Anti-rotation bolt assembly for conductive use

A bolt assembly and application technology, applied in the field of anti-rotation bolt assemblies, to achieve the effects of easy processing, high strength and toughness, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

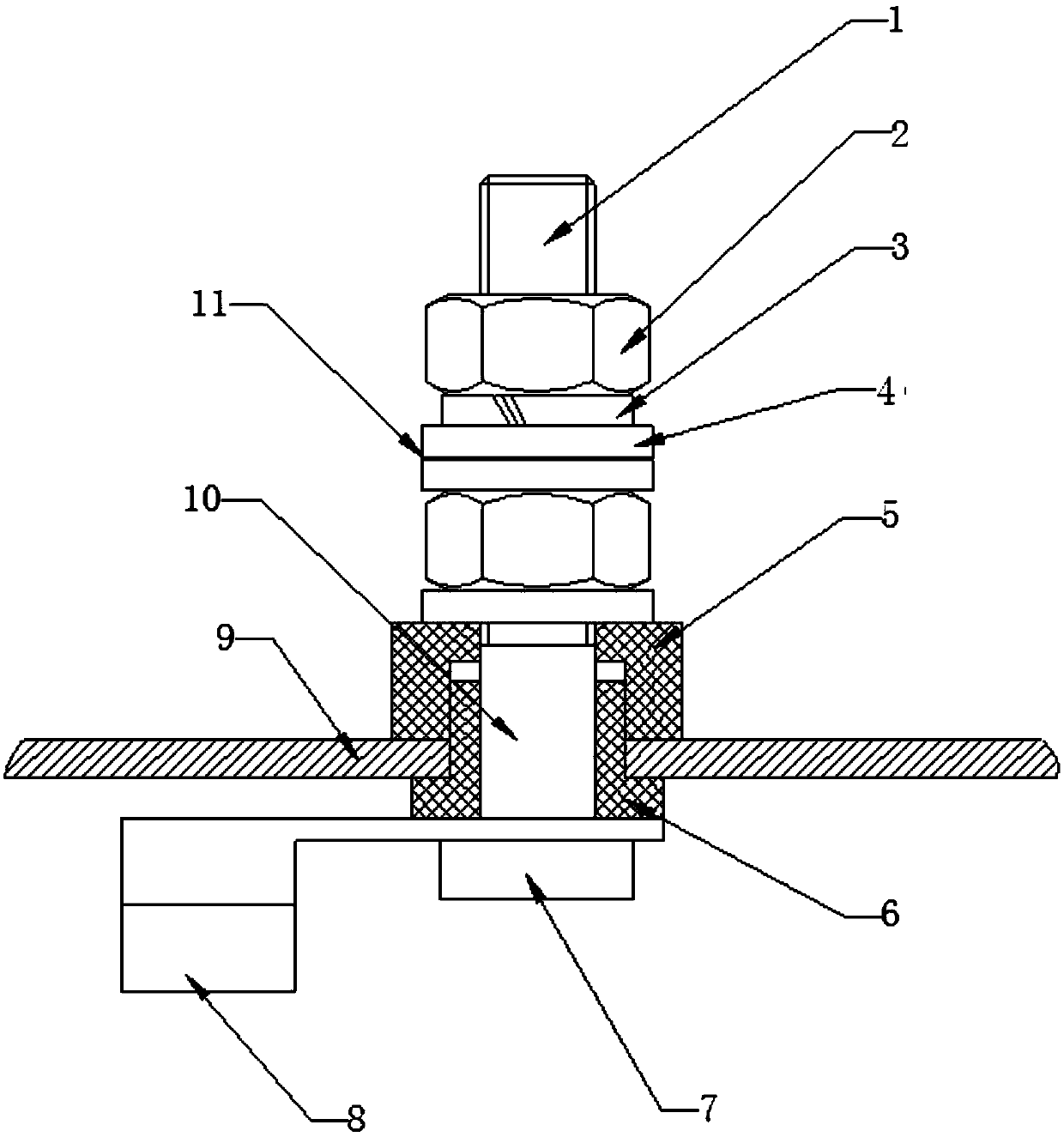

[0034] The invention provides an anti-rotation bolt assembly for conductive purposes, comprising:

