Honing method with cross-grinding for gear wheels

A honing and gear technology, which is applied to components with teeth, gear tooth manufacturing devices, gear tooth manufacturing tools, etc., can solve problems such as high emissions and rapid gear wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

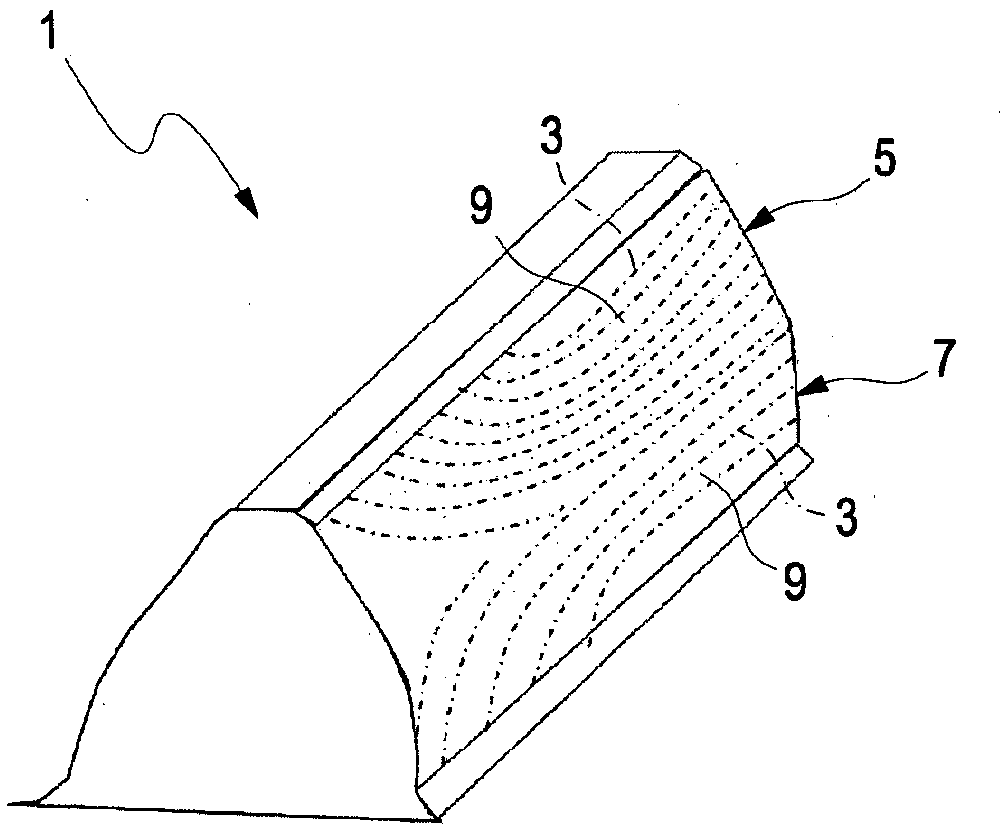

[0031] FIG. 1 shows a tooth 1 of a gear which has been machined by means of a honing ring in a method according to the prior art. The honing ring is already moved in one direction along the tooth 1 while maintaining the angle of intersection between the honing ring and the tooth 1 . Accordingly, a surface structure is formed on the tooth 1 , which surface structure each has grooves 3 running substantially parallel to one another on the upper part 5 and the lower part 7 of the tooth 1 . The furrows 3 at the upper part 5 are close to the furrows 3 at the lower part 7 here, but they do not intersect each other. That is to say, channels 9 are formed by the furrows 3 , through which lubricant, for example oil, can be guided away from the tooth 1 under the action of pressure, which occurs, for example, during use in transmissions, and the tooth is correspondingly less responsive to pressure loads. and temperature loads are protected.

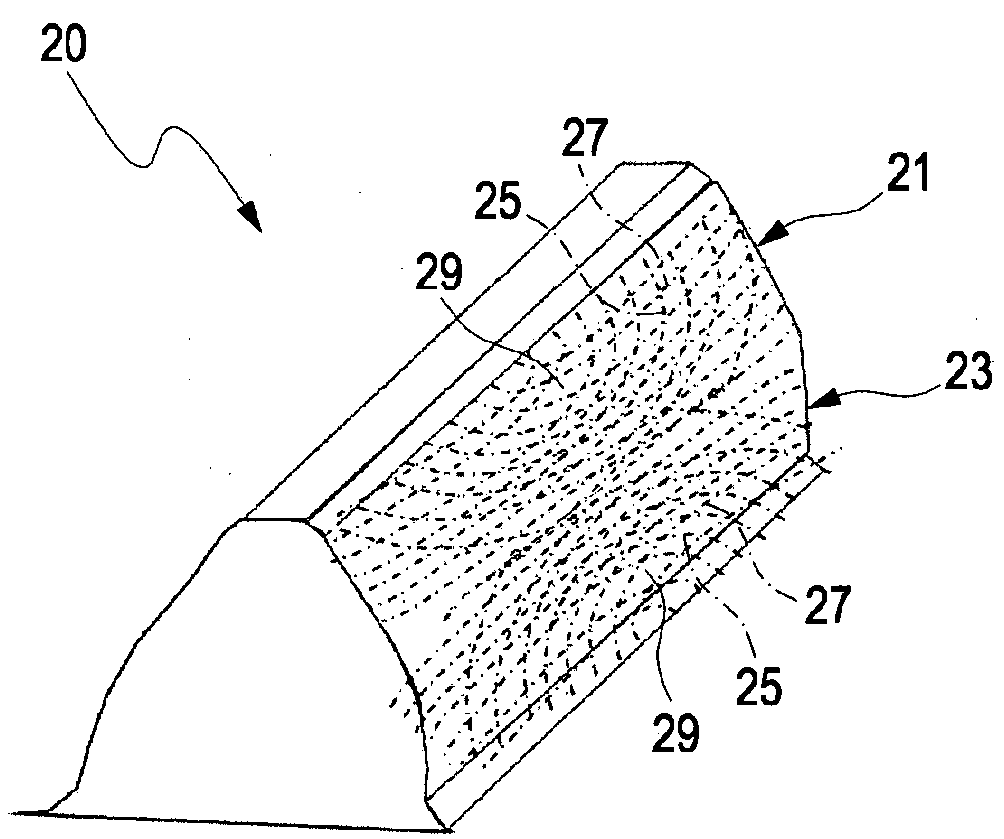

[0032] exist figure 2 A tooth 20 of a gear i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com