Detector geometric correction phantom and correction method

A geometric correction and detector technology, applied in the field of radiation imaging, which can solve the problems of unrealistic performance of detector images, high inconsistency, and too large data, and achieve the effect of satisfying high-quality image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

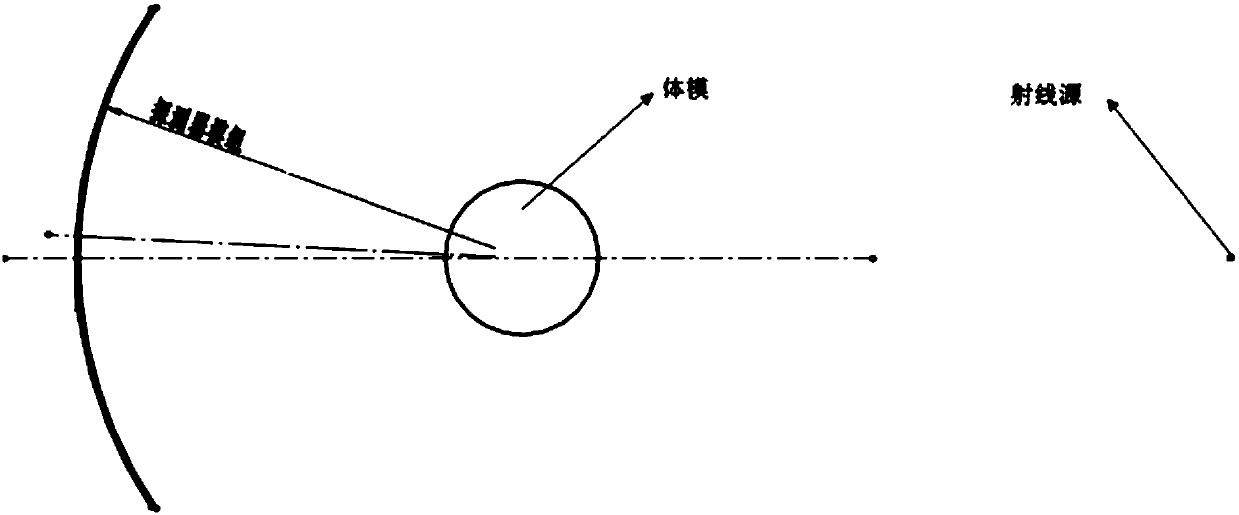

[0047] The technical content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

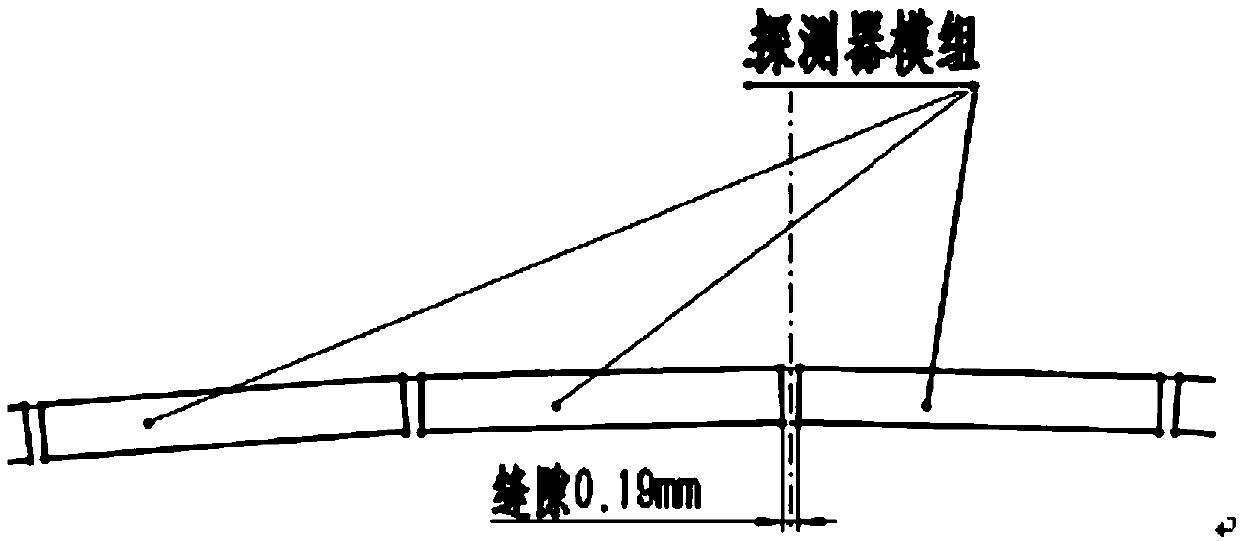

[0048] Such as Figure 5 and Figure 6 As shown, the detector geometric correction phantom provided by the present invention includes a geometric correction phantom substrate 1, and a circular hole array consisting of several rows of transverse circular holes and longitudinal circular holes of the same size is arranged on the geometric correction phantom substrate 1 2; where the spacing between adjacent circular holes is the same; and, as Figure 7 As shown, the range of the circular hole covers the entire X-ray receiving surface of the detector.

[0049] Such as Figure 6 As shown, the geometric correction phantom base plate 1 is a rectangular plate, and the rectangular plate is curved. The geometric correction phantom base plate 1 can be made of materials with high X-ray absorption capacity, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com