Cantilever scaffold

A technology of cantilevered scaffolding and scaffolding, which is applied in the field of cantilevered scaffolding, can solve the problems of increasing construction cost, delaying construction progress, and serious leakage hidden dangers, and achieves the effects of preventing grout leakage, improving construction quality, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

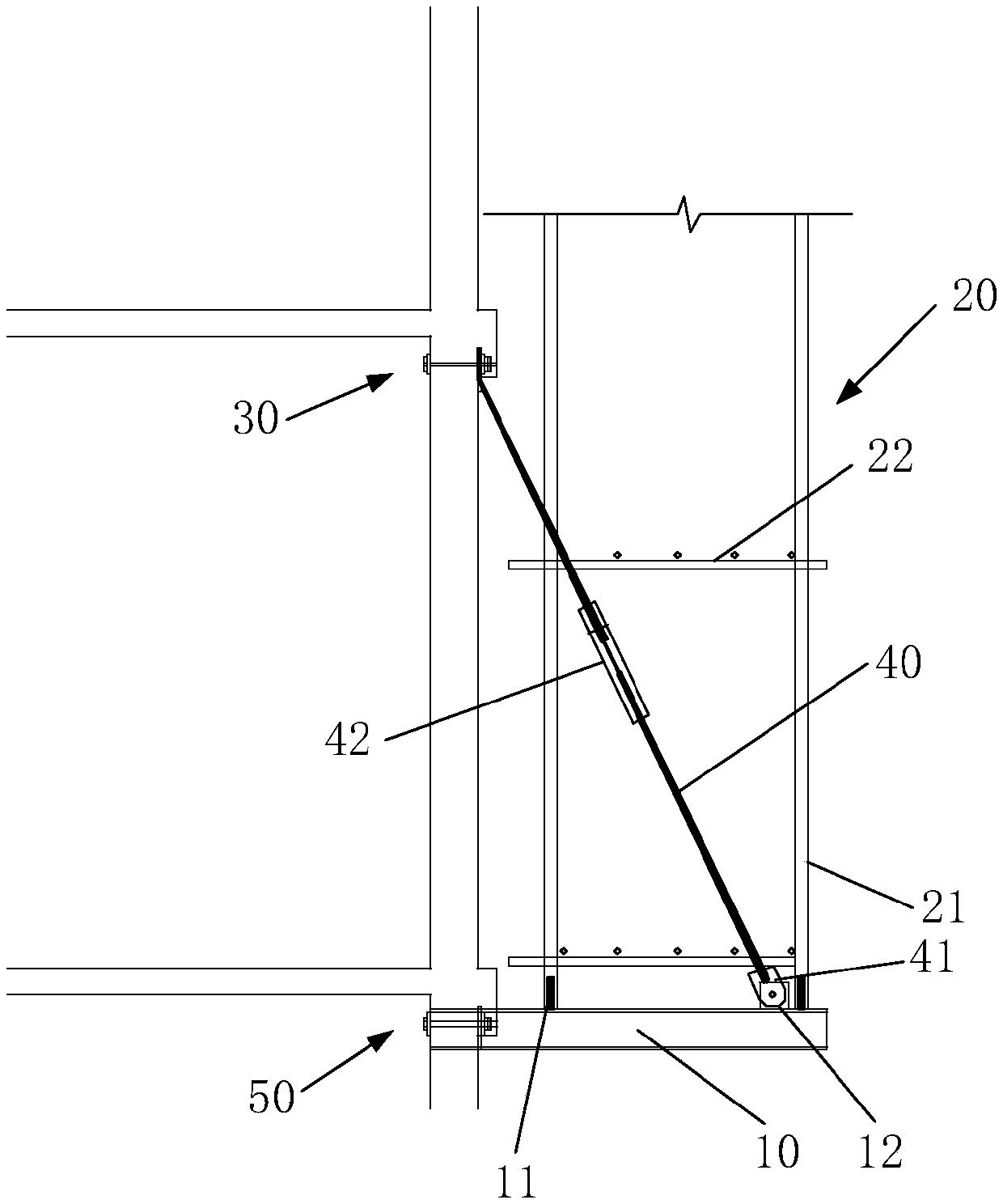

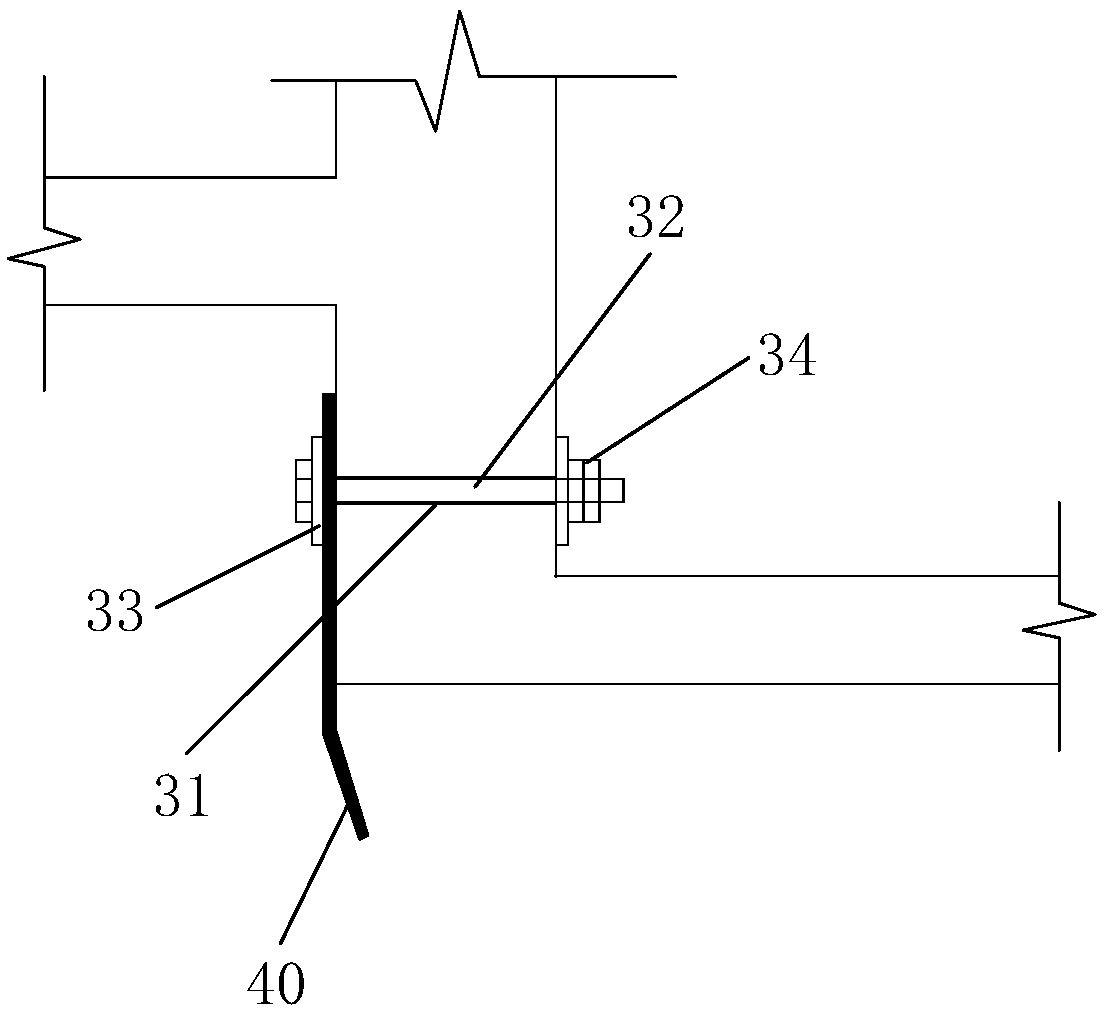

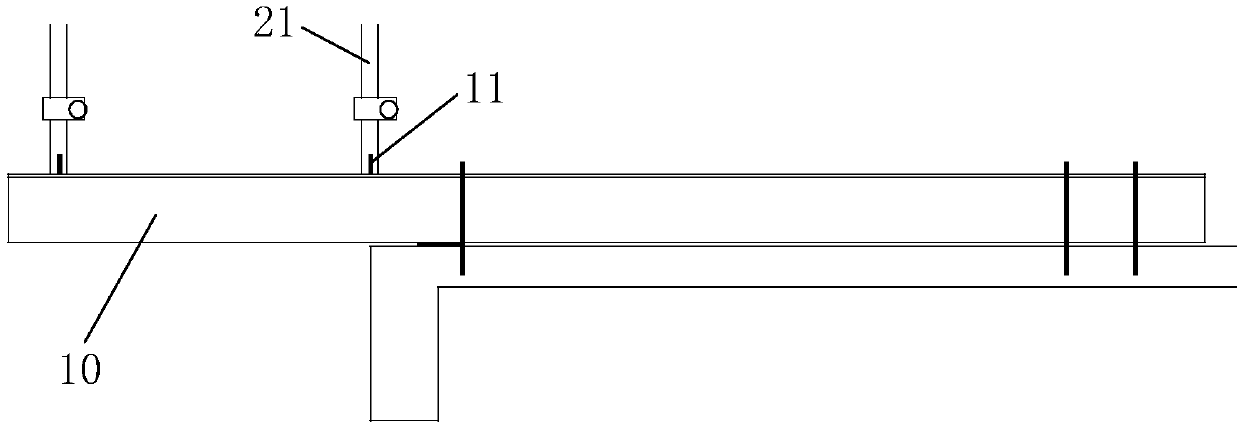

[0026] For the cantilevered scaffold provided by the present invention, please refer to Figure 1 to Figure 3 , comprising a cantilevered steel 10 (No. 18 I-beam), a scaffold body 20, a first tie anchor 30 and a steel wire rope 40, the cantilevered steel 10 is fixed on the substructure floor and extends outward in the horizontal direction, The scaffold body 20 is fixedly installed on the extension section of the cantilevered steel 10, the first tie anchor 30 is fixed in the reinforced concrete structure, and the two ends of the steel wire rope 40 are connected with the first tie respectively. The anchorage 30 is fixedly connected with the cantilever steel 10 . The present invention uses the first tie anchor 30 and the cantilevered steel 10 to connect the two ends of the steel wire rope 40 to realize a pull-up cantilevered scaffold, which can effectively prevent the mold explosion phenomenon of the connection part of the outer wall panel during concrete pouring, and The operat...

Embodiment 2

[0033] Please focus on reference Figure 4 The difference between this embodiment and Embodiment 1 is that the number of the steel wire ropes 40 is two, and one end of the two steel wire ropes 40 is fixed on the first tie anchor 30, and the other ends are respectively fixed on the On the fixing bases 12 corresponding to the two steel bar heads 11 respectively, in other words, in the present invention, two tie knots are arranged at the position where the tie strength needs to be increased (such as the window position).

[0034] Preferably, please continue to refer to Figure 4 , the angle between the steel wire rope 40 on the inside and the vertical surface is 19°~35°; the angle between the steel wire rope 40 on the outside and the vertical surface is 19°~45°. The angle between the steel wire rope 40 and the vertical plane is greater than the angle between the inside steel wire rope 40 and the vertical plane.

[0035] In summary, the cantilevered scaffold provided by the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com