Buffer base for die casting machine

A technology of die-casting machine and buffer device, which is applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve the problems that the die-casting machine base cannot be raised and lowered, the service life of the die-casting machine is affected, and the buffering effect of the base is not obvious. Pressure, easy operation, the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

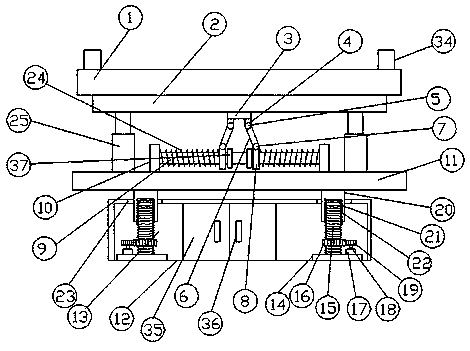

[0027] see figure 1 , a buffer base for a die-casting machine according to an embodiment of the present invention, comprising a top plate 1, a support plate 2 is fixed under the top plate 1, a fixed plate 3 is fixed under the support plate 2, and the fixed plate 3 Connecting blocks 4 are fixed at both ends, and a first rotating shaft 5 is arranged on the connecting block 4, and a connecting rod 6 is connected to the first rotating shaft 5, and a second rotating shaft 7 is provided on the other end of the connecting rod 6. , the second rotating shaft 7 is movably connected with a slider 8, the slider 8 is provided with a sliding rod 9, the connecting ends of the sliding rod 9 are provided with first springs 24, and the two ends of the sliding rod 9 All are provided with connecting plate 10, described connecting plate 10 below is provided with base plate 11, and described connecting plate 10 is fixed on described base plate 11, and described base plate 11 below is provided with ...

Embodiment 2

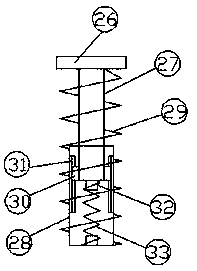

[0030] Such as Figure 1-2As shown, both ends of the top plate 1 are provided with limiting plates 34; both ends of the top plate 1 are provided with limiting plates 34, which can help the die-casting machine to be fixed on the top plate 1 and increase its stability. A buffer device 25 is symmetrically provided between the support plate 2 and the base plate 11; a buffer device 25 is symmetrically provided between the support plate 2 and the base plate 11, which can help the first spring 24 to play a buffering role. , reducing the pressure on the first spring 24 can effectively support the die-casting machine. The buffer device 25 includes a horizontal plate 26, a second support rod 27 is arranged below the horizontal plate 26, and a third support rod 28 is provided outside the second support rod 27, and the second support rod 27 and the The third support rod 28 is covered with a second spring 29, and one end of the second support rod 27 located in the third support rod 28 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com