Optical lens grinding machine

A technology for optical lenses and grinding machines, which is applied to optical surface grinders, optics, and optical components. It can solve the problems of expensive equipment, complicated replacement parts, and complex structures, so as to improve operating efficiency, avoid collision wear, and reduce operating manpower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

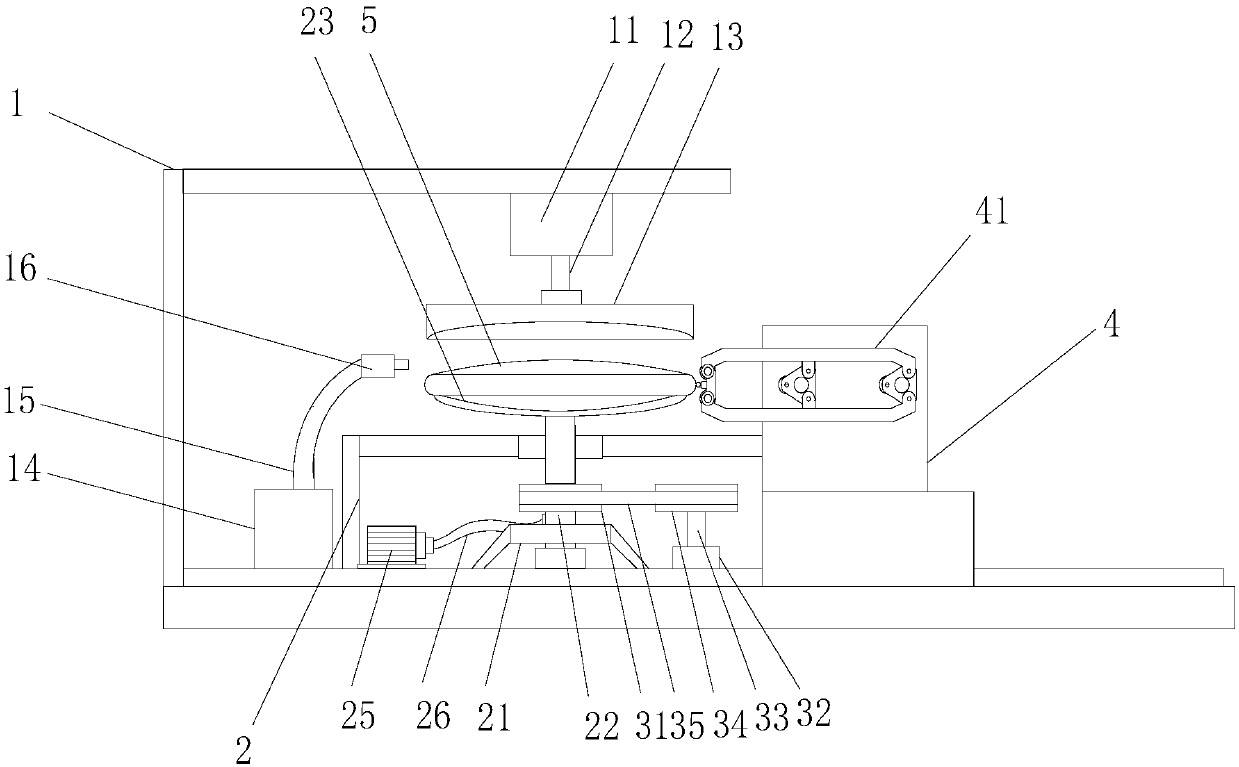

[0027] see figure 1 , an optical lens grinding machine, comprising a frame 1, a transmission frame 2 is installed on the bottom plate of the frame 1, a support column 22 is vertically installed on the transmission frame 2, and the bottom end of the support column 22 passes through The bearing is installed on the bottom plate of the frame 1, and the bottom end of the support column 22 is equipped with a support frame 21. The support frame 21 is inclined to support and the end is fixed on the bottom plate of the frame 1. The support mechanism ensures that the support column 22 stability.

