Wear-resistant and anti-friction zirconia ceramic coating on metal surface and preparation method thereof

A zirconia ceramic and metal surface technology, applied in metal material coating process, coating, liquid chemical plating and other directions, can solve the problems of increasing the wear resistance and friction reduction performance of zirconia ceramic coating, and achieve good friction reduction effect. , Simple operation, long wear life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

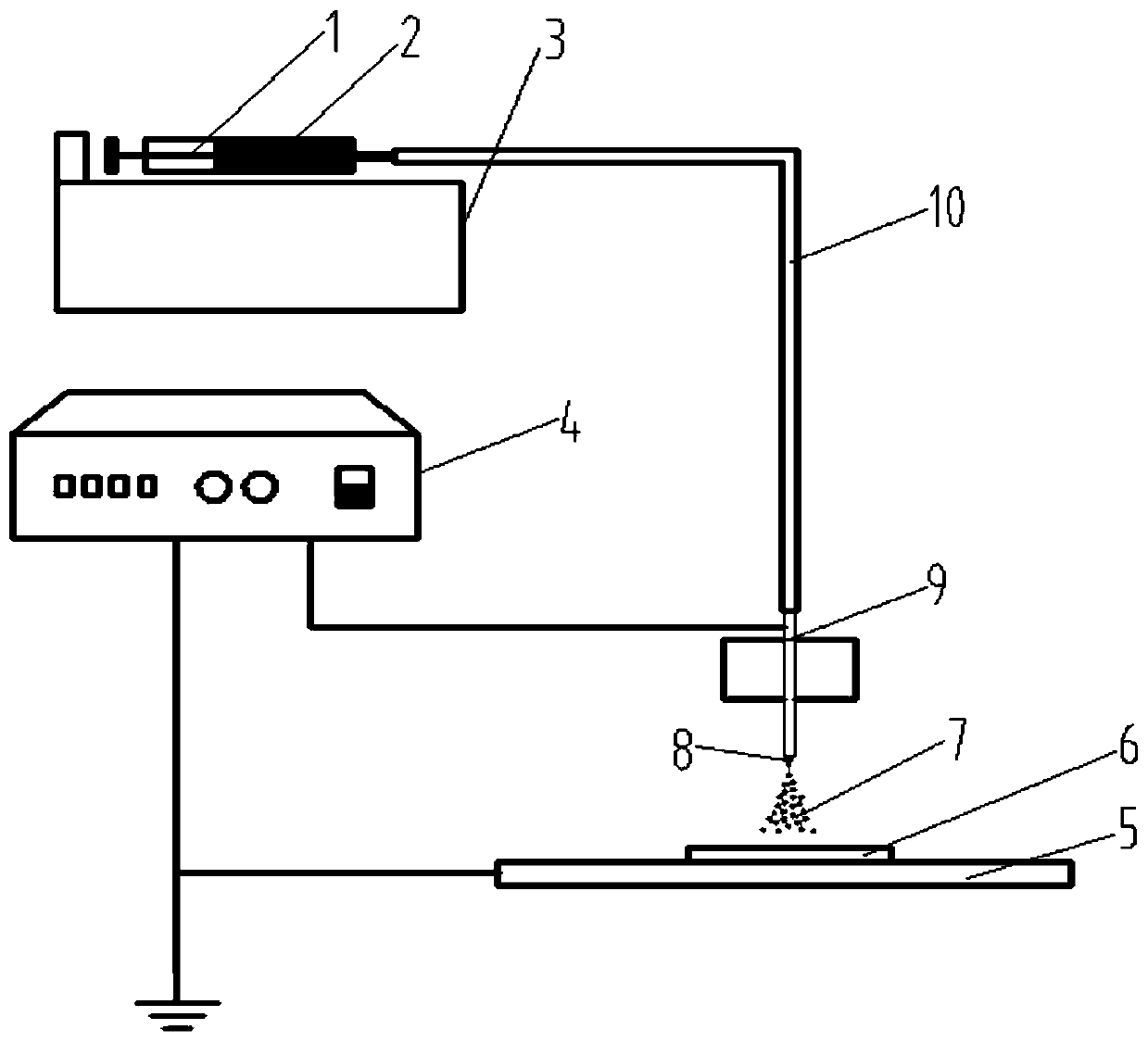

Method used

Image

Examples

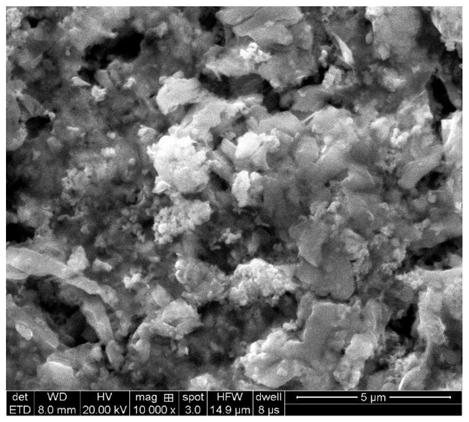

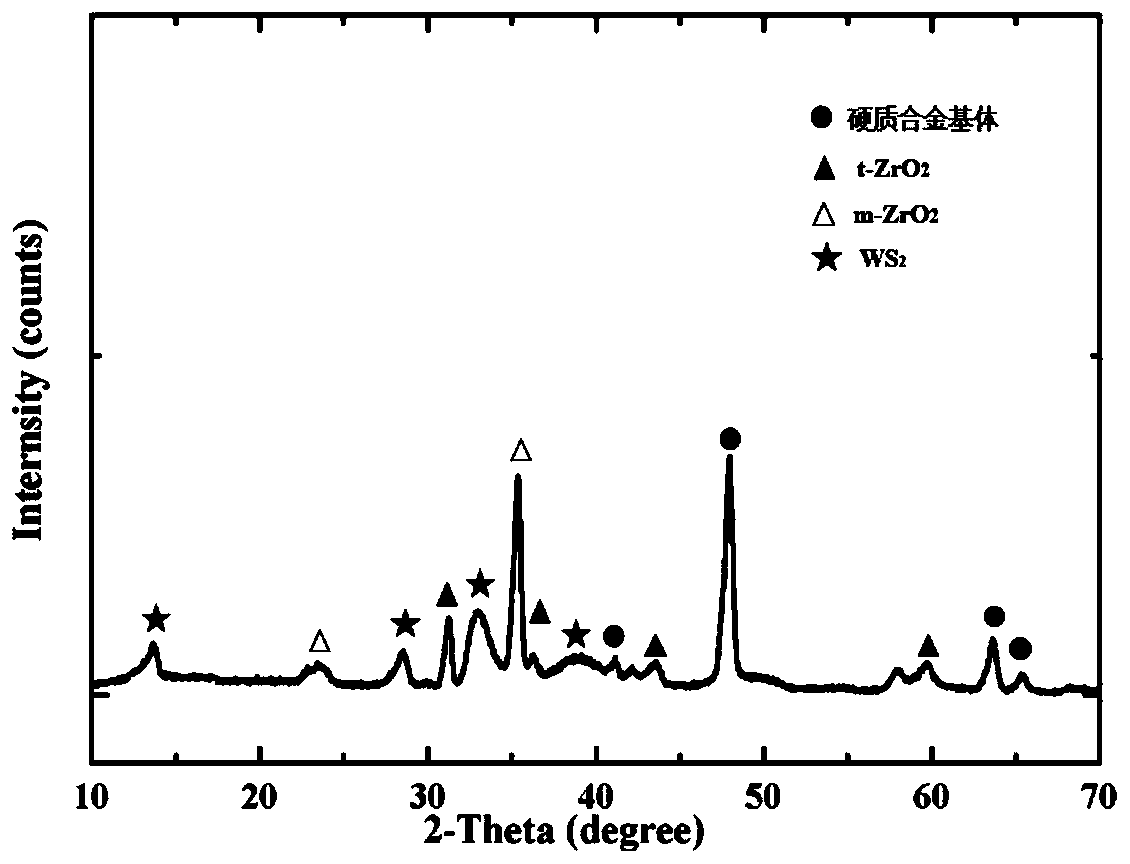

Embodiment 1

[0041] A metal surface wear-resisting anti-friction ZrO 2 Ceramic coating and method for its preparation. The metal material is cemented carbide sheet (the main components are WC, TiC, Co), and the surface of the cemented carbide is coated with ZrO 2 ceramic coating. where ZrO 2 The preparation method of ceramic coating is: prepare ZrO 2 Composite slurry, using this composite slurry to form micron-scale fine jets and nano-scale droplet groups under the action of electric field force, and deposit ZrO layer by layer on the cemented carbide substrate 2 ceramic coating. The concrete steps of its preparation method are:

[0042] 1. Metal substrate pretreatment

