Test method for compressing cold resistance coefficient of vulcanized rubber

A testing method and vulcanized rubber technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of potential safety hazards, low test efficiency, large test temperature fluctuations, etc., and achieve small test temperature fluctuation range and increase the number of instruments Utilization rate, effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

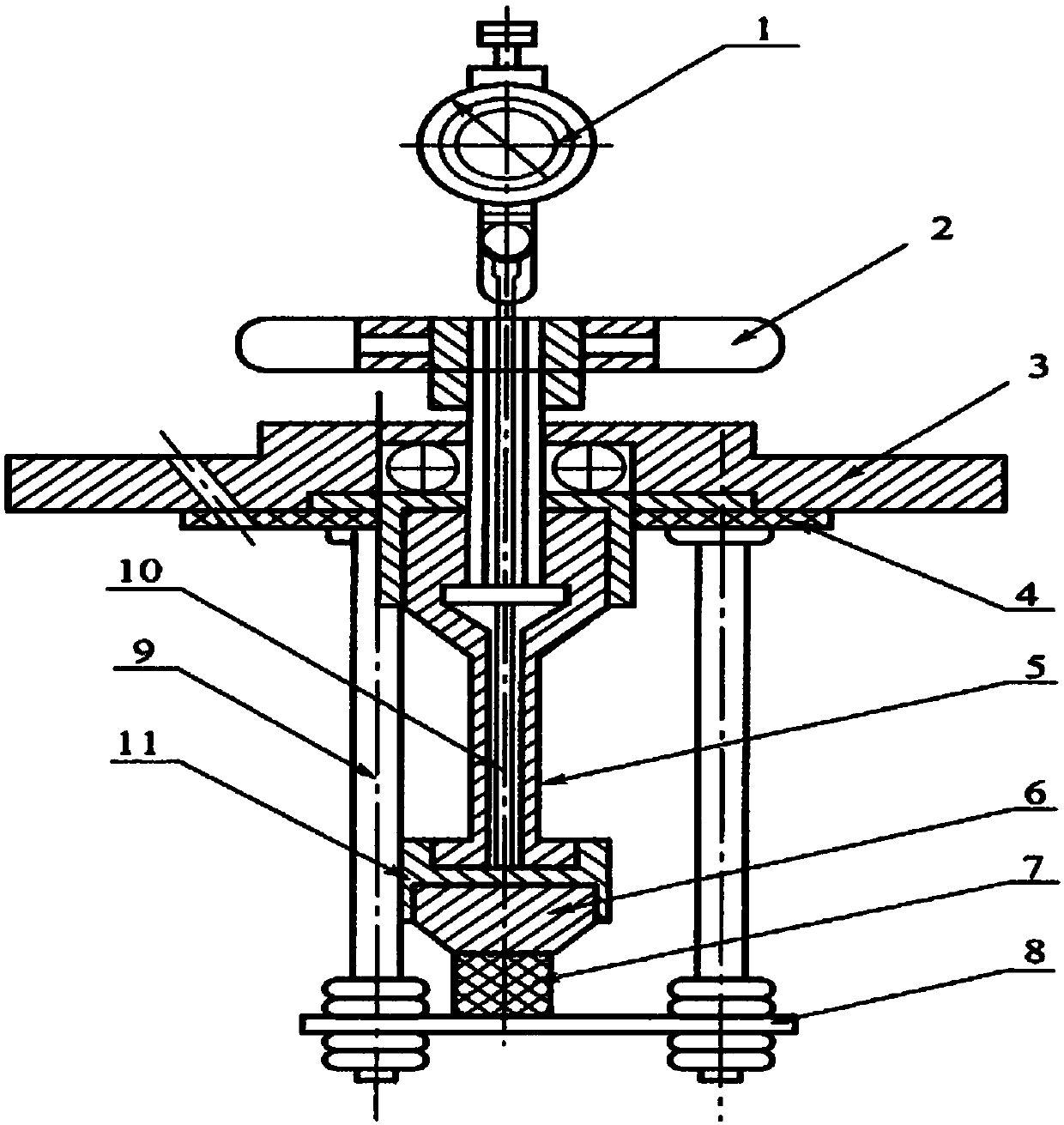

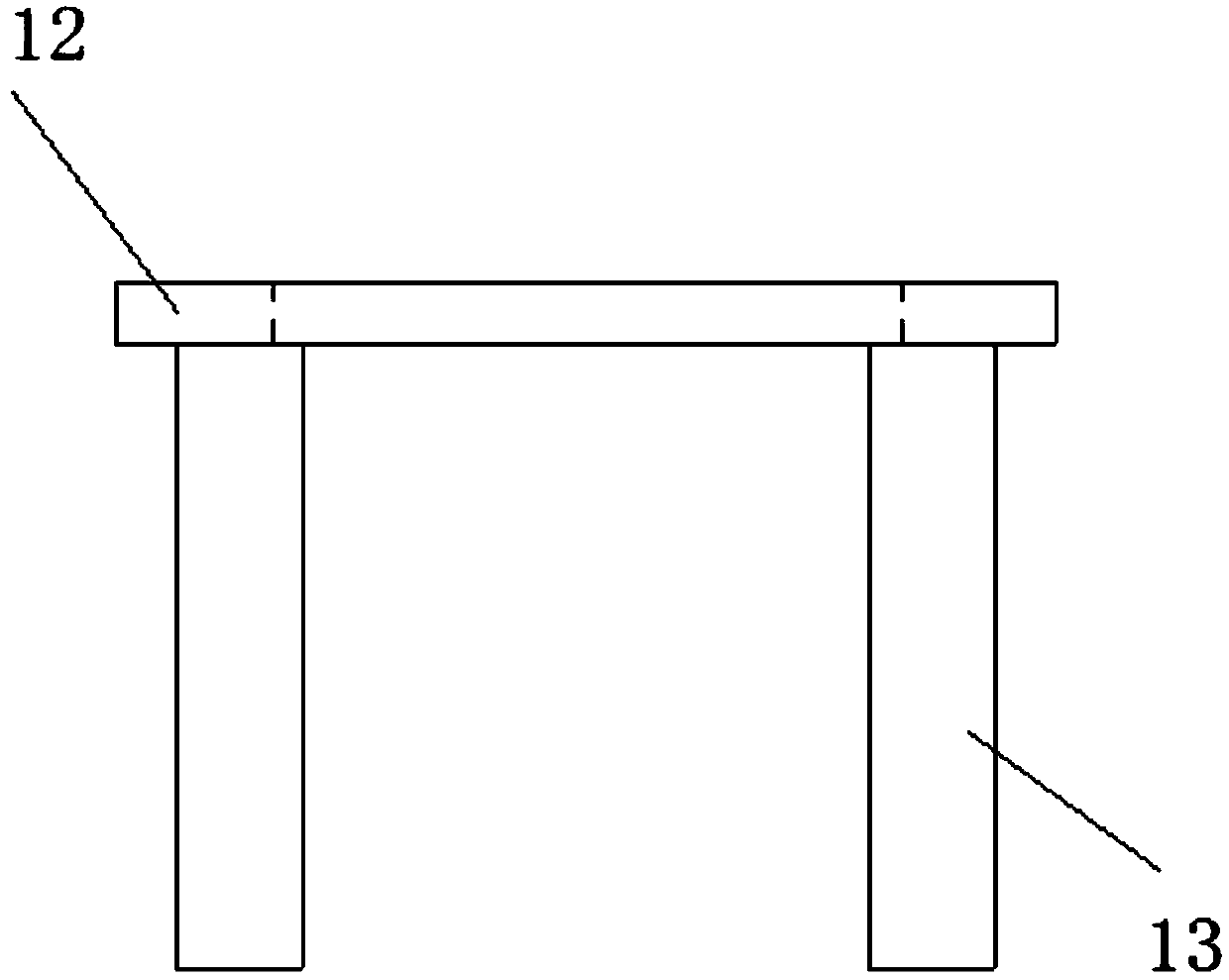