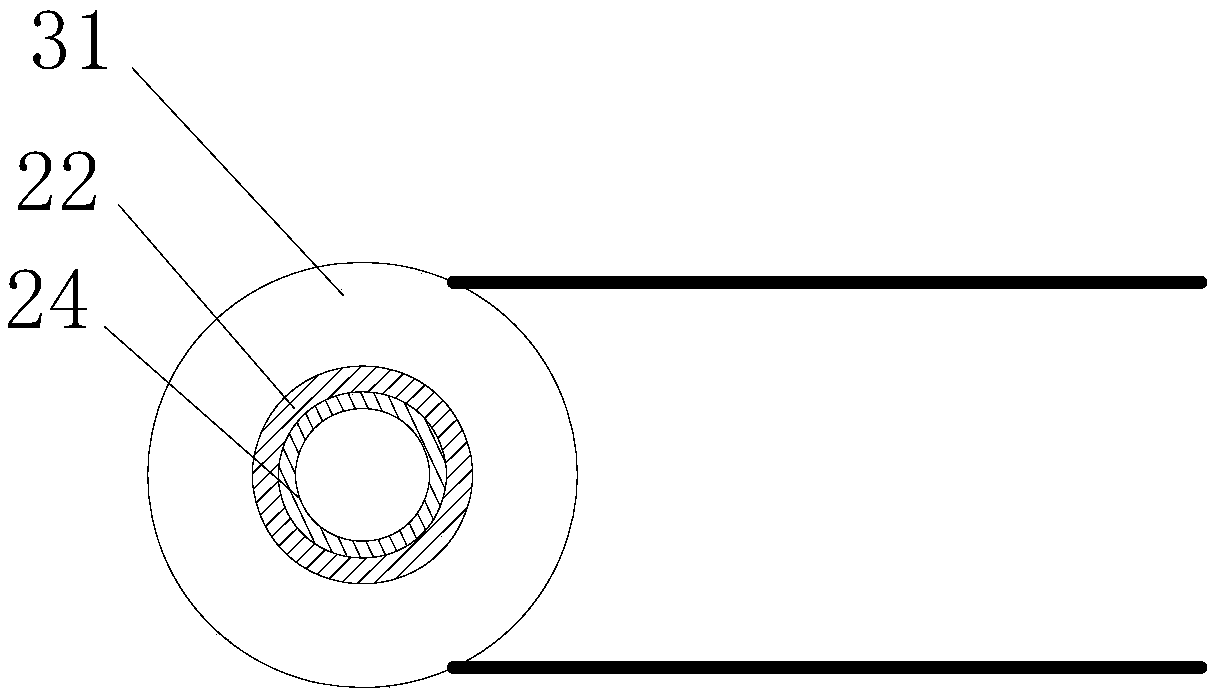

[0028] see figure 1 and figure 2 , the top of the support column 22 is equipped with a suction cup 23, the support column 22 is a hollow structure, the inner cavity of the support column 22 is provided with an air suction pipe 24, and the transmission frame 2 is equipped with an air suction pump 25, The suction end of the suction pump 25 is equipped with an air guide pipe 26, the bottom en...

