Application of magnetic elastic material to 4D printing

A magnetoelastic and 3D printing technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of difficult control, long time, and limitation of 4D intelligent printing technology, and achieve non-touch adjustment and rapid deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Add 5g of iron powder to 5g of Dow Corning SE1700, and mix evenly to form the magnetic ink to be printed.

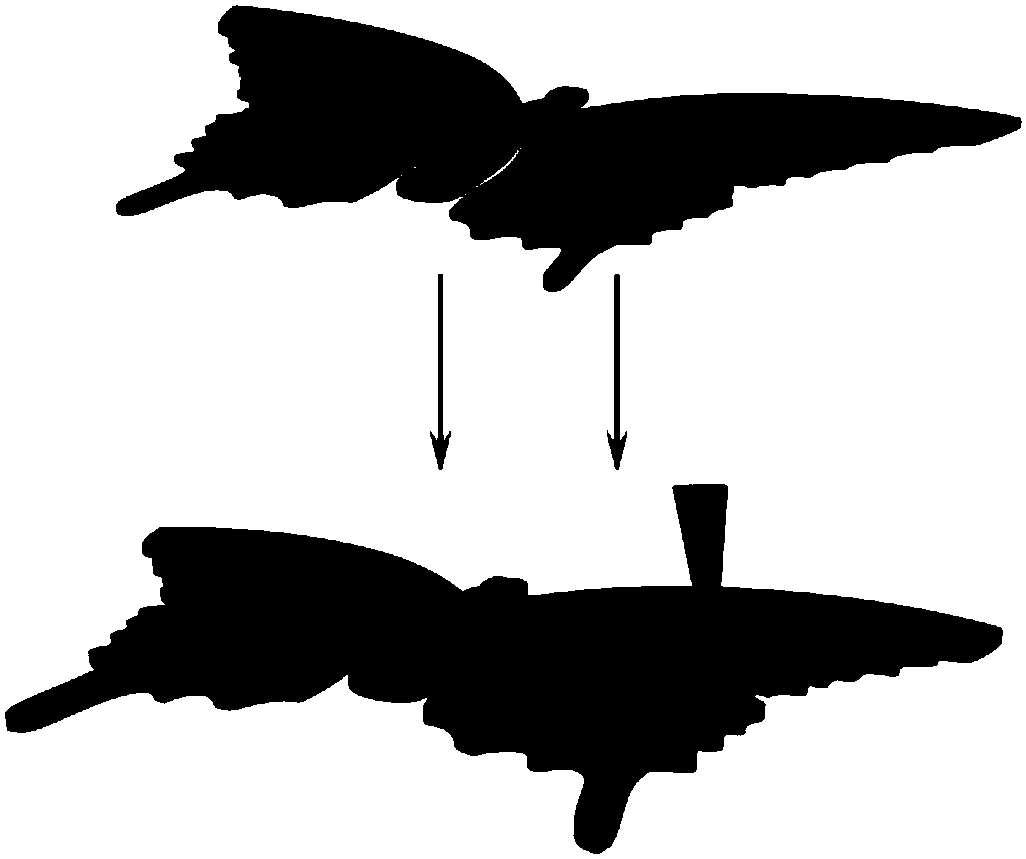

[0027] Step 2: Put the ink into the printer barrel, set the butterfly model, slice it, generate the printing path, and print according to the butterfly path, such as figure 1 shown.

[0028] Step 3: Heat and cure the printed butterfly at 100°C for 1 hour.