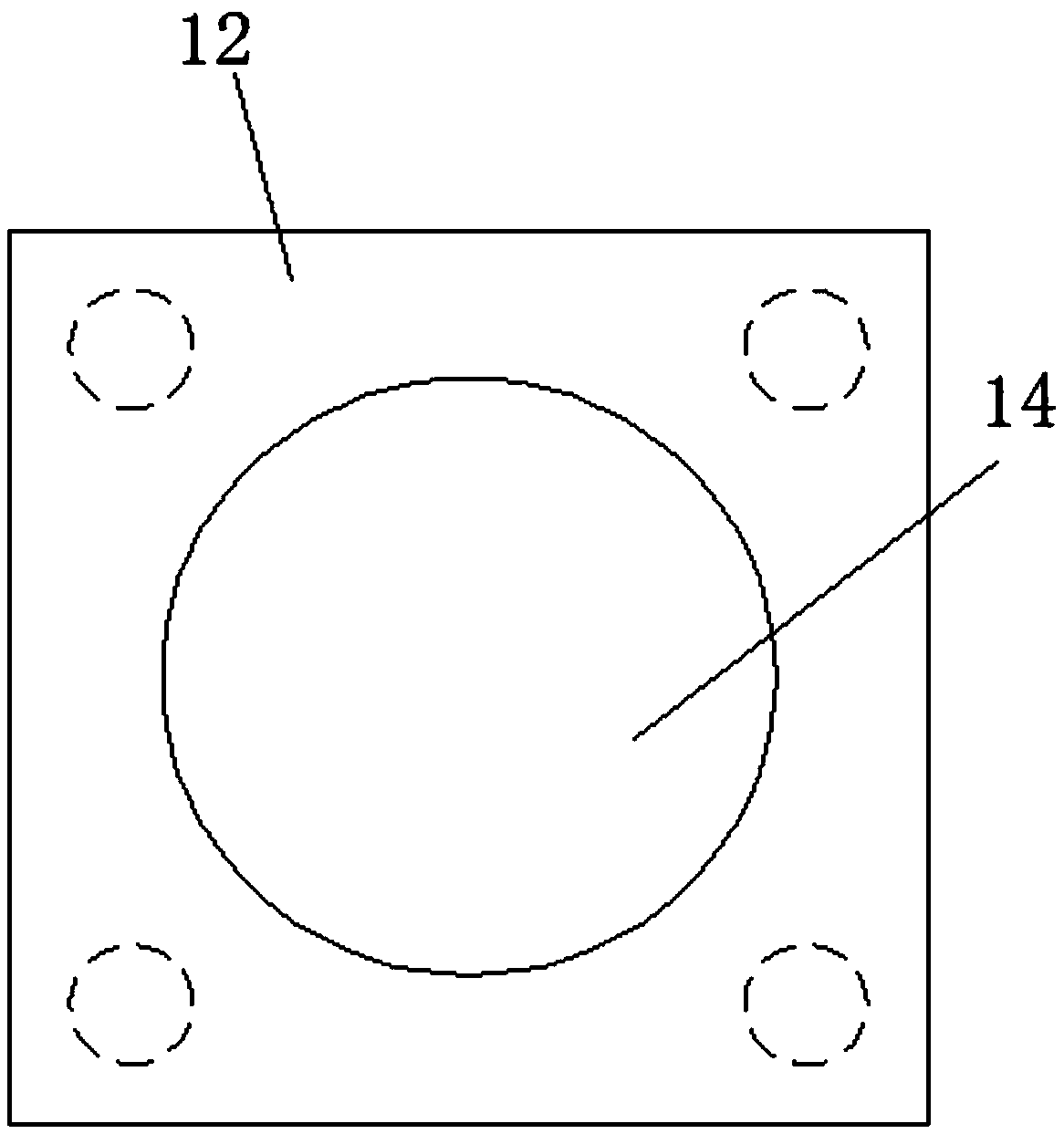

[0023] Such as Figure 1-4 As shown, a test method for the compression cold resistance coefficient of vulcanized rubber uses the compression device and the measuring device of the compression cold resistance tester. Pad 4, pole 9 and sleeve 11, the measuring device includes dial indicator 1 and connecting rod 10; the compression device is placed on the low temperature tank 15 of the low temperature embrittlement testing machine through the bracket, and the test temperature is controlled by the low temperature embrittlement testing machine. The test is implemented by a compression device and a measuring device; the support includes a top plate 12 and four table legs 13, and the center of the top plate 12 is provided with a circular hole 14; specifically includes the following steps:

[0024] Step 1: Add heat transfer medium alcohol 16 into the alcohol filling port of the low-temperature tank of the low-temperature embrittlement testing machine, and the injection amount ensures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com