Anti-rust color steel tile locking clip and pressing roller of tile pressing machine

The technology of a tile pressing machine and a pressing roller is applied in the field of pressing rollers and locking clips for color steel tile processing equipment, and can solve problems such as corrosion and damage to the anti-rust layer of color steel tiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

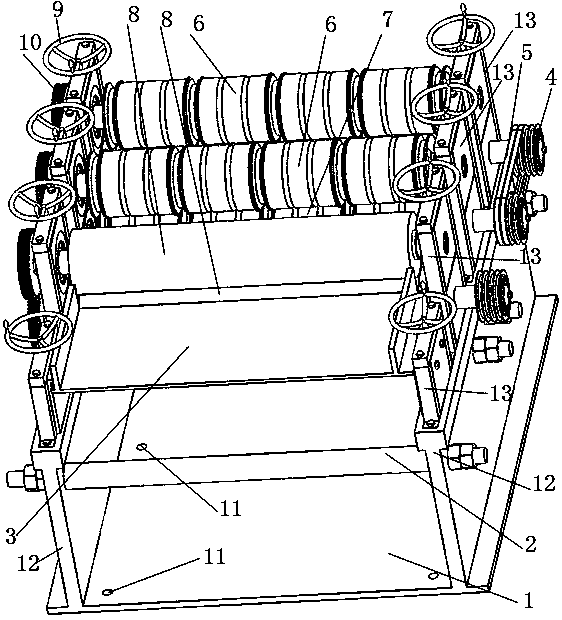

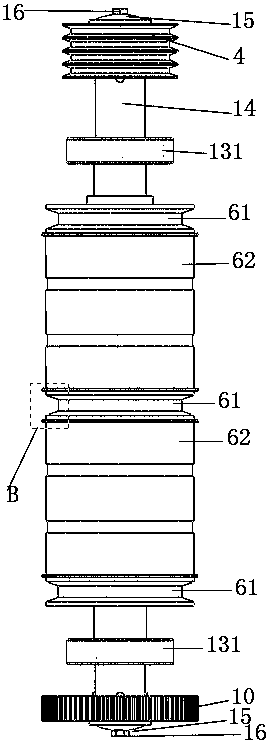

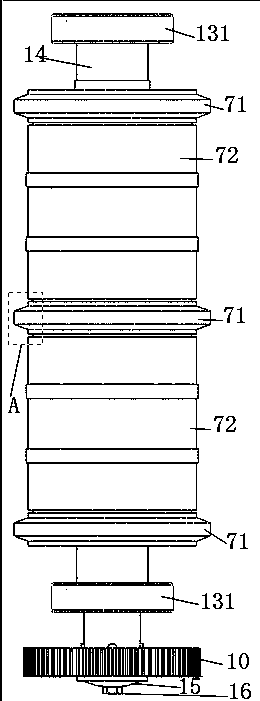

[0030] attached figure 1 It is a structural schematic diagram of a tile press. The tile press is mainly composed of a frame 1, a tie rod 2, a material table 3, a pulley 4, a belt 5, a pressure roller A6, a pressure roller B7, a rubber roller 8, a hand wheel 9, and a gear 10. There are mounting holes 11 on the frame 1 for fixing the tile press, and there are left and right mounting frames 12 on the frame 1, which are respectively used to install the bearing housing 13, the bearing housing 13 is equipped with a bearing 131, and the bearing 131 is used to install the main shaft 14 , the main shaft 14 is the central axis of the pressure roller A6, the pressure roller B7, and the rubber roller 8. The two main shafts 14 are installed up and down, and the steel coil is pressed by the pressure roller A6, the pressure roller B7 or a pair of rubber rollers 8. The upper and lower main shafts have a main shaft Belt pulley 4 is installed at one end of 14, and the power is transmitted to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com