Three-wheel corn harvester with straw separation function

A harvester and functional technology, which is applied in the field of three-wheel corn harvesters, can solve the problems of difficult separation, decreased corn harvesting quality, and easy mixing of corn and finely crushed stalks, and achieves the effect of ensuring harvesting quality and avoiding mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

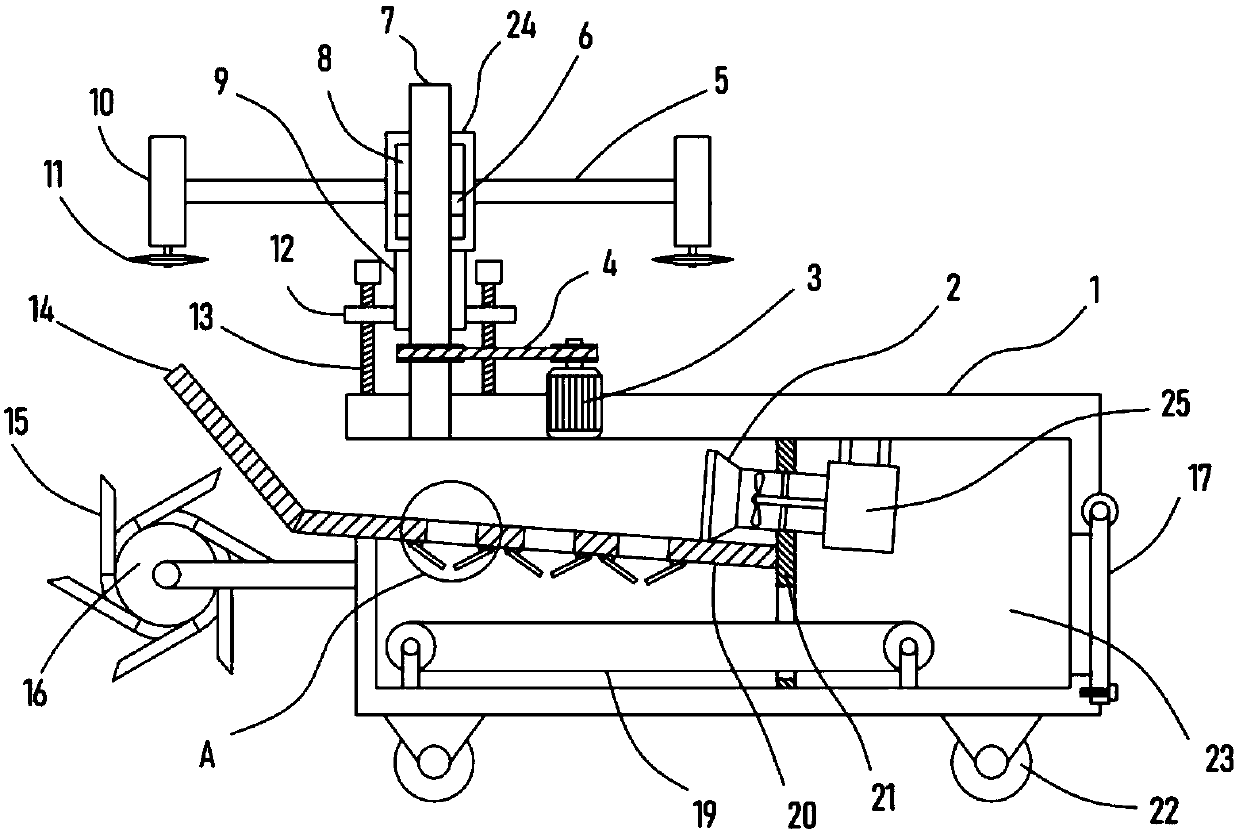

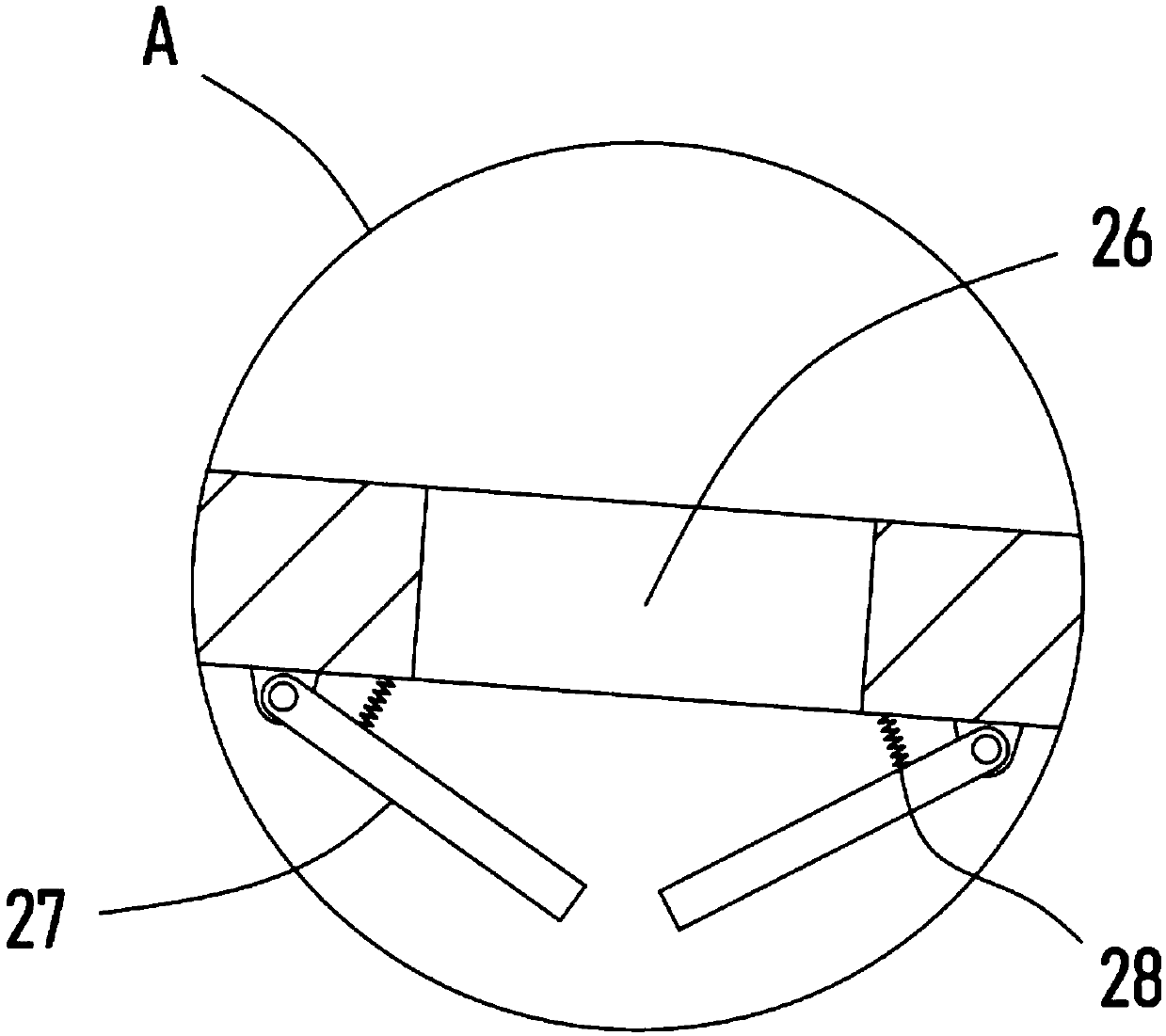

[0023] see Figure 1-5 , a three-wheeled corn harvester with straw separation function, including a support box 1, the bottom of the support box 1 is rotatably provided with walking wheels 22, and the number of walking wheels 22 is at least three, which can be driven and rotated by a motor to realize the present invention. The overall movement of the device.