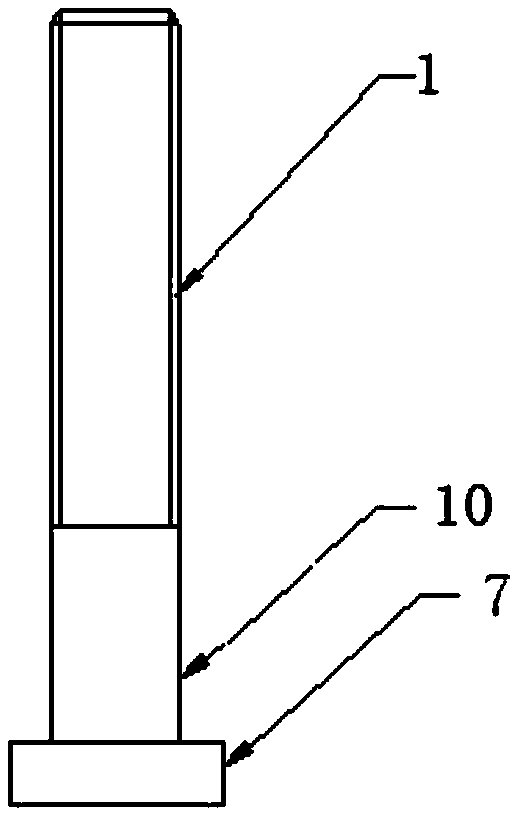

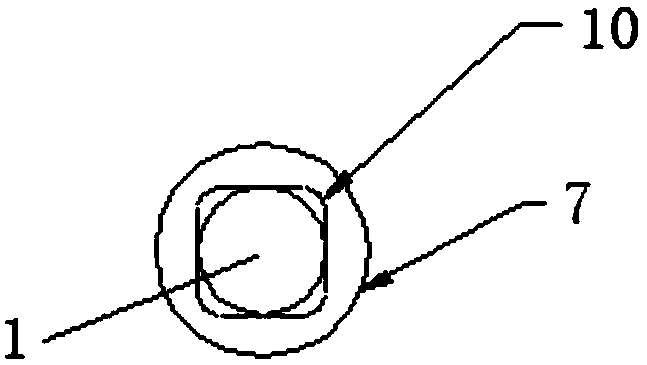

[0035] Bolt, described bolt comprises bolt cap 7, square screw rod 10 and round screw rod 1 successively from bottom to top, described bolt cap 7, square screw rod 10 and round screw rod 1 are fixedly connected or integrally formed, and described round screw rod The outer surface of 1 is provided with threads;

[0036] A crimping assembly, the crimping assembly is sleeved on the circular screw 1 and threadedly connected with the circular screw 1;

[0037] An insulating assembly, the insulating assembly is sleeved on the square screw 10, and is used to realize the insulation between the bolt and the housing 9;

[0038] A connection terminal, the connection terminal is provided with an inner hole suitable for the square screw 10 , the inner control is sleeved on the lower part of the square screw 10 and is in contact with the bolt cap 7 .

[0039] Further, the wire crimping asse...

Embodiment 2

[0045] The invention provides an anti-rotation bolt assembly for conductive purposes, comprising:

[0046] Bolt, described bolt comprises bolt cap 7, square screw rod 10 and round screw rod 1 successively from bottom to top, described bolt cap 7, square screw rod 10 and round screw rod 1 are fixedly connected or integrally formed, and described round screw rod The outer surface of 1 is provided with threads;

[0047] A crimping assembly, the crimping assembly is sleeved on the circular screw 1 and threadedly connected with the circular screw 1;

[0048] An insulating assembly, the insulating assembly is sleeved on the square screw 10, and is used to realize the insulation between the bolt and the housing 9;

[0049] A connection terminal, the connection terminal is provided with an inner hole suitable for the square screw 10 , the inner control is sleeved on the lower part of the square screw 10 and is in contact with the bolt cap 7 .

[0050] Further, the wire crimping asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com