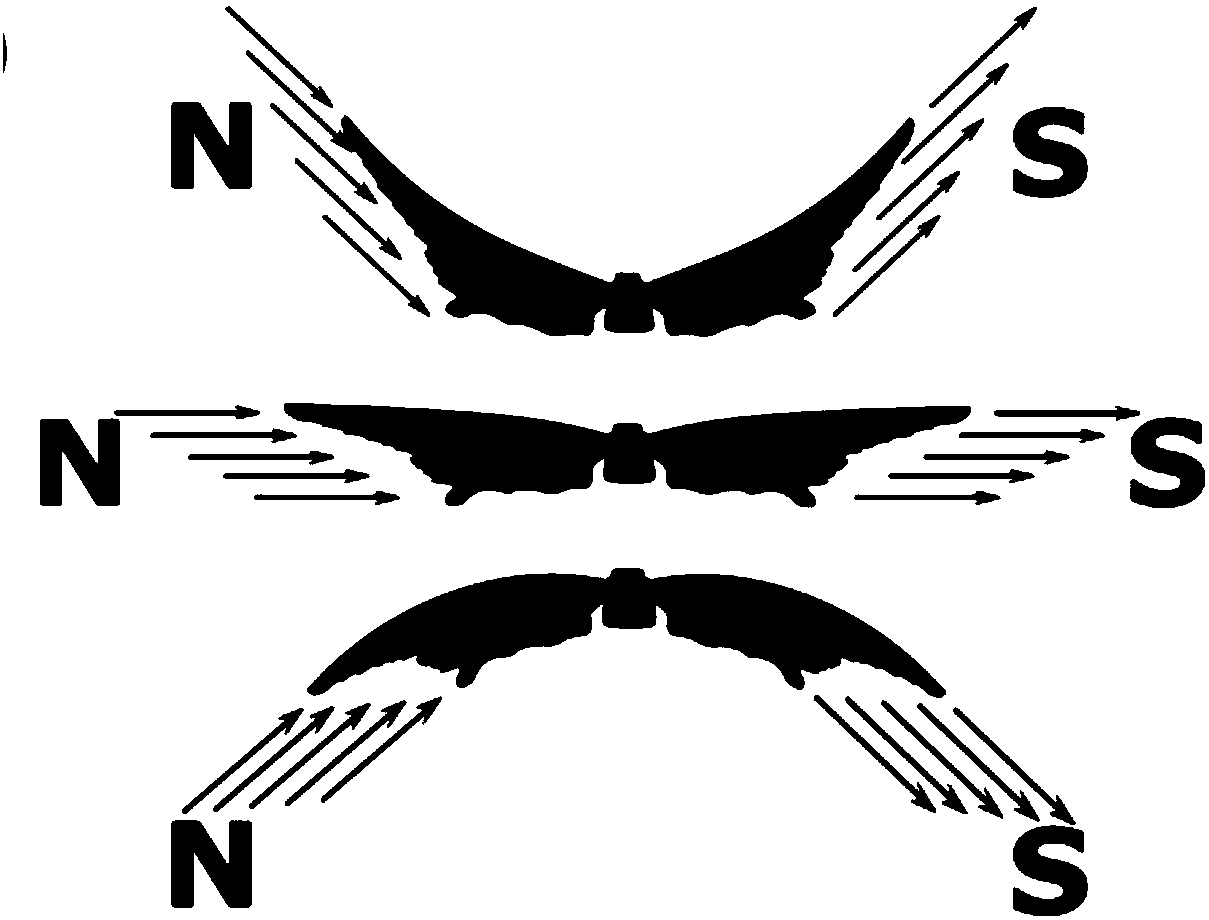

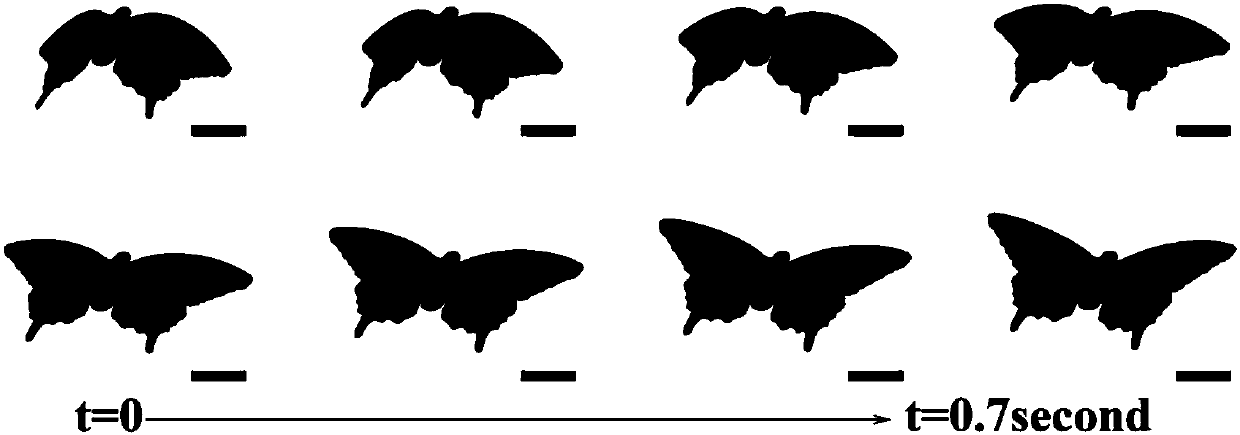

[0029] Step 4: Apply an externally changing magnetic field excitation to the heat-treated butterfly, such as figure 2 As shown, realize the movement of the butterfly in the fourth dimension, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com