Inorganic material cutting device

A cutting device and inorganic material technology, applied in the direction of metal processing, etc., can solve the problems of insignificant cutting effect of inorganic materials, large error of test results, irregular samples, etc., and achieve the effect of improving cutting quality, improving precision and reducing operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

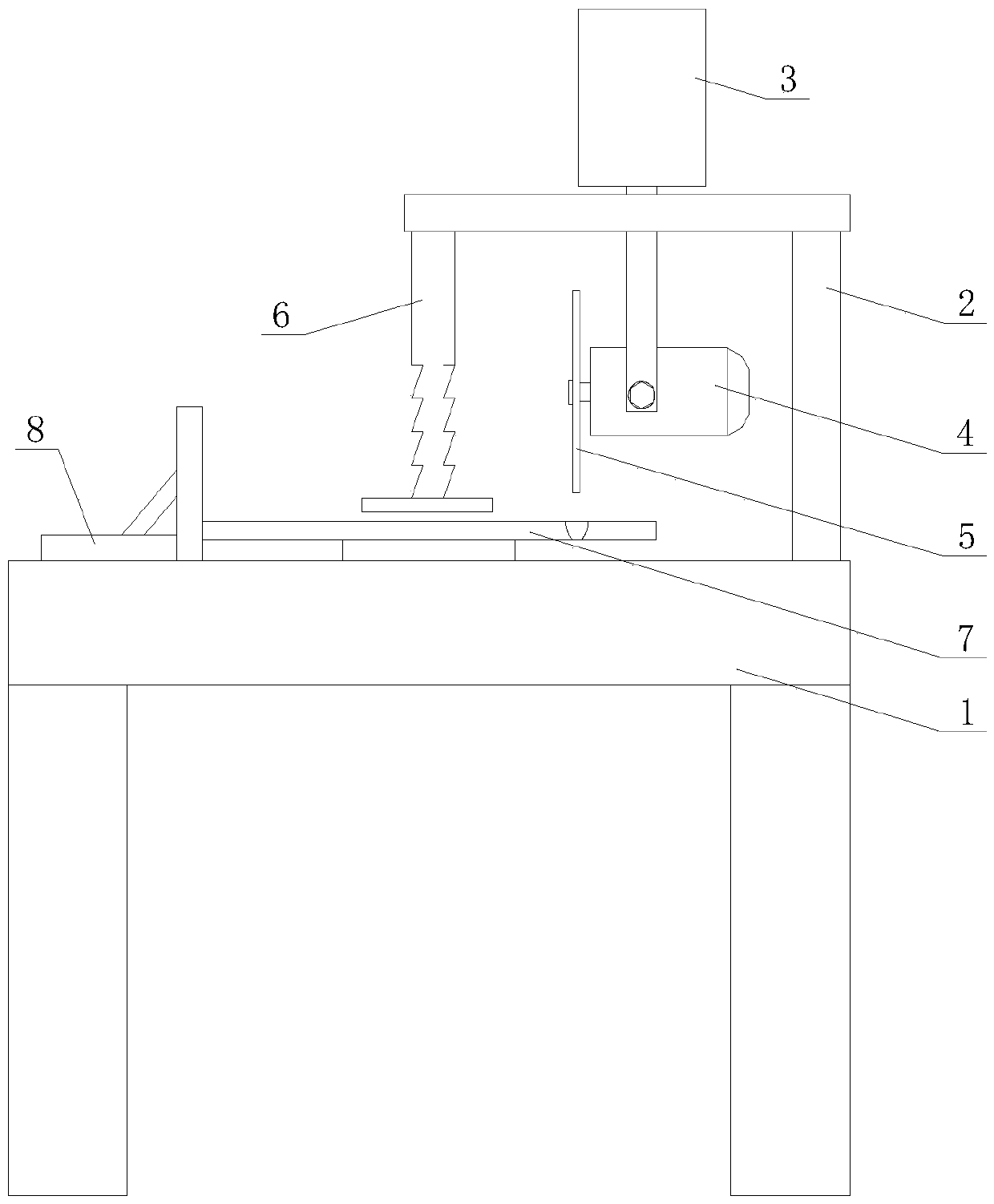

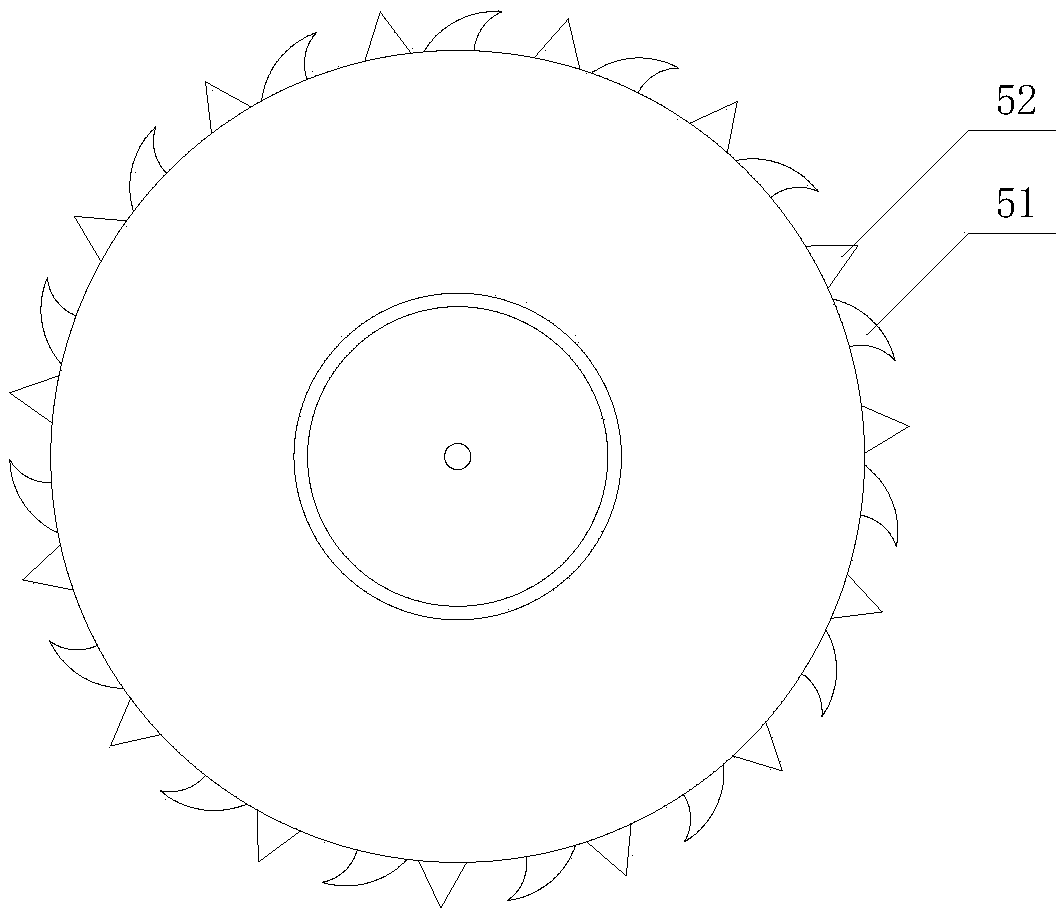

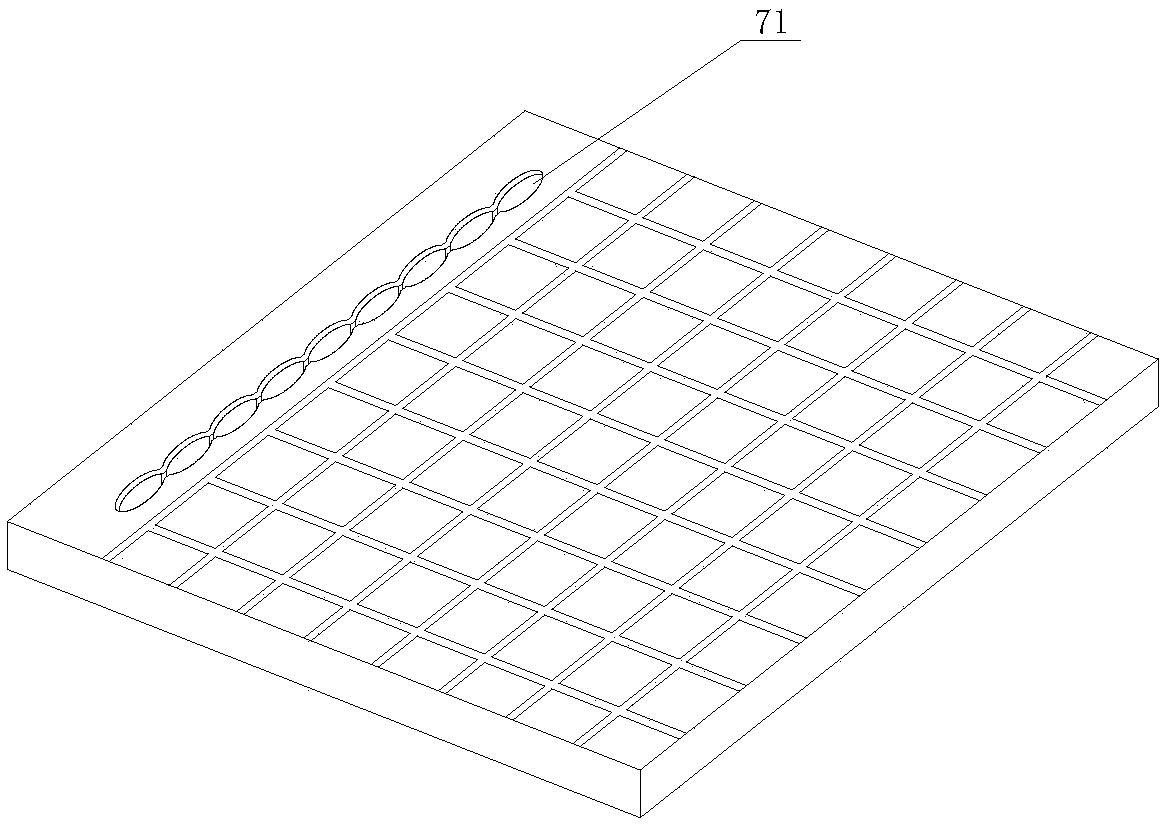

[0024] From Figure 1-4 It can be seen that an inorganic material cutting device in this embodiment includes a frame 1, a right-angle support plate 2 is arranged on the upper surface of the frame 1, the right-angle support plate 2 is fixedly welded to the frame 1, and the right-angle support plate 2 is connected to the machine frame. The gap between the frames 1 is the operating space. At the same time, the right-angle support plate 2 can block some impurities and prevent them from being raised. The upper surface of the right-angle support plate 2 is equipped with a hydraulic cylinder 3, and the bottom of the hydraulic cylinder 3 is equipped with a stepping motor. 4. The output end of the hydraulic cylinder 3 runs through the right-angle support plate 2 and is detachably assembled with the stepping motor 4. When the stepping motor 4 is damaged, the stepping motor 4 can be removed for replacement. The output end of the stepping motor 4 is set There are alloy disc blades 5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com