An On-Line Monitoring Device for Flange Leakage Based on Ultrasonic Sounder

A monitoring device and sound generator technology, which can be used in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as use conditions and application scope limitations, and achieve cost reduction, processing cost savings, and identification accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the explanatory text.

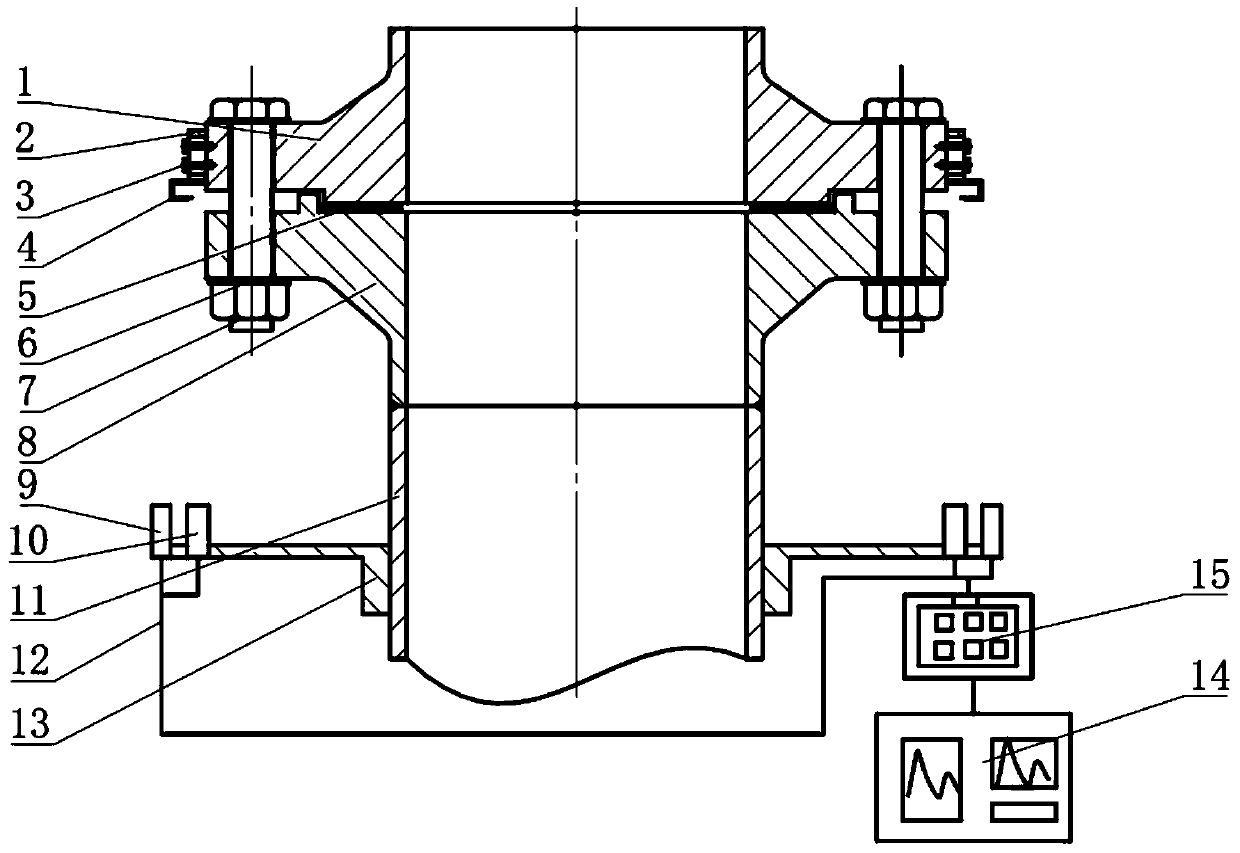

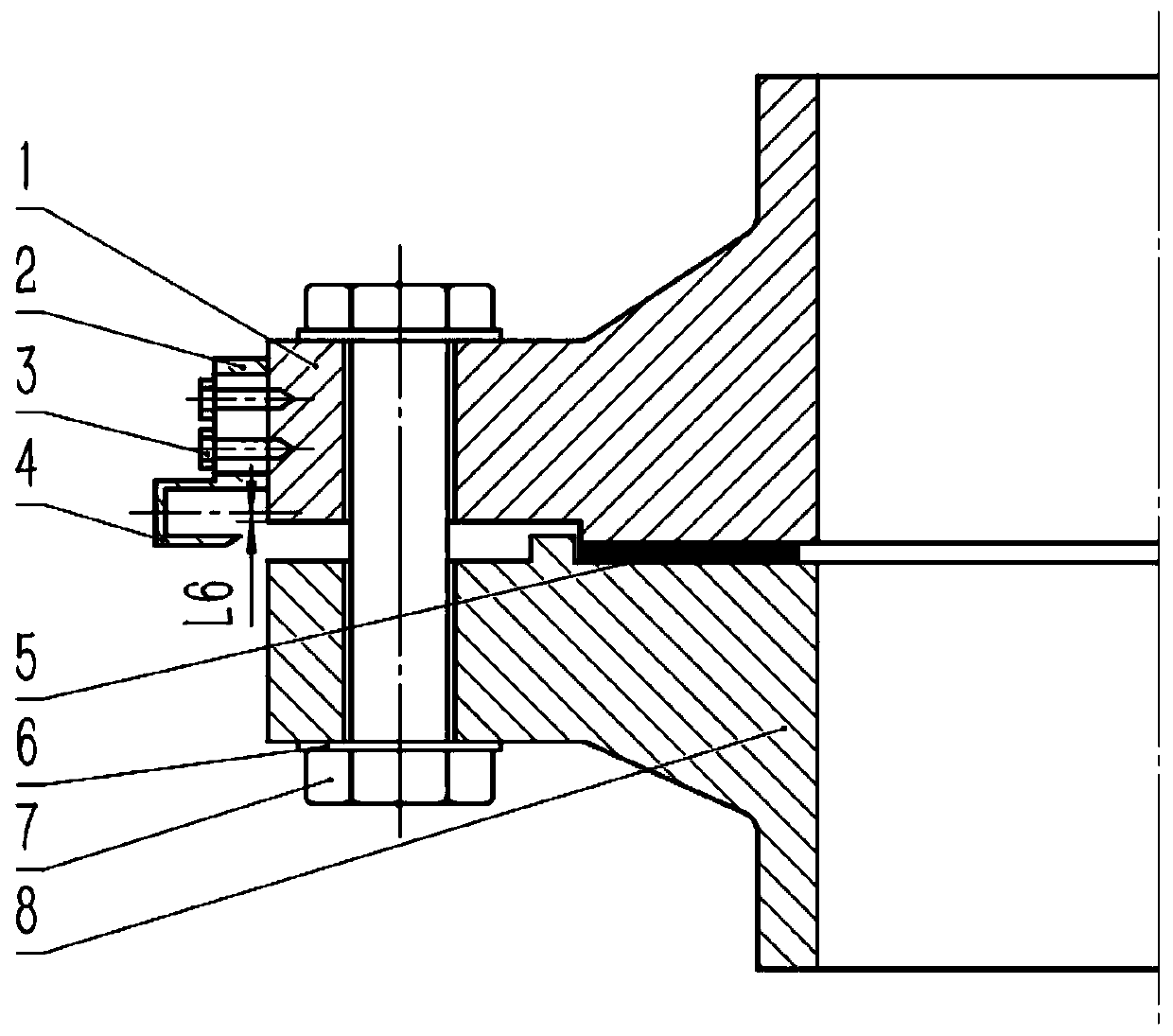

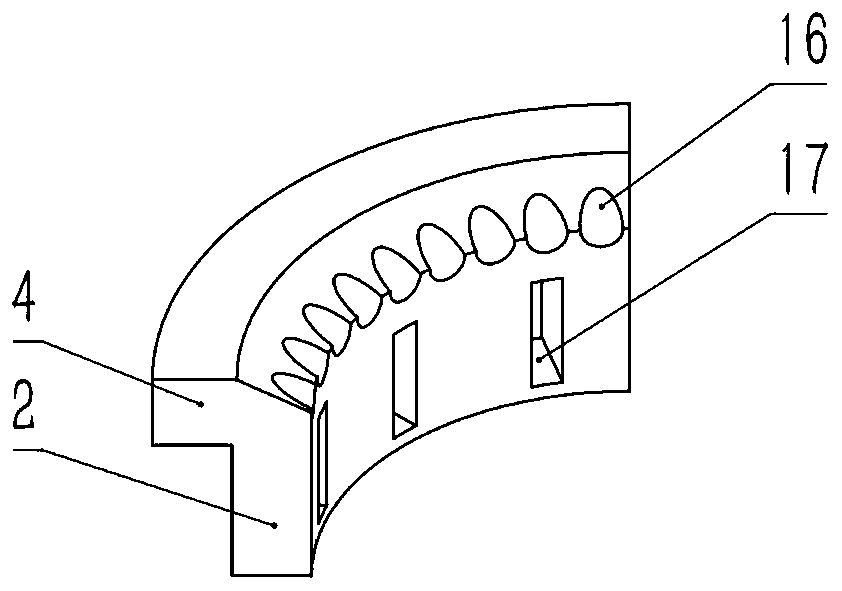

[0044] Such as Figure 1-8 As shown, the present invention provides a flange leakage online monitoring device based on an ultrasonic sounder, which is mainly composed of four parts: a flange joint part, an ultrasonic sounder part, a DSP signal acquisition and processing module, and a remote monitoring device. The flange is the main equipment to be monitored. The ultrasonic sounder is used to generate ultrasonic signals of a specific frequency. The DSP ultrasonic signal acquisition and processing module analyzes and processes the ultrasonic signals, and connects with the remote monitoring equipment through the communication module to realize remote monitoring.

[0045] The flange joint is installed on the pipeline, and the flange joint includes the flange upper end cover ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Radial height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com