Embodiment 2

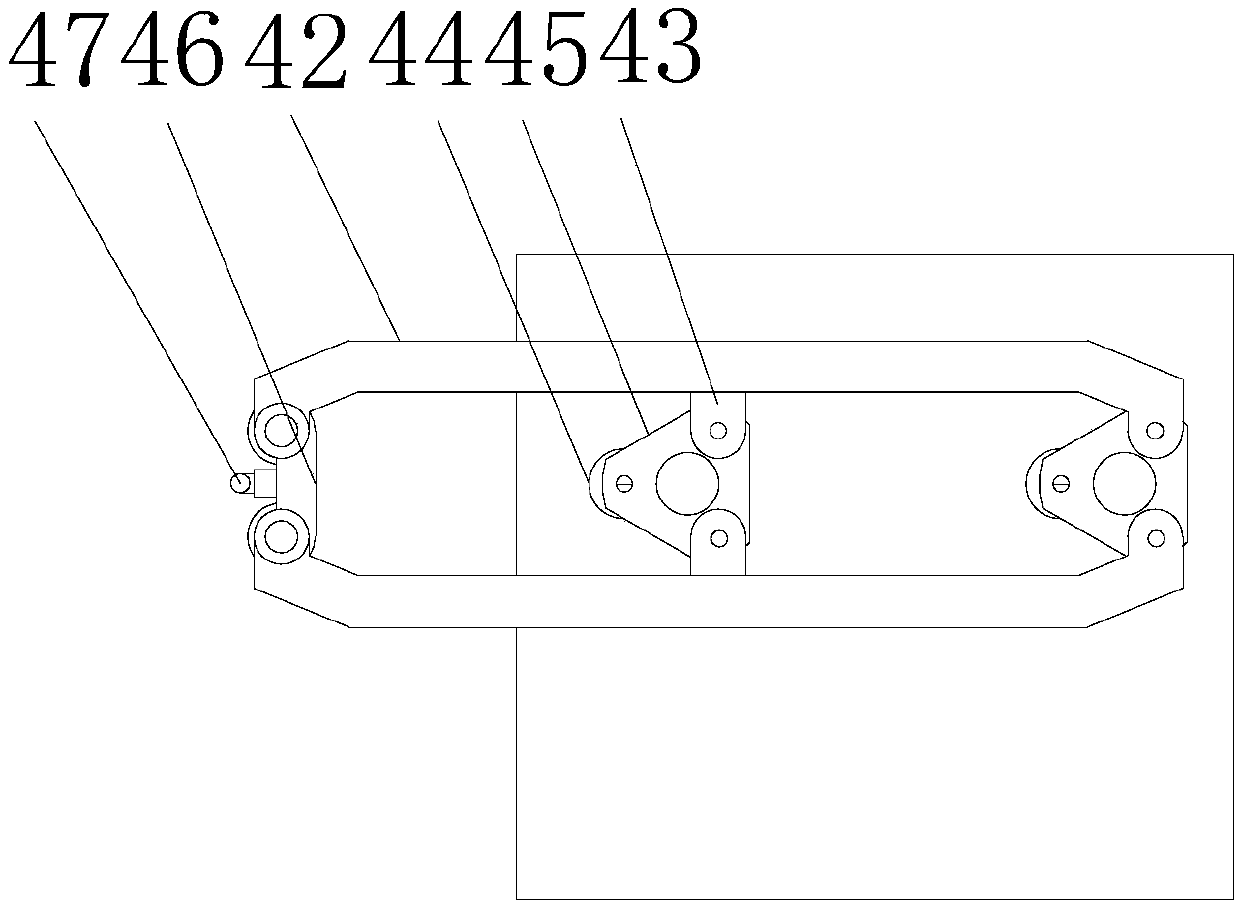

[0033] see figure 1 and image 3 , this embodiment is a further optimization of Embodiment 1. On the basis of it, a side machine 4 is installed on the side of the frame 1, and a side grinding frame 41 is installed on the side machine 4. The side The edge grinding frame 41 comprises a transmission link 42, and the transmission link 42 is respectively located on the upper and lower sides and is equipped with a fixed rod 43. A tripod 45 is installed between the transmission connecting rods 42 on both sides, and the tripod 45 is an isosceles triangle structure, and the fixed rods 43 are installed at the adjacent bottom corners of the tripod 45 respectively, and the transmission connecting rod 42 The front end of the grinding seat 46 is equipped with a grinding seat 46, the upper and lower ends of the grinding seat 46 are connected with the transmission connecting rod 42 by locking bolts, and the front end of the grinding seat 46 is equipped with a grinding head 47. Drive motors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com