Industrial shrimp shell filtering machine

A technology for industrial use and filter shell, applied in the field of industrial shrimp filter shell machine, to avoid damage, ensure integrity, and avoid re-mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

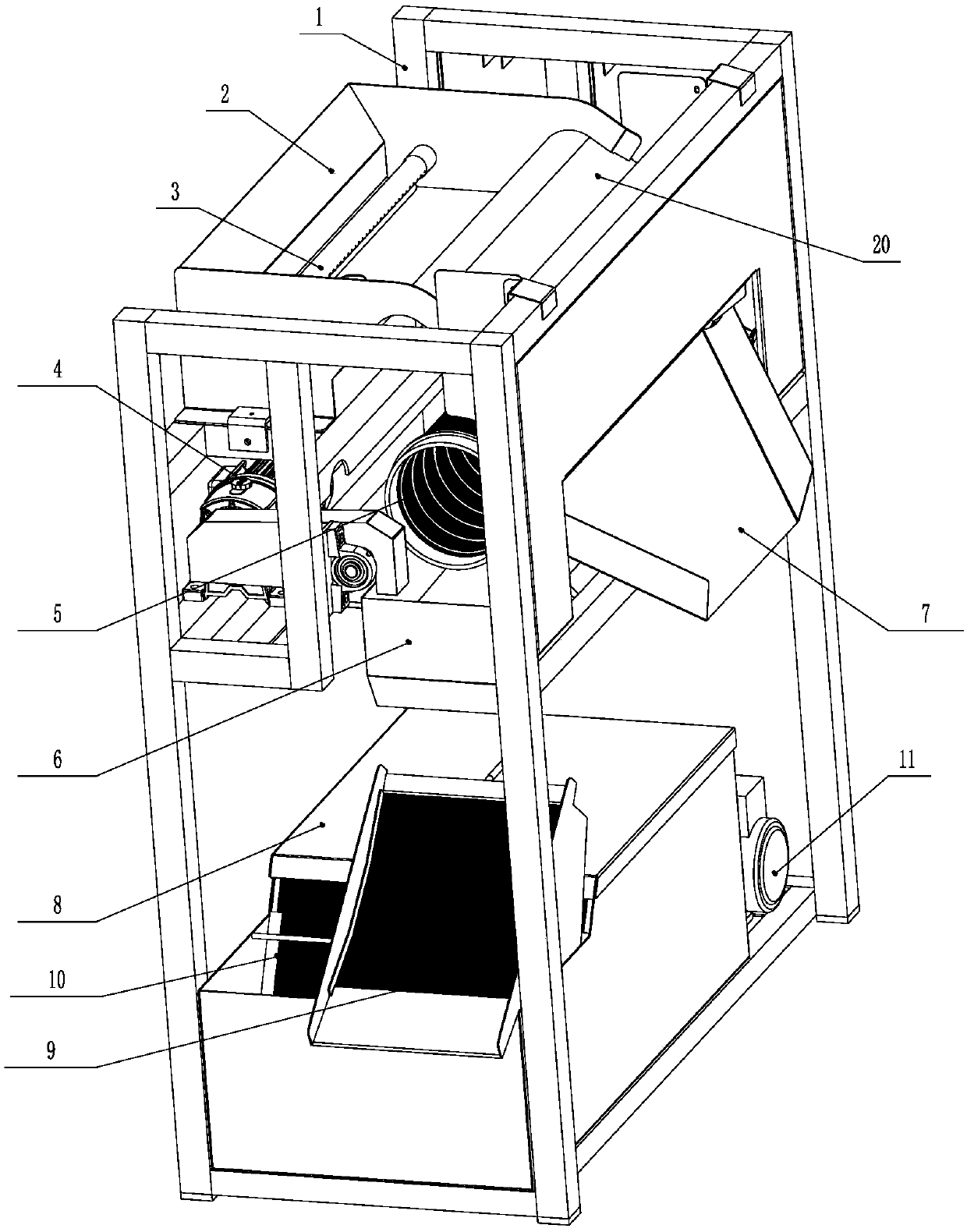

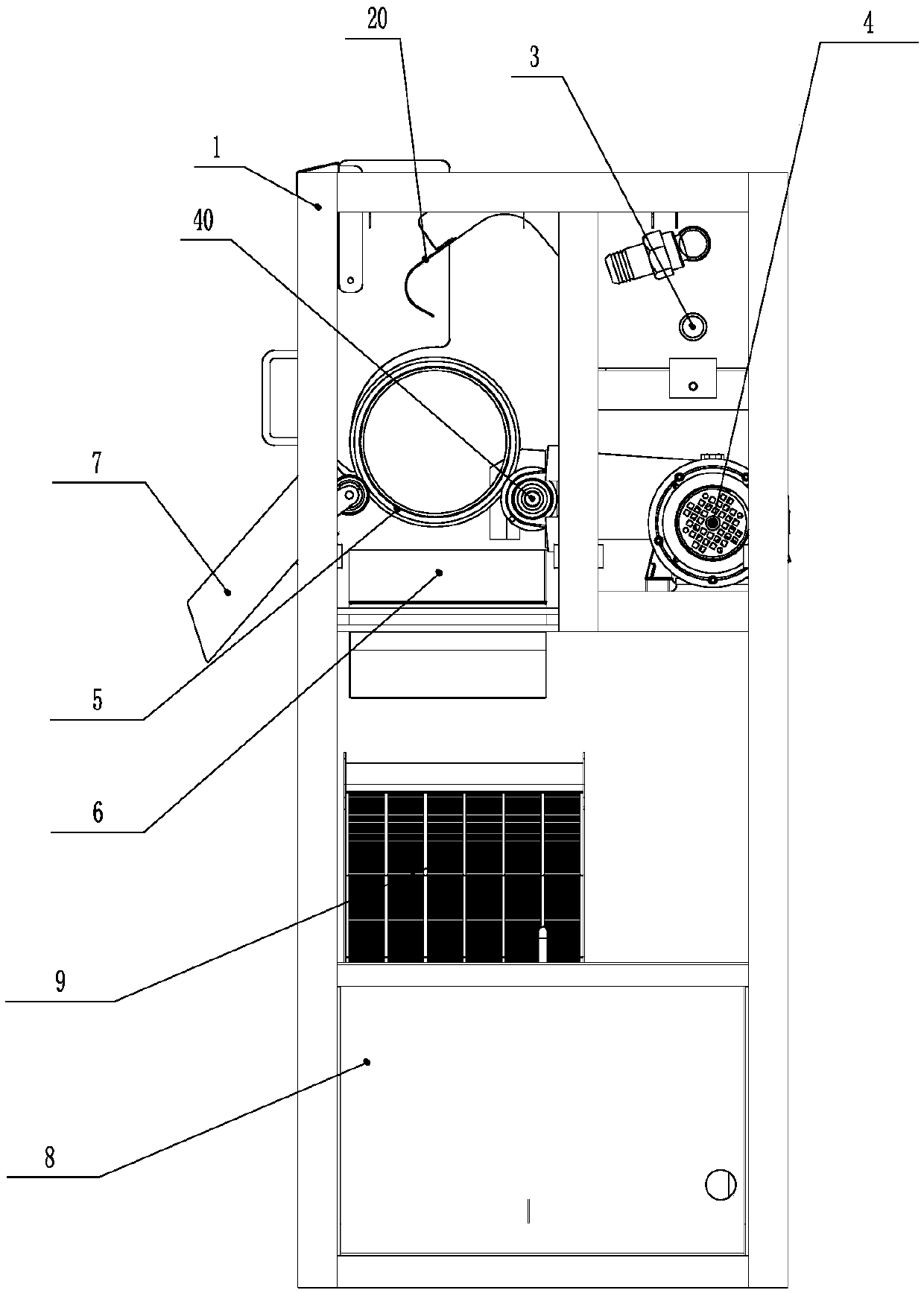

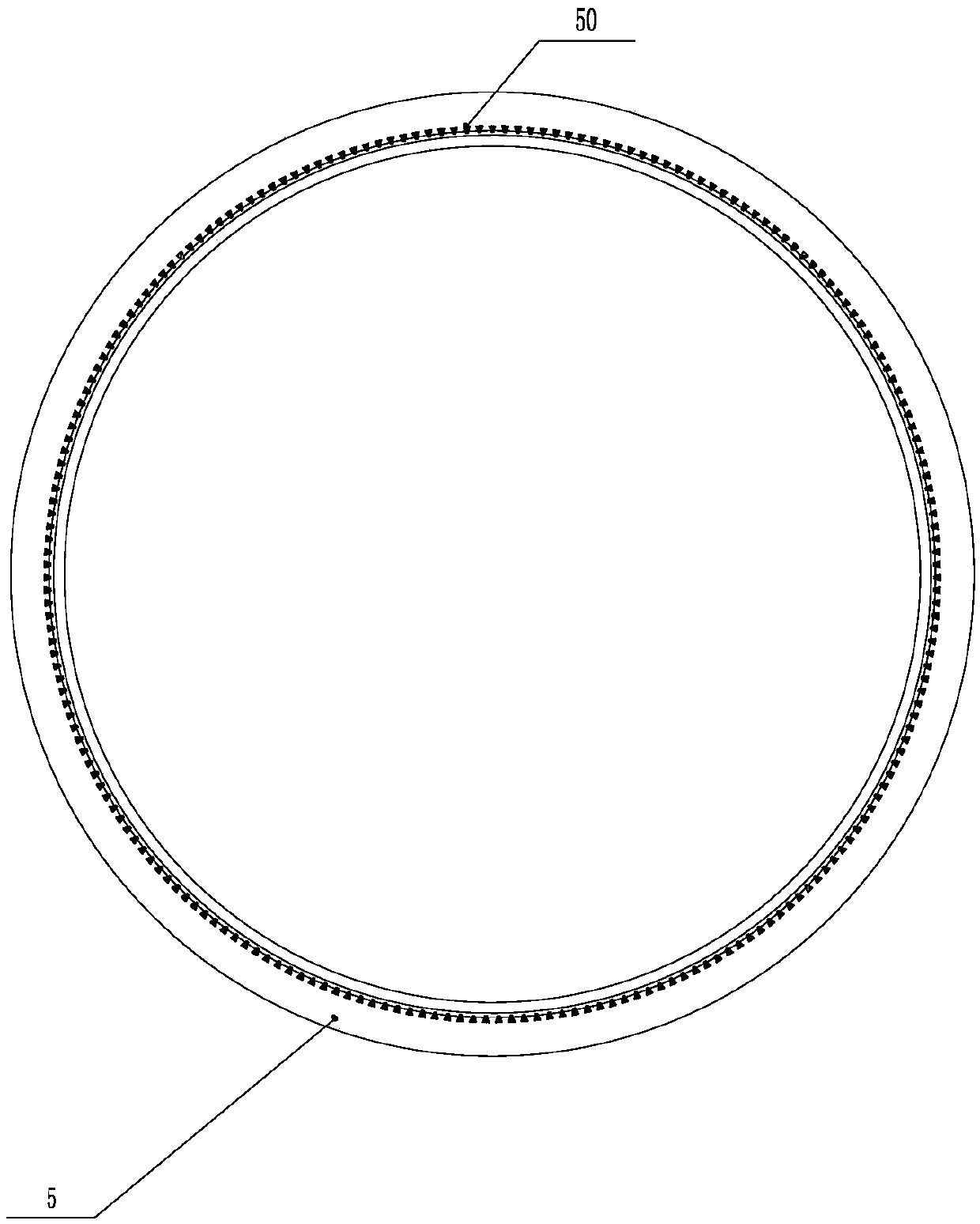

[0017] refer to Figure 1-3 , an industrial shrimp filter shell machine, including a frame 1, a water tank 2 is arranged on the top of the frame 1, a water inlet pipe 3 is arranged horizontally in the water tank 2, and a plurality of water inlet holes are arranged at intervals in front of the water inlet pipe 3. The side plate in front of the water inlet is an overflow plate 20 whose upper edge is lower than the other side plates. On the filter drum 5. Filter drum 5 front side lower position is provided with shelled shrimp guide groove 7, and this shelled shrimp guide groove 7 is connected with filter drum 5 by roller, prevents shelled shrimp from falling from the gap. Motor 4 is connected sprocket wheel 40 by chain, and sprocket wheel 40 drives filter drum 5 to rotate away from shelled shrimp guide groove 7 directions from its upper direction. The filter drum 5 is surrounded by a number of inverted trapezoidal slanted wedge strips at equal intervals, and is fixed by the dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com