Purging joint device and purging system

A joint device and purging gas technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to avoid waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

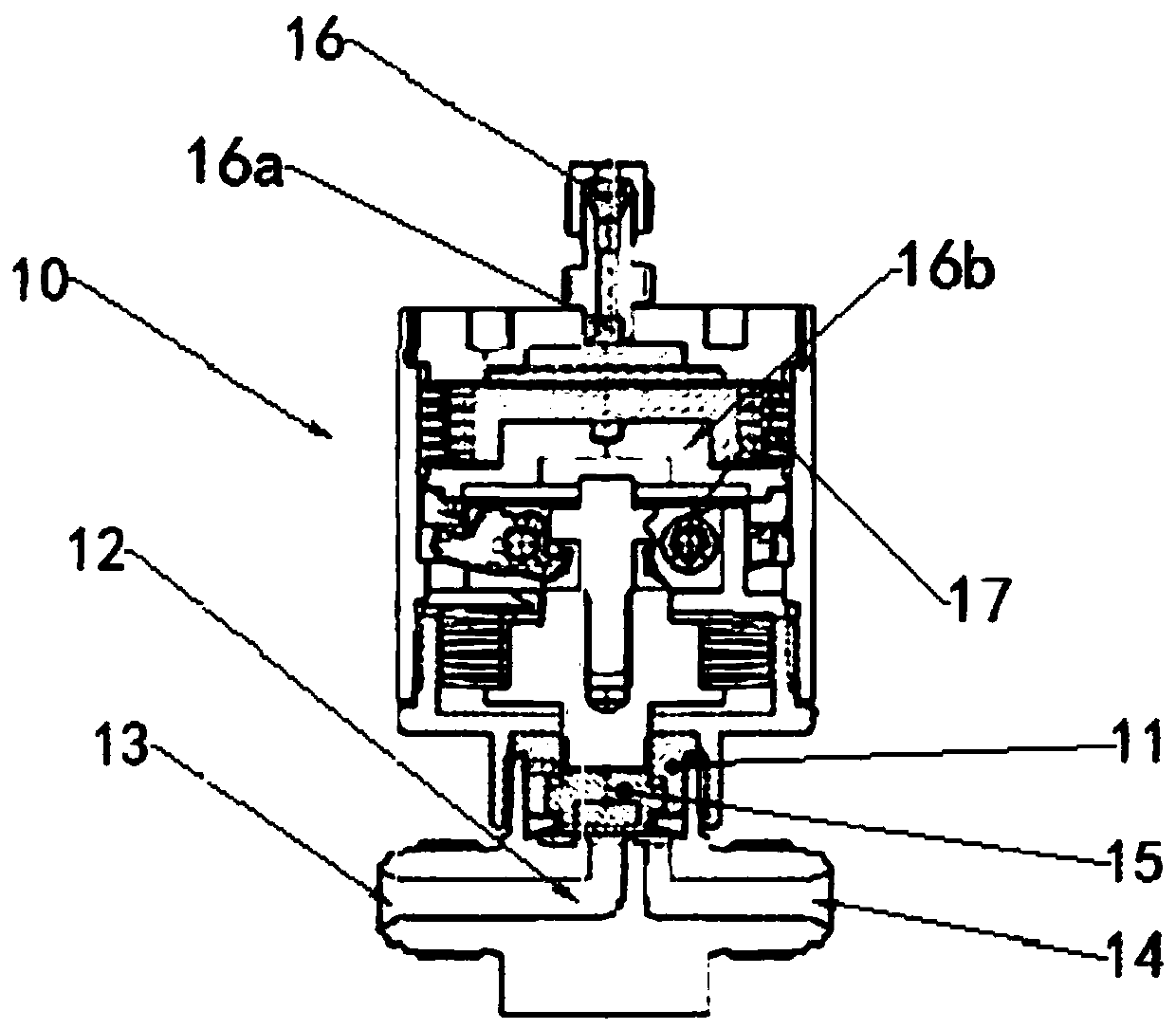

[0033] figure 1 It is a schematic diagram of a purge joint device in the embodiment of the present application.

[0034] refer to figure 1 , the present embodiment provides a purge joint device 10, comprising: a housing 11, an air passage 12, a piston 15 and a switch 16; the air passage 12 is arranged in the housing 11, wherein one end of the air passage 12 It is the purge gas inlet 13, which is connected to a purge gas source 30, and the other end of the gas channel 12 is the purge gas outlet 14, and the purge gas outlet 14 is 14 is connected with a device 20 to be purged; the piston 15 is movably arranged in the housing 11 for opening or blocking the air passage 12, and the switch 16 is connected with the piston 15 for It is used to control the piston 15 to block or open the air passage 12 .

