Vacuum interrupter, vacuum DC high voltage relay and preparation method thereof

A technology of vacuum interrupter and DC high voltage, applied in relays, high-voltage air circuit breakers, high-voltage/high-current switches, etc., can solve the problems of high raw material cost, polluted environment, cumbersome production process, etc., and achieve good thermal stability, The effect of high vacuum preservation density and simple operation of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

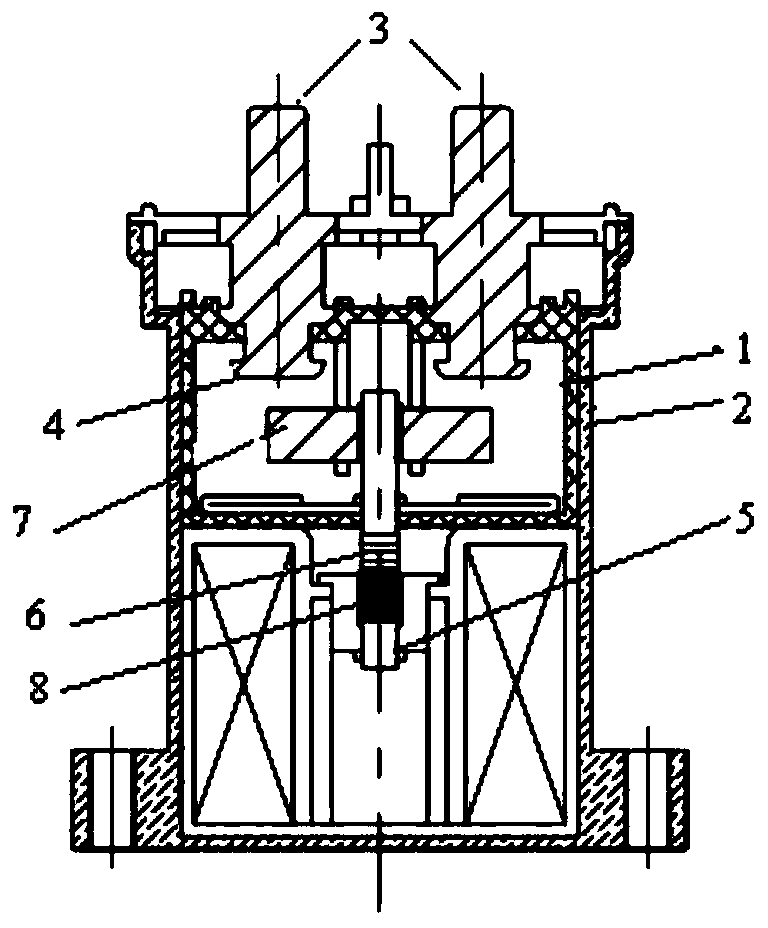

[0034] According to another aspect of the present invention, there is also provided a method for preparing a vacuum DC high-voltage relay, comprising the following steps: preparing ceramic glue for standby; coating the step of the conductive rod 3 with ceramic glue, and inserting it into the end of the ceramic inner cavity 1 In the hole, after standing still, fasten the contact 4 on the conductive rod 3, coat the insert end of the support rod 5 with ceramic glue, insert it into the center hole of the ceramic inner cavity 1, install the clamping plate, after standing still, Mount spring 6 and conductive block 7 on support rod 5, coat ceramic glue on the outer surface of ceramic inner cavity 1, after standing, vacuumize and seal; electromagnetic inductor 8 is packed into the bottom of open plastic outer shell 2, and Match the ceramic inner cavity 1 with the electromagnetic inductor 8, put the ceramic inner cavity 1 into the electromagnetic inductor 8 to match the upper end, fill ...

Embodiment 1

[0039] vacuum interrupter

[0040] In terms of parts by mass, alumina 93, high density 1.95, calcium carbonate 3.25, silicon dioxide 1.28, magnesium oxide 0.7, each material was weighed and dry-milled in a ball mill with a material-to-ball ratio of 1:1.8, and the ball mill was discharged for 36 hours to obtain ceramics Mix the powder, weigh the wax, the wax ratio is 15% of the mass percentage of the material, heat it into the blender, and control the temperature at 1080 ° C, after the wax is completely melted, then add the ceramic mixed powder, stir for 6 hours, and stir evenly Finally, put it into the hot die casting machine, keep it warm at 80°C, use the mold and high-pressure air to inject the mold, the pressure is above 0.6MPa, and demould after cooling. Send the biscuit-fired bowl to dewax at 1050°C, and then sinter it into porcelain at 1650°C. The ceramic inner cavity 1 that is qualified for use after inspection.

[0041] In terms of parts by mass, PPS75, ceramic powde...

Embodiment 2

[0047] vacuum interrupter

[0048] In terms of parts by mass, alumina 92, high density 2.5, calcium carbonate 3, silicon dioxide 2, magnesium oxide 0.5, each material was weighed and dry-milled in a ball mill, the ratio of material to ball was 1:2, and the ball mill was discharged for 36 hours to obtain ceramics Mix the powder, weigh the wax, the wax ratio is 18% of the mass percentage of the material, heat it into the blender, and control the temperature at 1050°C, after the wax is completely melted, add the ceramic mixed powder, stir for 6 hours, and stir evenly Finally, put it into the hot die casting machine, keep it warm at 80°C, use the mold and high-pressure air to inject the mold, the pressure is above 0.6MPa, and demould after cooling. Send the biscuit-fired bowl to dewax at 1100°C, and then sinter it into porcelain at 1700°C. The ceramic inner cavity 1 that is qualified for use after inspection.

[0049] In terms of parts by mass, PPS780, ceramic powder 15, and gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com