Method for identifying blocked pressure lines

A pressure pipeline and pressure technology, which is used in the field of identifying blocked pressure pipelines, and can solve problems such as HWL dispensing and pressure pipeline blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

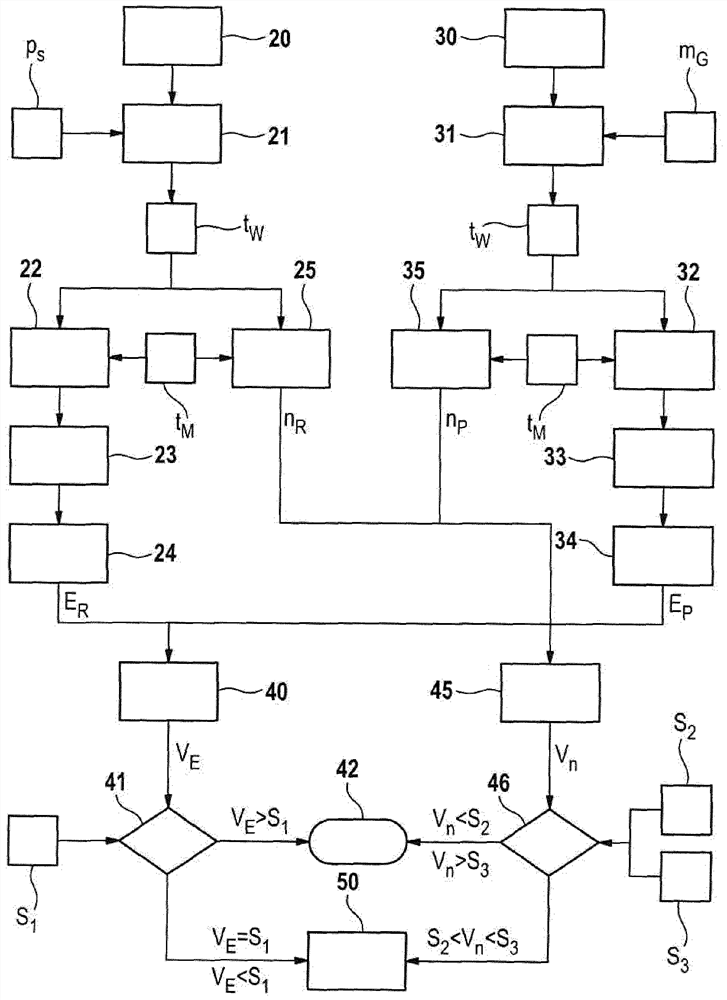

Method used

Image

Examples

Embodiment Construction

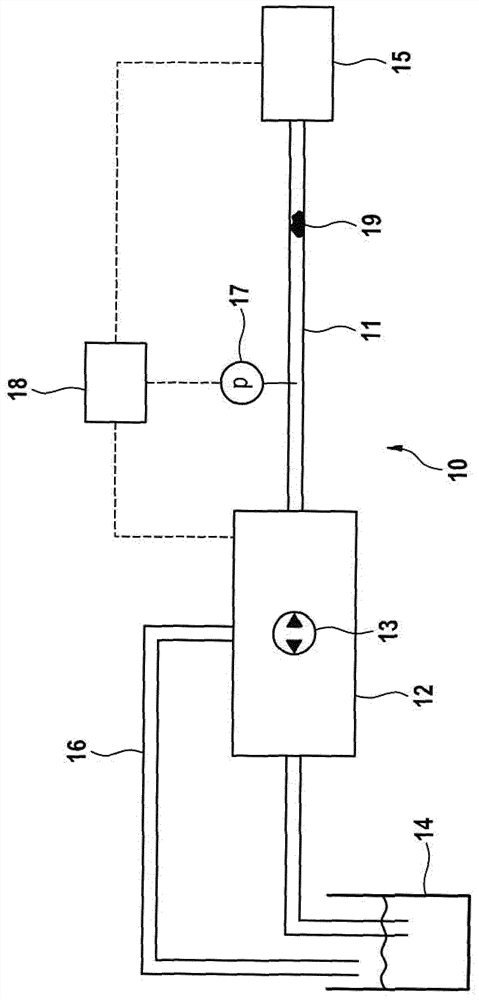

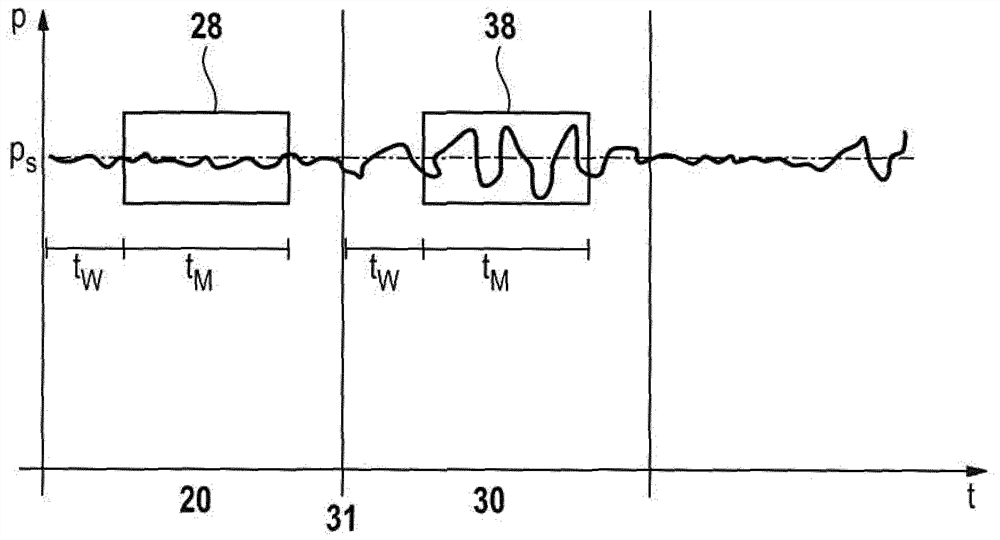

[0025] figure 1An SCR system 10 is shown for feeding reducing agent via a pressure line 11 into a not shown SCR catalytic converter. The SCR system 10 includes a delivery module 12 , which in turn includes a pump 13 , which is designed to deliver reducing agent out of a reducing agent tank 14 . The delivery module 12 is connected to the metering module 15 through the pressure pipeline 11, wherein the reducing agent is delivered from the delivery module 12 to the metering module 15 through the pressure pipeline 11, and the reducing agent in the metering module is subsequently Fitted into an exhaust system not shown. In addition, the SCR system 10 includes a return line 16 , which connects the delivery module 12 with the reducing agent storage tank 14 . The excess reducing agent is returned to the reducing agent storage tank 14 by the delivery module 12 . Furthermore, the pressure line 11 has a pressure sensor 17 which monitors the pressure p in the pressure line 11 and which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com