Preparation method and device of carbon nanotube/conductive polymer composite material

A technology of conductive polymers and carbon nanotubes, applied in the field of nanomaterials, can solve the problems of high equivalent internal resistance of electrode materials, restricting the development and industrialization of composite materials, and hindering the practical application of carbon nanotube composite materials, etc., to achieve rich Effects of economic value, efficiency improvement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

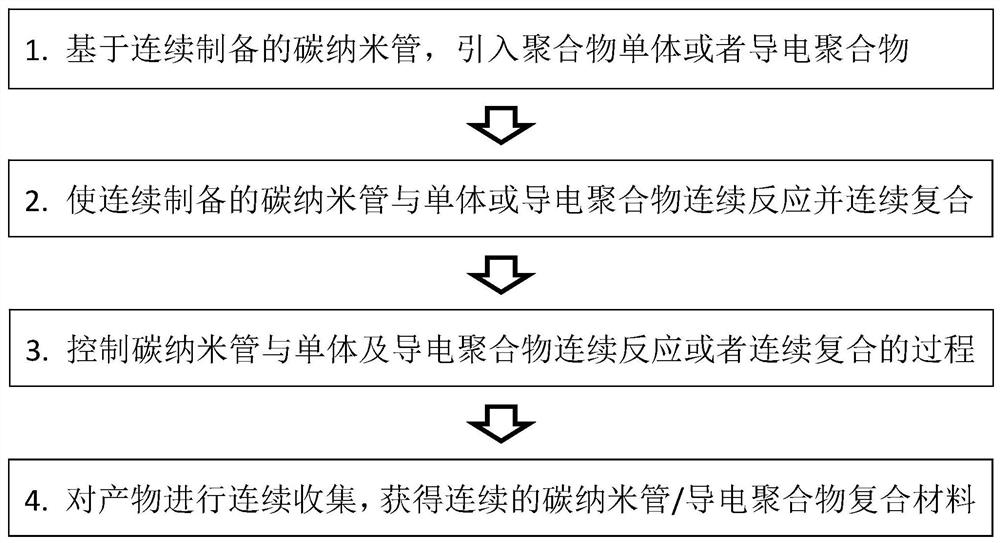

[0046] figure 1 It is a schematic flow chart of a method for preparing a carbon nanotube / conductive polymer composite material according to the present invention. Such as figure 1 Shown, the present invention provides a kind of preparation method of carbon nanotube / conductive polymer composite material (comprising composite film, composite strip and composite fiber), comprises the following steps:

[0047] Based on the continuous preparation of carbon nanotubes, the introduction of polymer monomers or conductive polymers;

[0048] Continuously react and continuously compound the continuously prepared carbon nanotubes with polymer monomers or with conductive polymers;

[0049] Control the process of continuous reaction and continuous compounding of carbon nanotubes with polymer monomers or conductive polymers, and regulate the actual reaction time with polymer monomers or the compounding amount of conductive polymers;

[0050] The product is collected continuously to obtain ...

Embodiment 1

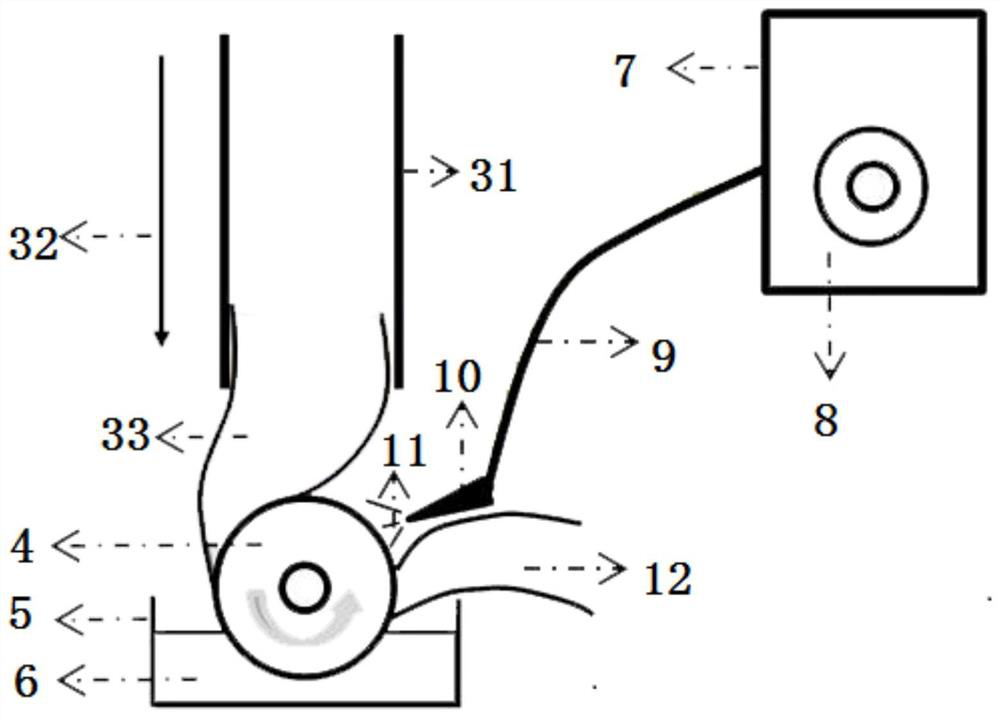

[0123] Such as image 3 shown in image 3 Among them, 31 is the outlet of the direct method preparation system of the continuous carbon nanotube film, 32 is the lead-out direction of the continuous carbon nanotube film in the preparation system 1, 33 is the continuous carbon nanotube film, and 4 is the unwinding roller (including the flexible substrate) , can also be used as a guide roller (without substrate), 5 is a reaction vessel (such as: glass reaction tank), 6 is a reaction solution (such as: containing polymer monomer), 7 is an oxidant introduction device (such as: a peristaltic pump), 8 is an oxidant, 9 is a conduit, 10 is a nozzle, 11 is a paper brush, and 12 is a product, namely a composite film. The composite film is collected with a collection system.

[0124] 1) Prepare system 1 by inflation aerosol method, such as image 3 As shown, a continuous carbon nanotube film 33 with a diameter of 0-100 mm is obtained at the outlet end driven by the carrier gas. Optiona...

Embodiment 2

[0140] Figure 4 It is a schematic diagram of the continuous preparation method and device of the carbon nanotube / conductive polymer composite material in one embodiment of the present invention. exist Figure 4 Among them, 41 is the carbon nanotube array used for the system of indirect preparation of continuous carbon nanotube film by array wire drawing method, 42 is the pulling direction of the continuous carbon nanotube film in 41, 43 is the continuous carbon nanotube film prepared by indirect method, 4 It is an unwinding roller (including a flexible substrate, the material is not limited; the conductivity is not limited, that is, an insulator or a conductor), and it can also be used as a guide roller (excluding the substrate). 5 is a reaction container (such as: a glass reaction tank), 6 Reaction solution (such as: containing polymer monomer), 7 is an oxidizing agent introduction device (such as: peristaltic pump), 8 is an oxidizing agent, 9 is a conduit, 10 is a nozzle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com