Structure of prefabricated road shoulder and construction method thereof

A construction method and technology of road shoulders, applied to roads, roads, side ditches/curbs, etc., can solve problems such as long construction time and solidification time, poor structural stability, and pollution of the surrounding environment, so as to save cleaning links and improve anti-corrosion Inclinability and effects of high crash resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

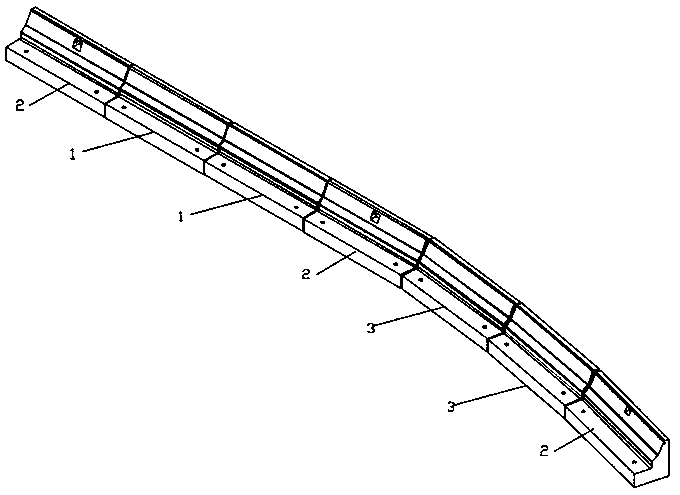

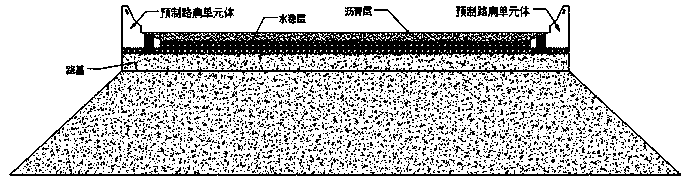

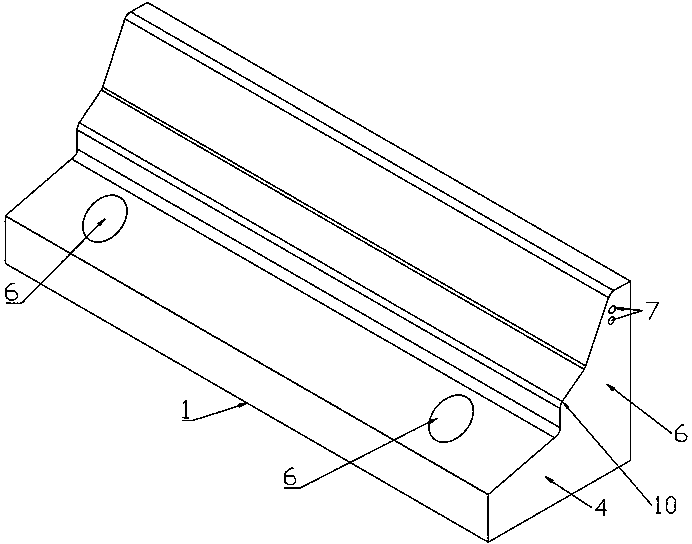

[0026] Example 1. If figure 1 and 2 As shown, a prefabricated shoulder structure is composed of more than one prefabricated shoulder unit. The prefabricated shoulder unit is divided into three types: prefabricated shoulder A1, prefabricated shoulder B2 and prefabricated shoulder C3. Prefabricated shoulder A1, prefabricated shoulder Both B2 and prefabricated shoulder C3 include a base 4 and a vertical wall 5, the upper surface of the base 4 is provided with a chamfer that is inclined downward, and a reinforced connection is provided at a right angle between the base 4 and the vertical wall 5 plate 10, the base 4, the vertical wall 5 and the reinforced connecting plate 10 are integrally poured with concrete, and more than one vertical through hole 6 is provided on the base 4, and the vertical wall of the prefabricated shoulder A1 The surface 5 is provided with more than one threading hole 7 through the left and right ends for the steel strand to pass through; the vertical wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com