Support fixture and falling ball test method

A ball drop test and fixture technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of uncertainty in test results, unreliable ball drop experiments on 3D glass cover plates, and achieve deterministic and improved strength test results. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

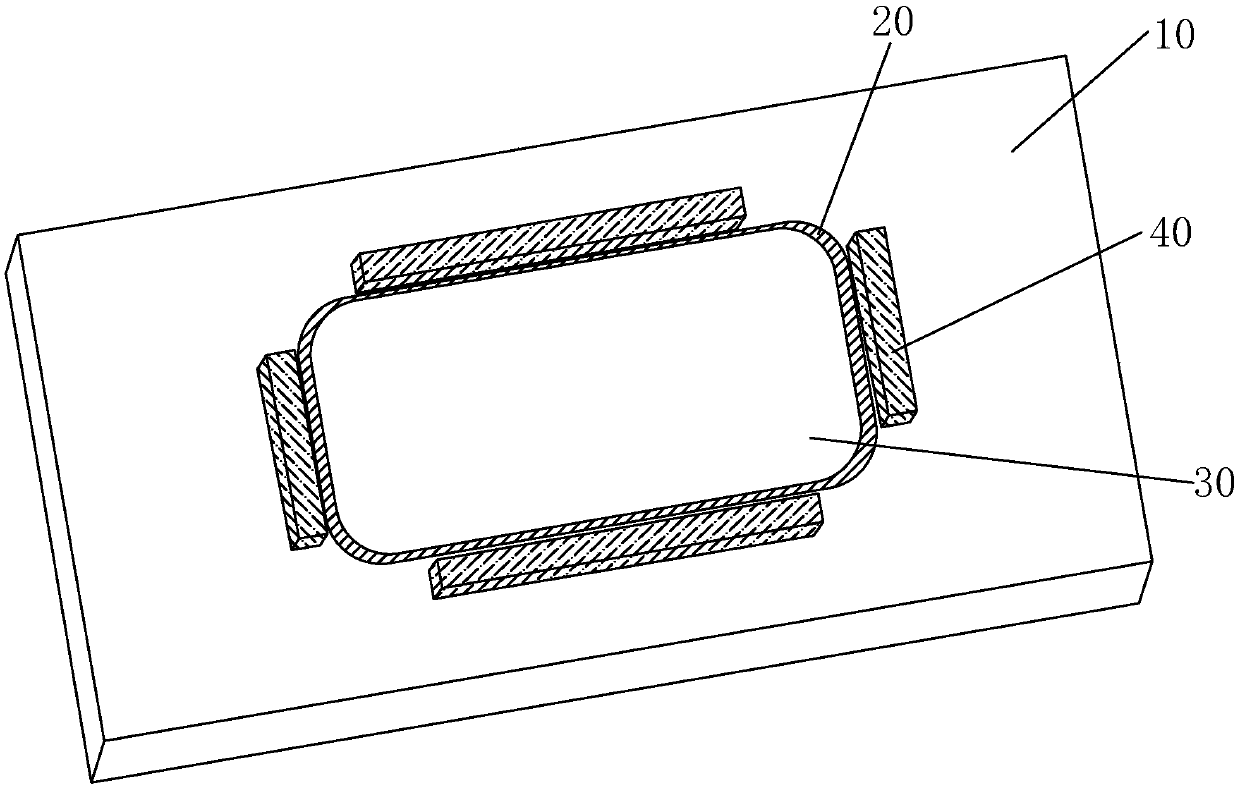

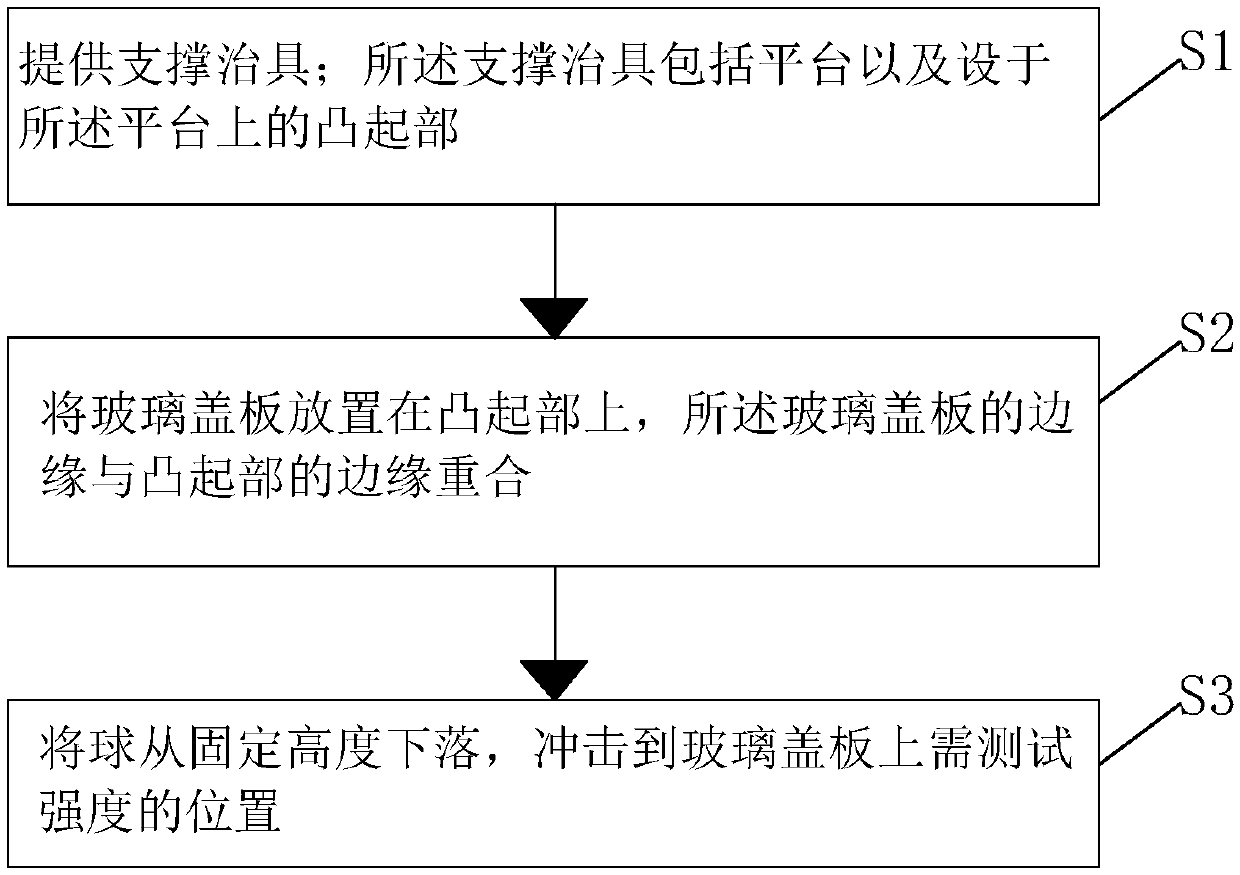

[0028] see figure 1 , the present invention provides a supporting jig for a ball drop test, comprising: a platform 10 and a raised portion 20 provided on the platform 10;

[0029] The raised portion 20 is used to place a glass cover, and the edge of the glass cover coincides with the edge of the raised portion 20 .

[0030] It should be noted that when the glass cover is subjected to a ball drop test, the glass cover is placed on the raised portion 20 of the supporting jig, and the edge of the glass cover coincides with the edge of the raised portion 20, that is, the glass cover It can be placed on the support jig stably. When the ball falls from a fixed height and hits the position on the glass cover where the strength needs to be tested, si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com