[0043] The surface of the cemented carbide sheet (three-dimensional size: 20 mm × 20 mm × 10 mm) was polished to a mirror surface, and ultrasonically cleaned in acetone and absolute ethanol solutions for 20 min, respectively.

[0044] 2. Slurry preparation

[0045] Mix and stir 4.1g zirconium n-propoxide, 15.7g abso...

Embodiment 2

[0051] A metal surface wear-resisting anti-friction ZrO 2 Ceramic coating and method for its preparation. The metal material is 316L stainless steel sheet, and the surface of the stainless steel is coated with ZrO 2 ceramic coating. where ZrO 2 The preparation method of ceramic coating is: prepare ZrO 2 Composite slurry, using this composite slurry to form micron-scale fine jets and nano-scale droplet groups under the action of electric field force, deposit ZrO layer by layer on the stainless steel substrate 2 ceramic coating. The concrete steps of its preparation method are:

[0052] 1. Metal substrate pretreatment

[0053] The 316L stainless steel sheet (three-dimensional size: 20mm×20mm×10mm) was polished to a mirror surface, and ultrasonically cleaned in acetone and absolute ethanol solutions for 20 min, respectively.

[0054] 2. Slurry preparation

[0055] Mix and stir 4.1g zirconium n-propoxide, 15.7g absolute ethanol and 1g glacial acetic acid for 2h to obtain Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com