the lower plate, the button is activated to press, and the thickness of the material is checked from the c...

Embodiment 3

[0065] Test sample requirements:

[0066] Substrate: thickness: 30±1mm, surface density: 1600g / m 2 ±80g / m 2

[0067] Size: 1005×1010mm

[0068] Fabric: black non-woven fabric (with PE powder on the back) 180g / m 2

[0069] 6.1 Install the upper and lower plates in the four-column forming hydraulic press, connect the power supply, and adjust the temperature;

[0070] 6.2 Place four limit blocks with a thickness of 30mm respectively within 20mm from the edge of the lower plate to form a rectangular frame;

[0071] 6.3 Set the process parameters:

[0072] The four heating zones on the upper plate are at 190°C, the four heating zones on the lower plate are at 220°C, the hot-pressing time is 100S, and the hot-pressing pressure is 50MPa.

[0073] 6.4 will be 180g / m 2 The black non-woven fabric is laid flat on the 1600g / m2 resin semi-cured felt, and then placed in the center of the lower plate, the button is started to press, and the thickness of the material is checked from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com