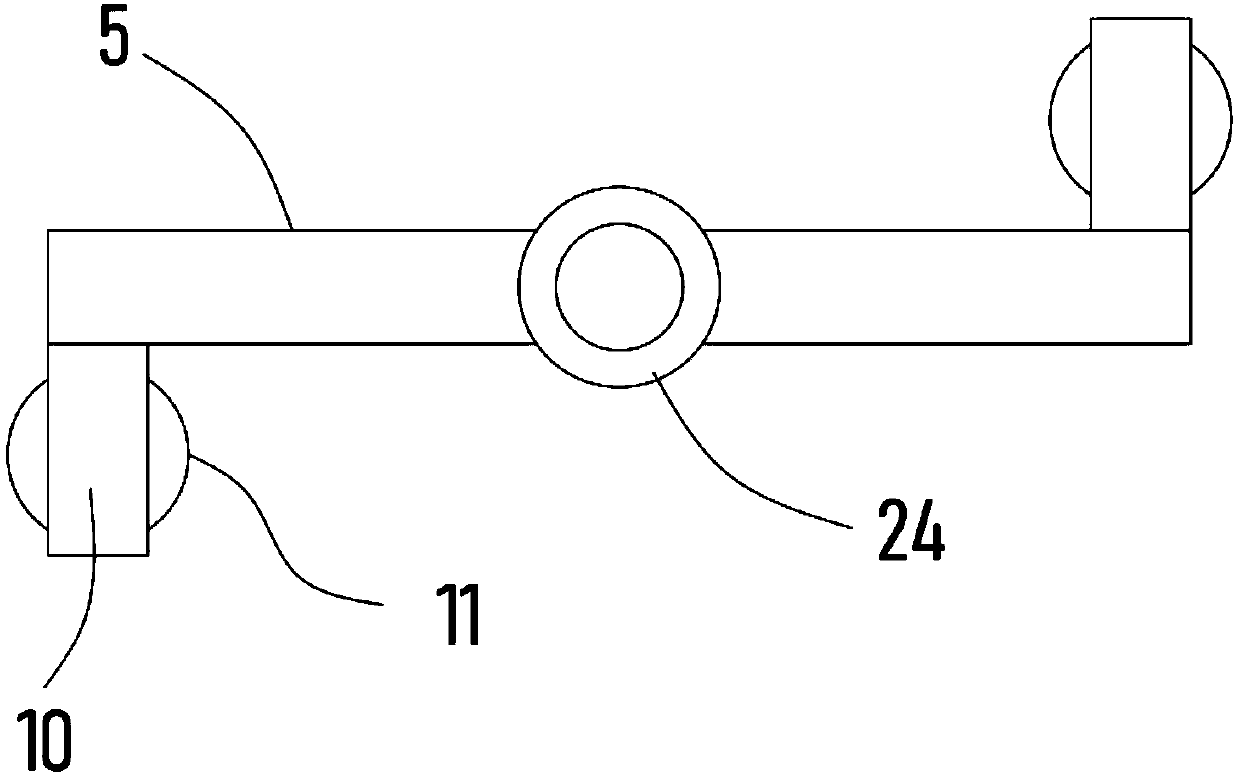

[0024] The top of the support box 1 is rotatably provided with a rotating shaft 7, the rotating shaft 7 is covered with a transmission sleeve 24, the side wall of the transmission sleeve 24 is horizontally fixed with a rotating rod 5, and the end of the rotating rod 5 is vertically fixed with a dial 10, A blade 11 is fixed on the bottom of the dial 10, and the rotation of the rotating shaft 7 drives the transmission sleeve 24 to rotate.

[0025] Further, the inner side wall of the transmission sleeve 24 is vertically provided with a longitudinal transmission groove 8, and the side wall of the rotating shaft 7 is fixedly...

Embodiment 2

[0029] On the basis of Embodiment 1, in addition, the movable sleeve on the rotating shaft 7 is provided with a lifting sleeve 9 whose upper end abuts against the lower end of the transmission sleeve 24, and the lifting sleeve 9 is sleeved with a fixed limit sleeve plate 12, and the limit sleeve The plate 12 is threadedly connected with a threaded rod 13. By turning the threaded rod 13, the limit sleeve plate 12 can drive the lifting sleeve 9 to adjust the height up and down, and then the transmission sleeve 24 together with the rotating rod 5, the shifting plate 10 and the blade 11 can be adjusted up and down. The adjustment of the position enables the cutting height of the blade 11 to be adjusted, which is convenient for harvesting corncobs of different heights.

[0030] Further, a dividing plate 21 is vertically provided in the supporting box 1, and a transmission belt 19 positioned below the separation plate 20 is worn on the dividing plate 21, and a collection box 23 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com