Method for adjusting grating line parallel to line source

A line light source, grating engraving technology, applied in the field of spectral analysis, can solve the problems of light intensity, the device is not easy to operate, and it is difficult to clearly see the stripes, etc., to achieve the effect of simple operation and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

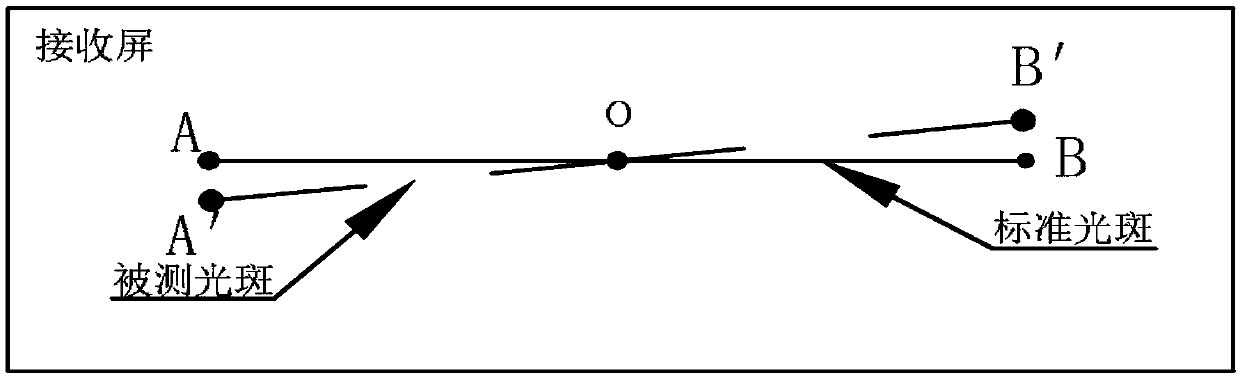

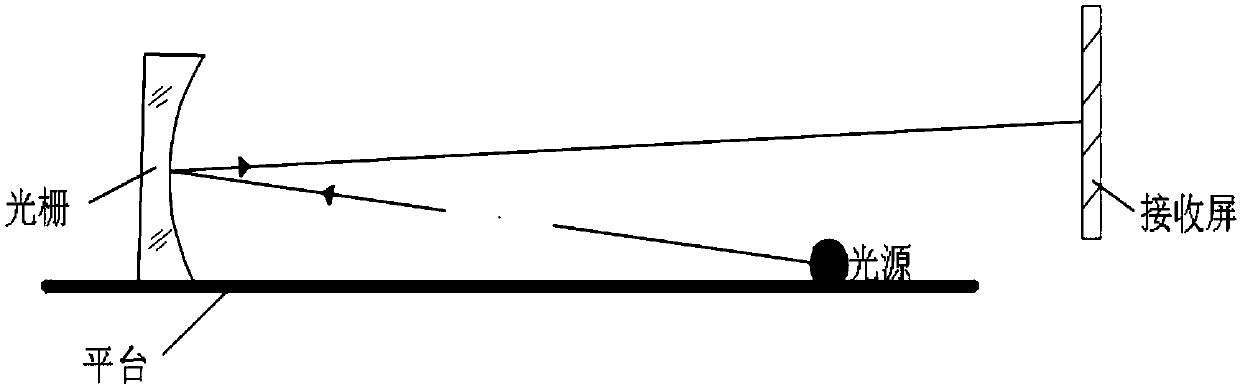

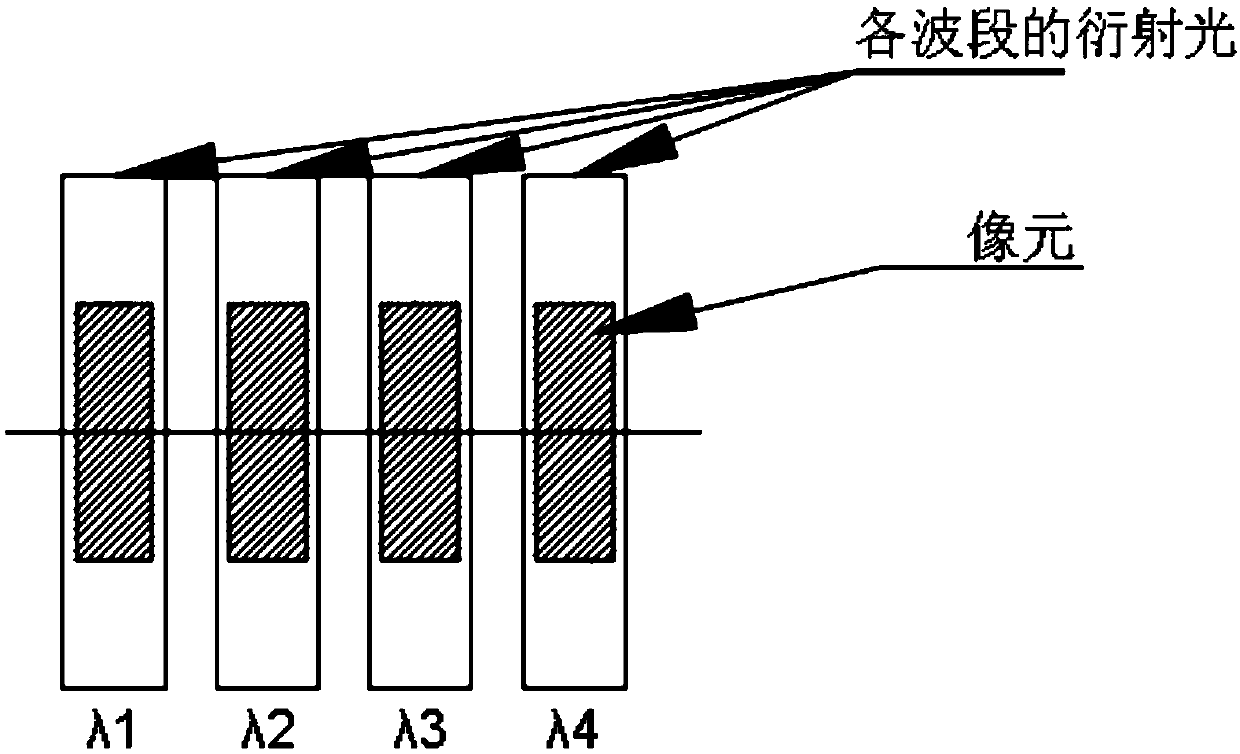

[0020] When the incident light is perpendicular to the grating surface, when the grating lines are not parallel to the line light source, the position of the 0th-order diffraction line remains unchanged, and the +1-order and -1-order diffraction spots are shifted upward and downward, respectively. , there is a phenomenon of unequal height, and it is slightly closer to the central zero-order diffraction spot. When the staggered angle between the grating reticle and the line light source increases, the offset distance of the +1 order and -1 order diffraction spots in the up and down direction Significantly increased. Generally, the linear array CCD is used to analyze the optical signal for spectral acquisition. The linear a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com