Reliable connection mode of motor circulation water path

A technology of circulating waterway and connection method, which is applied in the field of connection method of motor circulating waterway, can solve the problems of affecting cable layout, occupying a large space, inconvenient operation, etc., and achieve the effect of shortening the waterway circulation path, saving space and having a simple appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

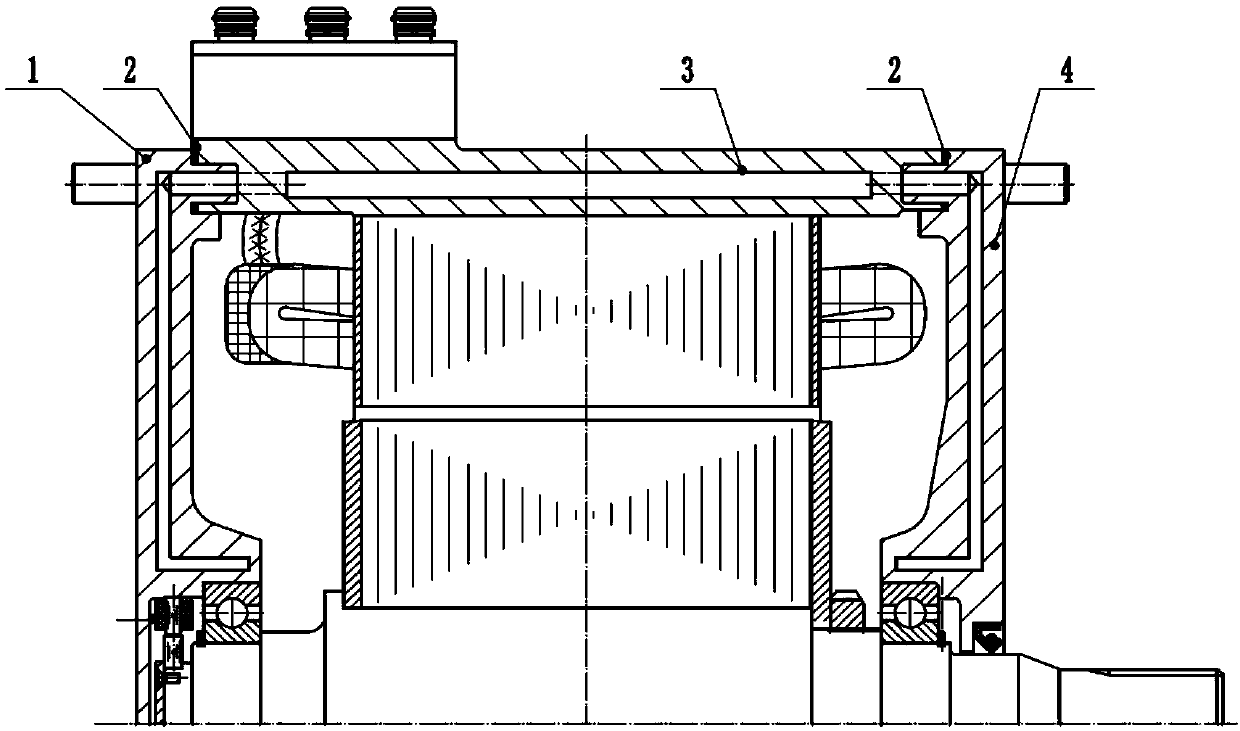

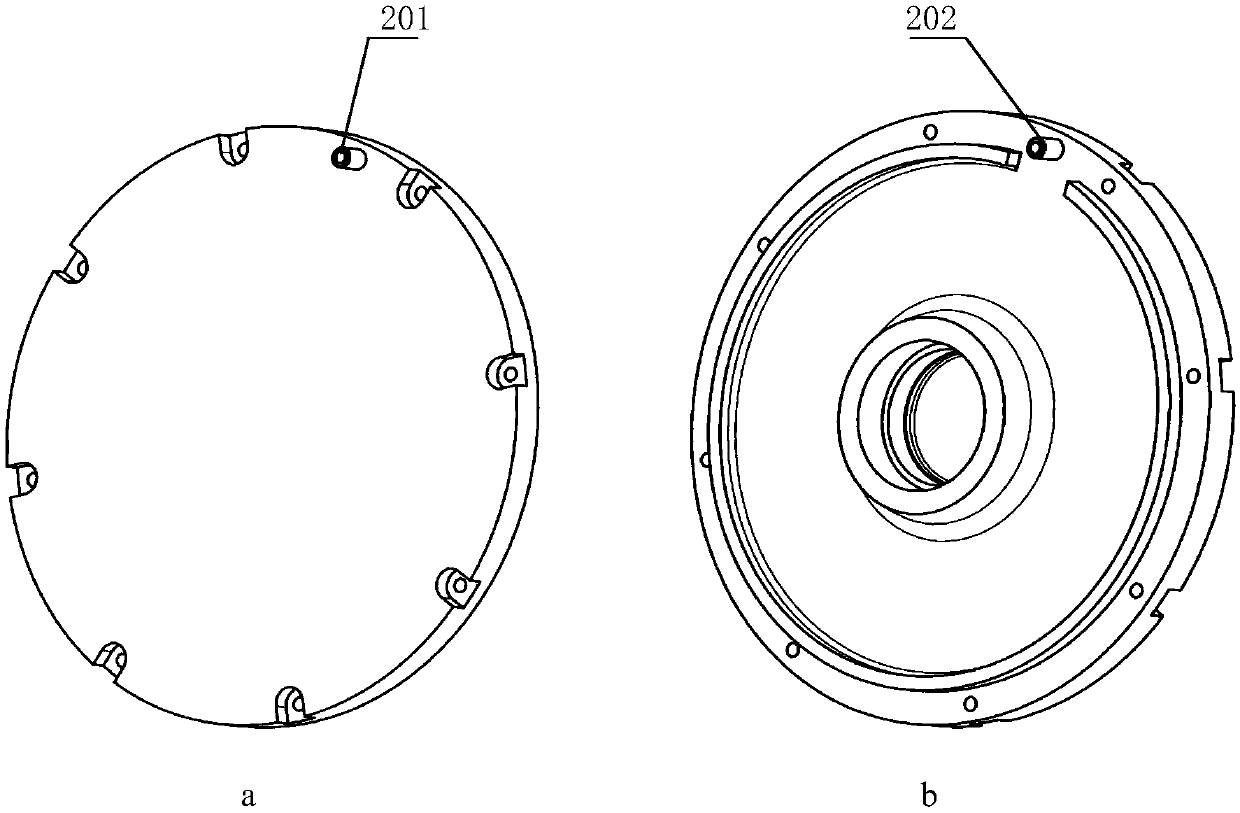

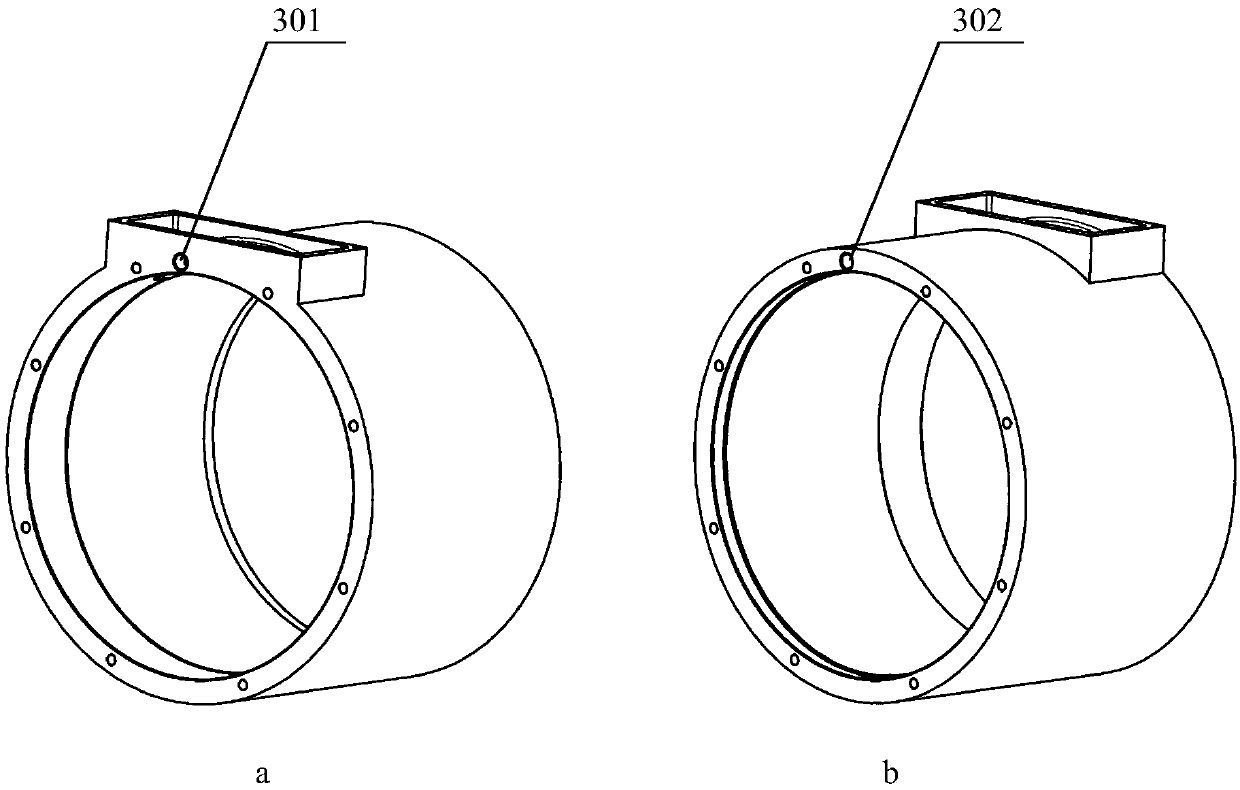

[0019] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the connection method of the present invention includes: a front end cover, a rear end cover, a housing and a gasket. The front end cover 1 is located at the front end of the motor and is connected with the housing 3 , and the rear end cover 4 is located at the rear end of the motor and is also connected with the housing 3 . When the front end cover 1 is connected with the housing, the water outlet 201 on the front end cover 1 is put into the water inlet 301 on the housing 3, and the gasket 2 is installed on the end surface of the housing 3, and fastened by bolts. When the rear end cover 4 is connected with the housing 3, the water inlet 401 on the rear end cover 4 is packed into the water outlet hole 302 on the housing 3, and the gasket 2 is installed on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com