Flight control simulator tensile and compressive load testing system field calibration device

A technology of flight control and load test, applied in the field of measurement and calibration, to achieve the effect of facilitating digital comparison and reducing the time difference of readings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

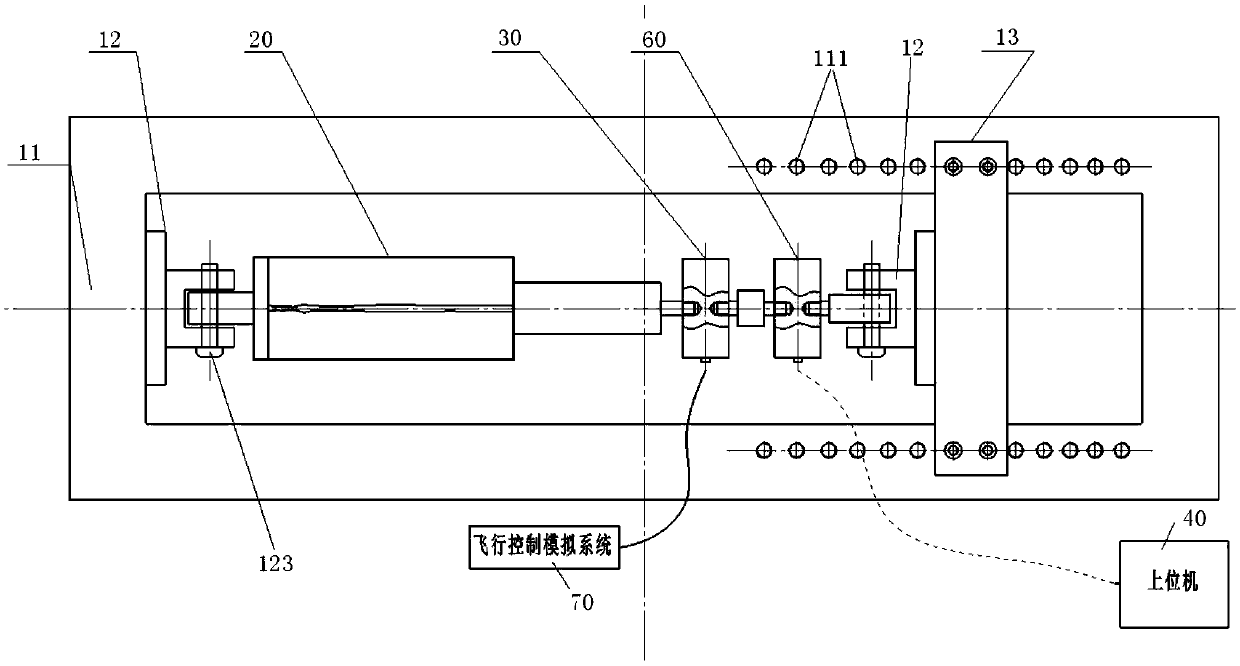

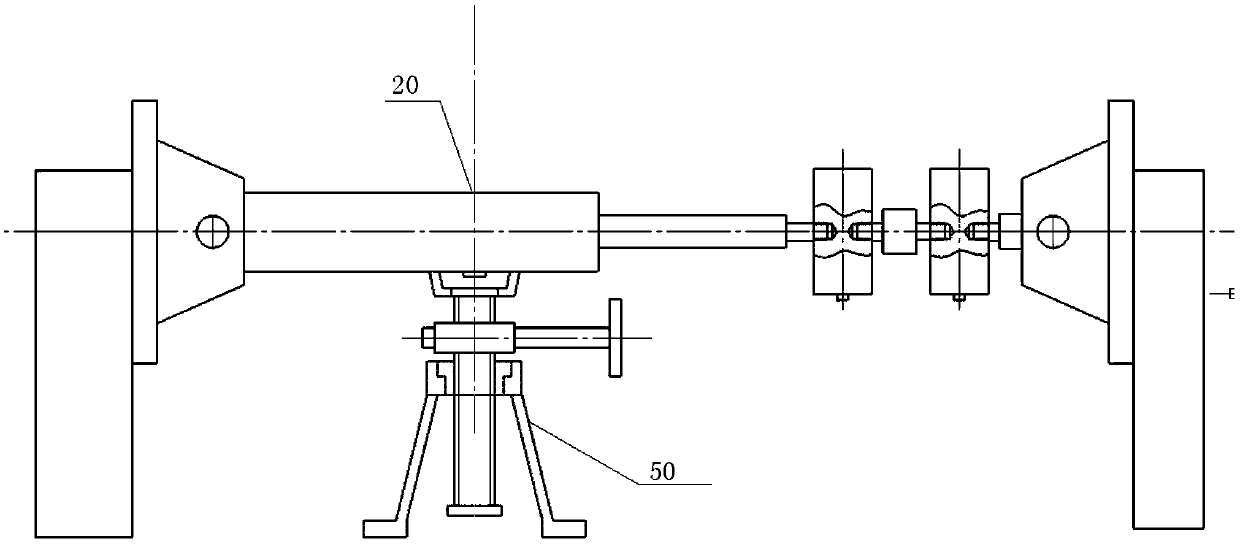

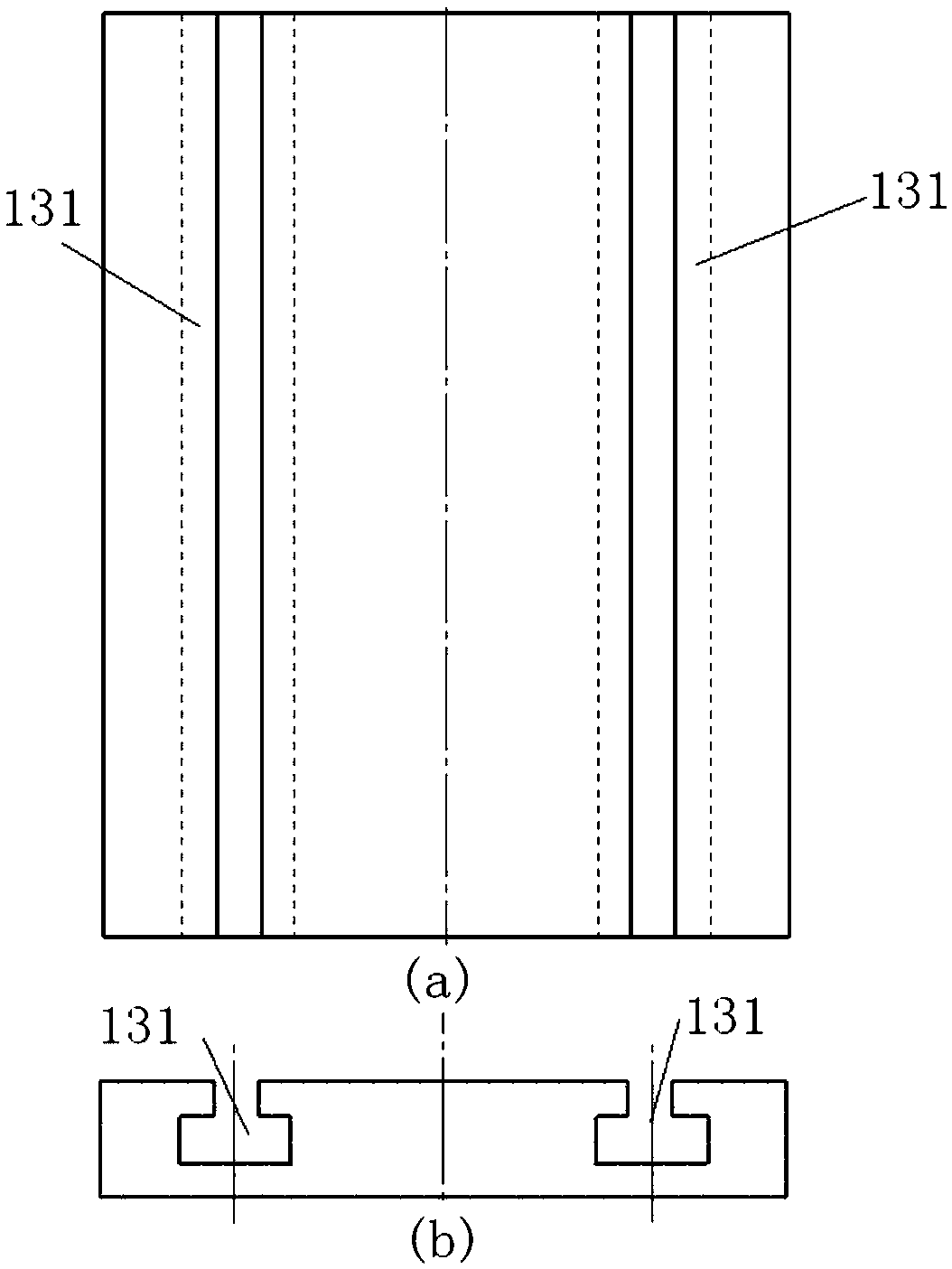

[0028] The following will combine Figure 1 ~ Figure 4 The on-site calibration device of the flight control simulator tension and compression load test system of the present invention is further described in detail.

[0029] figure 1 Shown is a top view of the on-site calibration device of the flight control simulator tension and compression load test system of a preferred embodiment of the present invention; figure 2 Shown is a schematic diagram of the fine-tuning mechanism in a preferred embodiment of the present invention.

[0030] see figure 1 , the on-site calibration device of the flight control simulator tension and compression load test system of this embodiment includes a structural frame, a loading mechanism 20, a standard measurement unit 30, a host computer 40 and a fine-tuning mechanism 50;

[0031] The loading mechanism 20, the standard measuring unit 30 and the calibrated force sensor 60 are sequentially connected and installed on the structural frame;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com