Wood board automatic conveying and stacking device and control method thereof

An automatic conveying and plank technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems that the planks cannot be stacked flat, cannot be removed, and cannot continue to produce, achieving compact structure, ensuring uniformity, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

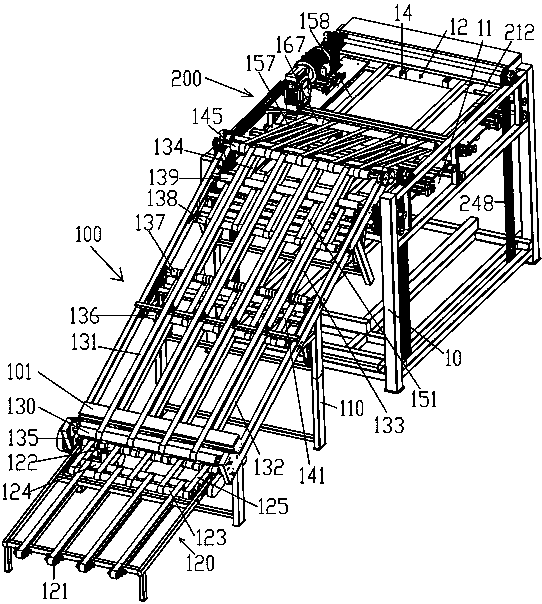

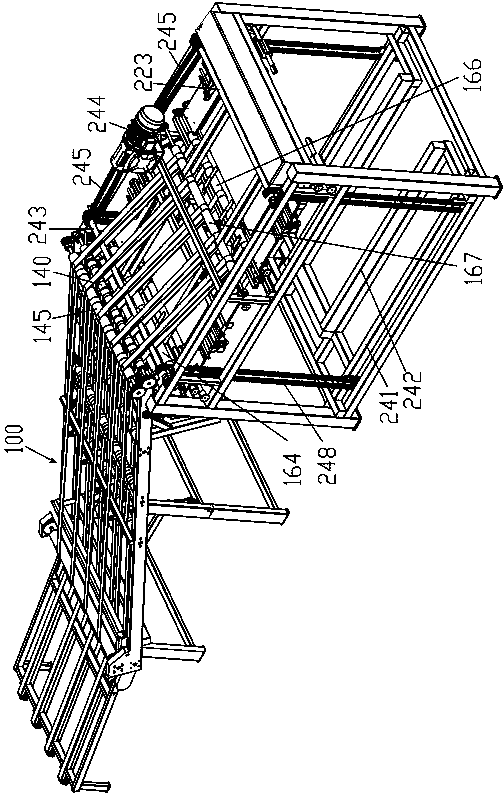

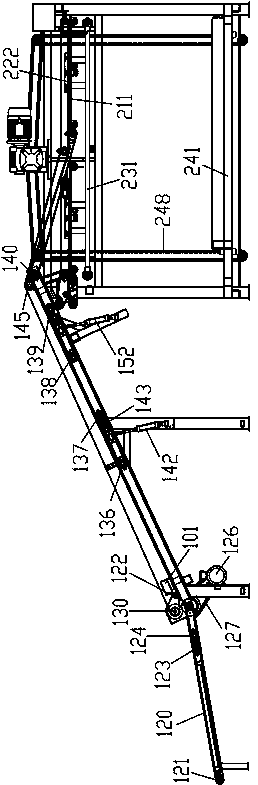

[0032] refer to Figure 1 to Figure 8

[0033] An automatic conveying and stacking device for wooden boards, comprising a frame 10, on which a first discharging station 11 and a second discharging station 12 are horizontally arranged, and a pinch feeding station for inputting wooden boards is provided on the front side of the frame Device 100, the middle part of the pinching device is provided with a kicking mechanism for rejecting unqualified planks, and the output end of the pinching device is provided with a plank diverting mechanism for leading the planks to the first and second discharge stations, The first and second discharge stations are provided with a plank stacking and finishing device 200 for sortin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com