Planning method of laser deposition scanning path

A scanning path and laser deposition technology, applied in the field of additive manufacturing, can solve problems such as affecting the bonding between the original layer and the replica layer, low forming efficiency, affecting forming speed efficiency and quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the examples, but not limited thereto.

[0034] In order to solve the problems of low forming efficiency and poor quality of parts, the present invention provides a laser deposition scanning path planning method.

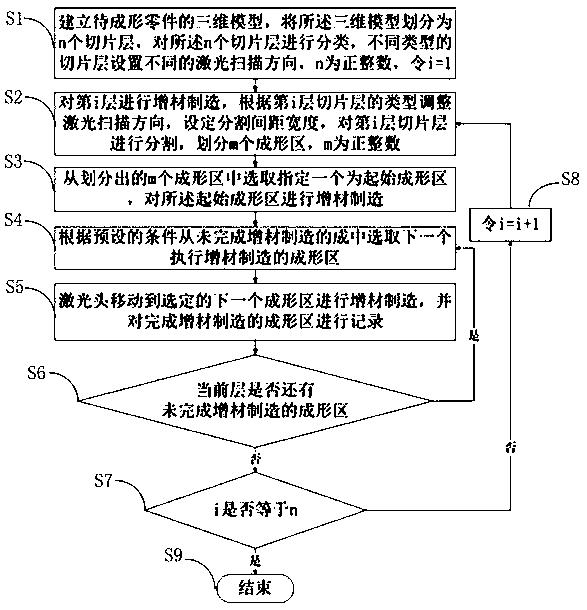

[0035] like figure 1 As shown, a laser deposition scanning path planning method provided by the present invention is characterized in that it includes the following steps:

[0036] S1. Establish a three-dimensional model of the part to be formed, divide the three-dimensional model into n slice layers, classify the n slice layers, set different laser scanning directions for different types of slice layers, n is a positive integer, let i=1;

[0037] Wherein, the concrete steps of step S1 are:

[0038] S101, using 3D software to establish a 3D model of the part to be formed;

[0039] S102. Layer and slice the three-dimensional model, divide it into n slice layers, number the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com