Submersible motor

A technology for submersible motors and rotating shafts, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of reduced service life and impact on the service life of submersible motors, and achieve the effects of improving sealing effects, good sand control effects, and reducing possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

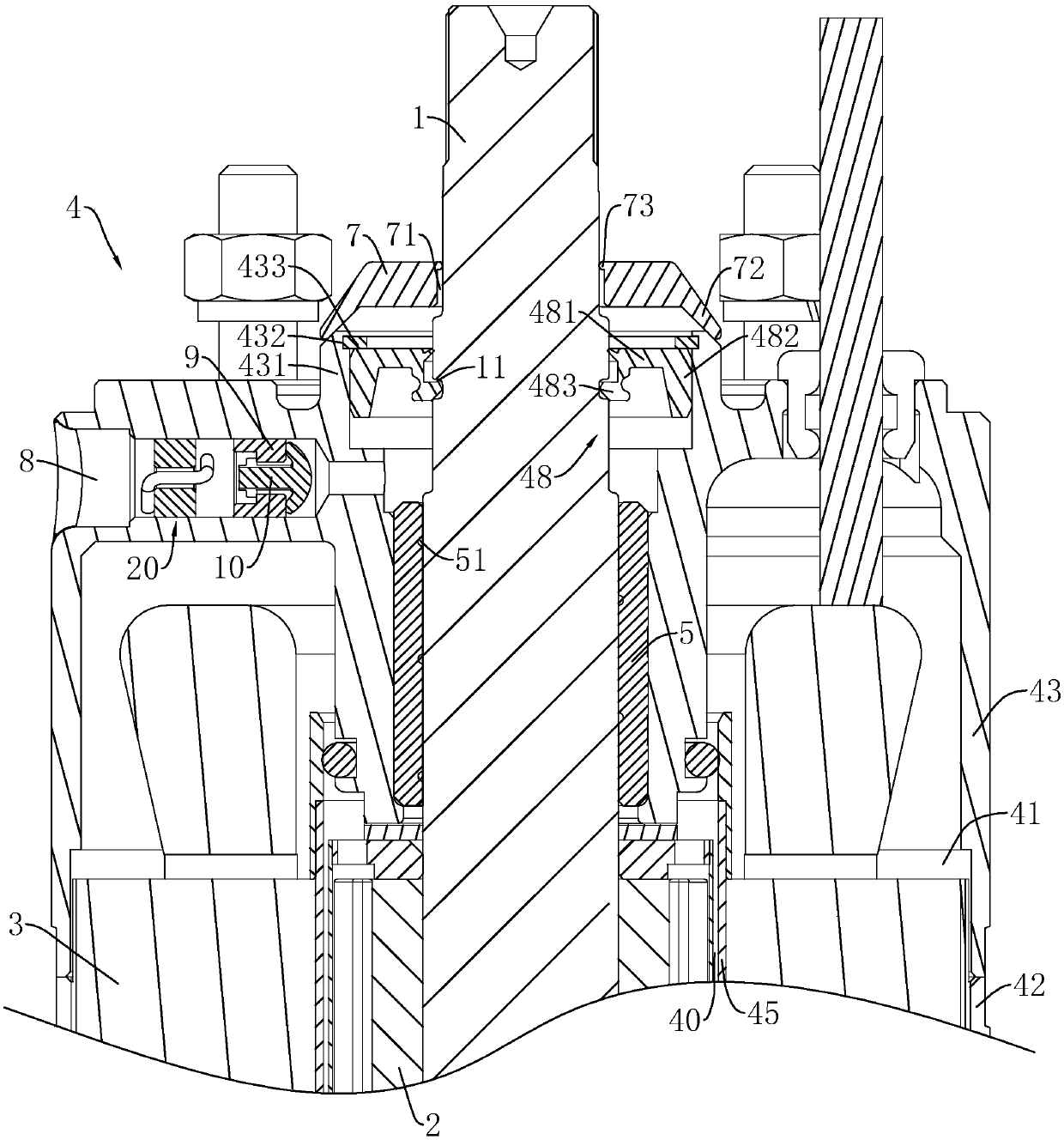

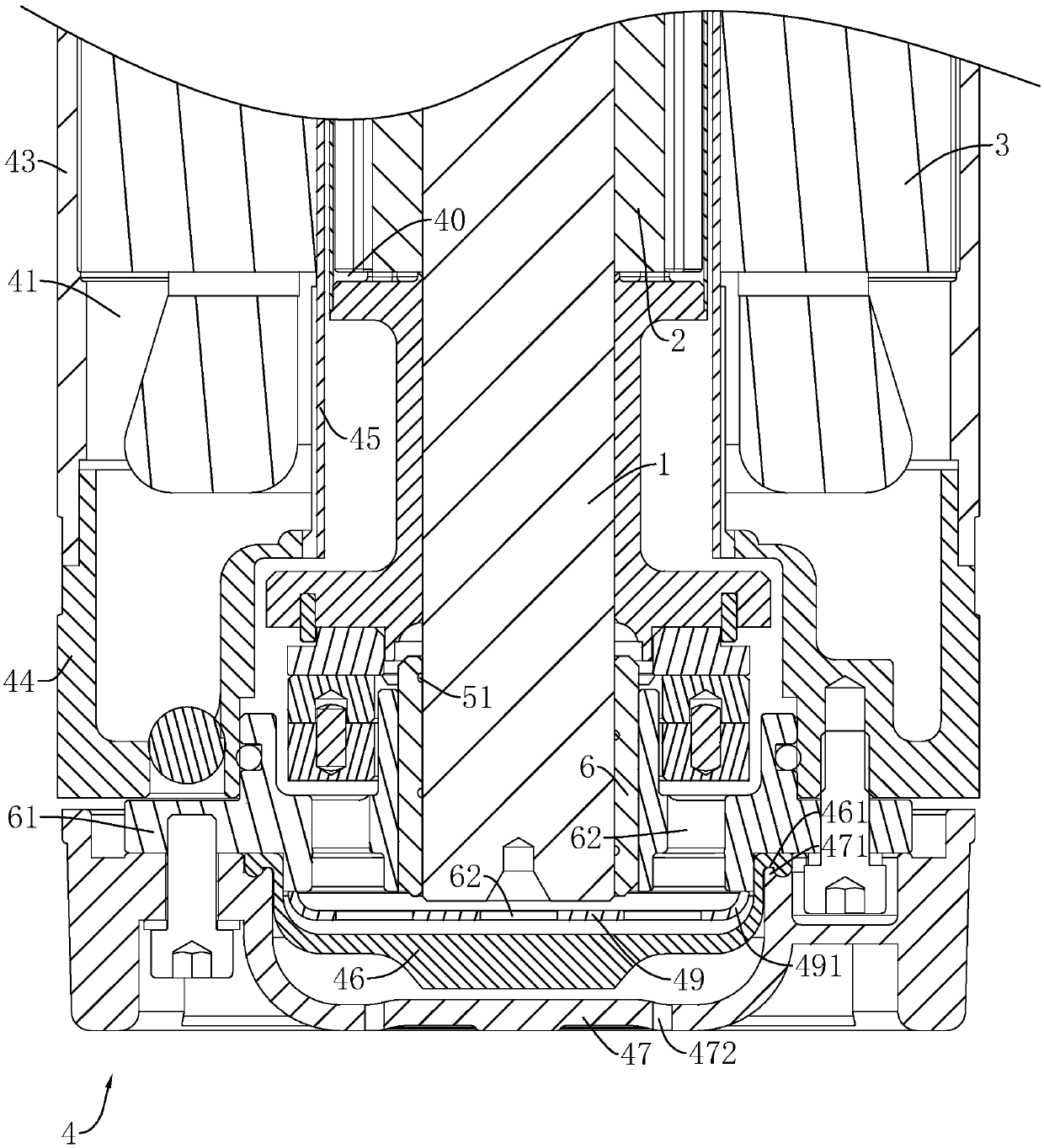

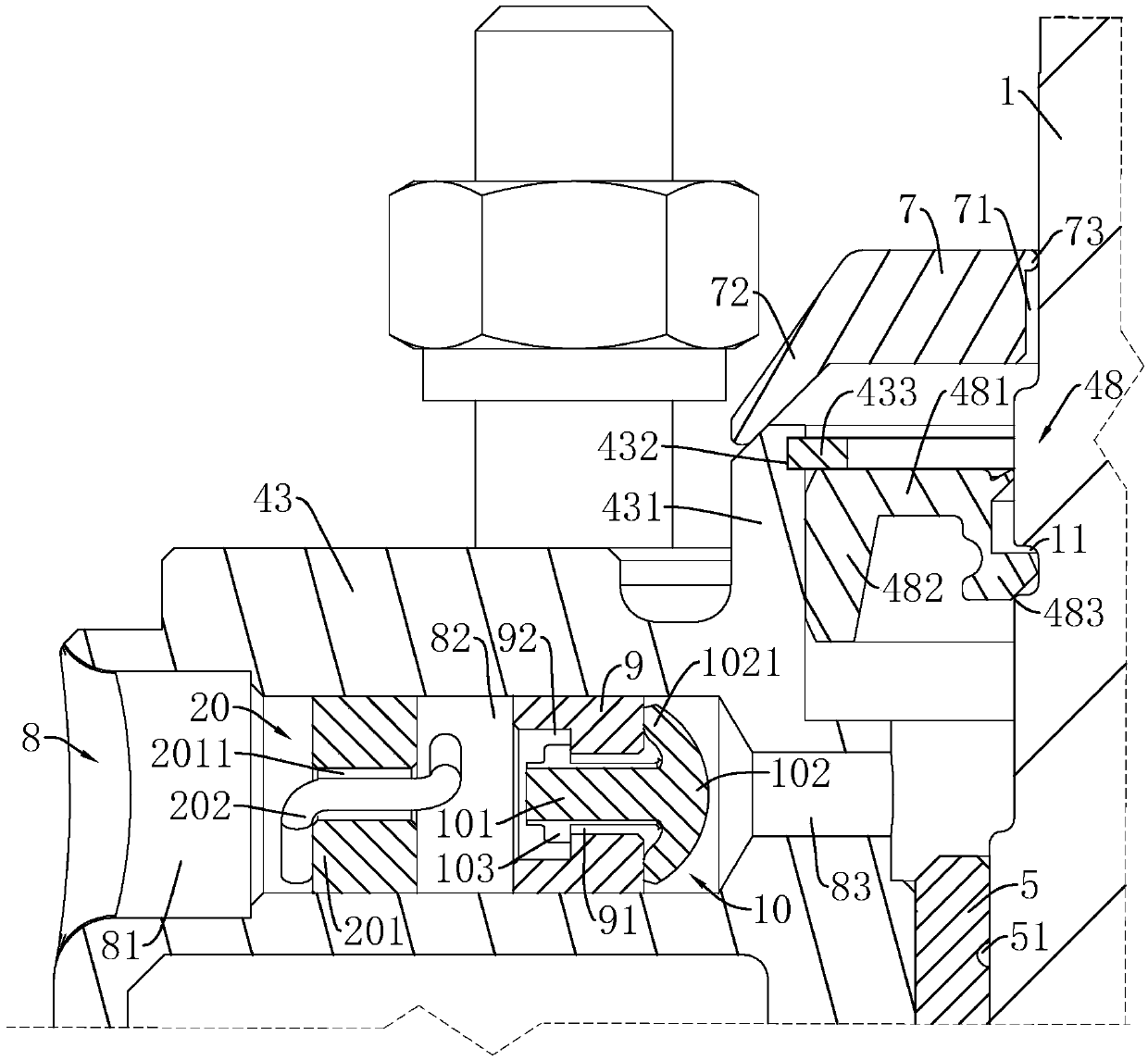

[0038] Embodiment: a kind of submersible motor, such as figure 1 , figure 2 As shown, it includes a rotating shaft 1, a rotor 2, a stator 3, and a housing assembly 4 having an inner cavity 40 and an outer cavity 41. The housing assembly 4 includes a barrel 42, an upper fixing seat 43, a lower fixing seat 44, a shielding sleeve 45, Diaphragm 46 and base 47 and other components.

[0039] The upper fixing seat 43 is fixed and sealingly connected with the upper end of the barrel 42 , and the lower fixing seat 44 is fixed and sealingly connected with the lower end of the barrel 42 . The shielding sleeve 45 is located in the machine barrel 42, and the upper and lower ends of the shielding sleeve 45 are respectively fixed and sealed with the upper fixing seat 43 and the lower fixing seat 44. The space between them is the outer cavity 41 . The stator 3 is located in the outer cavity 41 and fixedly connected with the barrel 42 , the rotating shaft 1 is located in the inner cavity 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com