[0035] The switch 16 is a gas-driven switch 16, the switch 16 includes a stopper 16b, the stopper 16b is provided with a driving gas interface 16a connected to a driving gas source,...

Embodiment 2

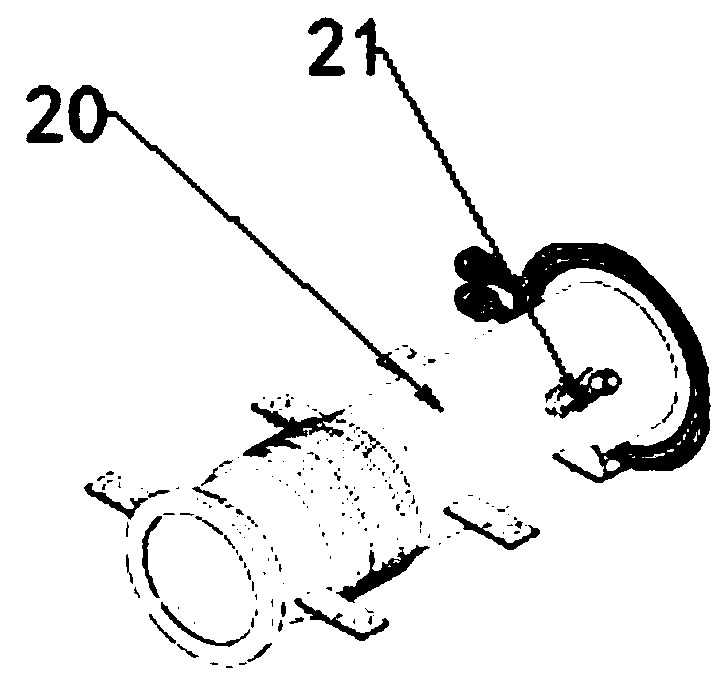

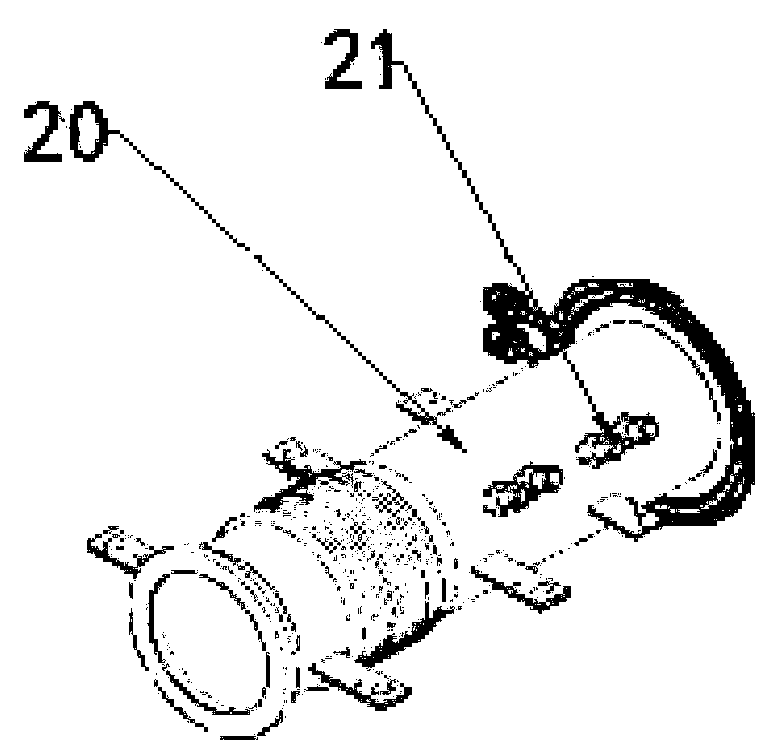

[0040] figure 2 is a schematic diagram of a device to be purged in the embodiment of the present application, image 3 is a schematic diagram of another device to be purged according to the embodiment of the present application, Figure 4 It is a schematic diagram of a purging system in the embodiment of the present application.

[0041] On the other hand, this embodiment provides a purging system, see Figure 4 , the purging system includes a purge gas source 30, a gas flow controller 40, a purge joint device 10 and a device to be purged 20; the purge gas source 30, the gas flow controller 40 and the purge The purge joint devices 10 are connected to each other through gas pipelines, and one end of the gas flow controller 40 is connected to the purge joint device 10, so as to conduct the purge gas source 30 passing into the device 20 to be purged. Flow control, so as to adjust the pressure of the purge gas source 30 in the pipeline, can rationally use the purge gas source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com