Glass transportation frame

A transport frame and glass technology, applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of glass transportation and cumbersome methods, and achieve the effect of convenient transportation, reliable clamping and fast clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

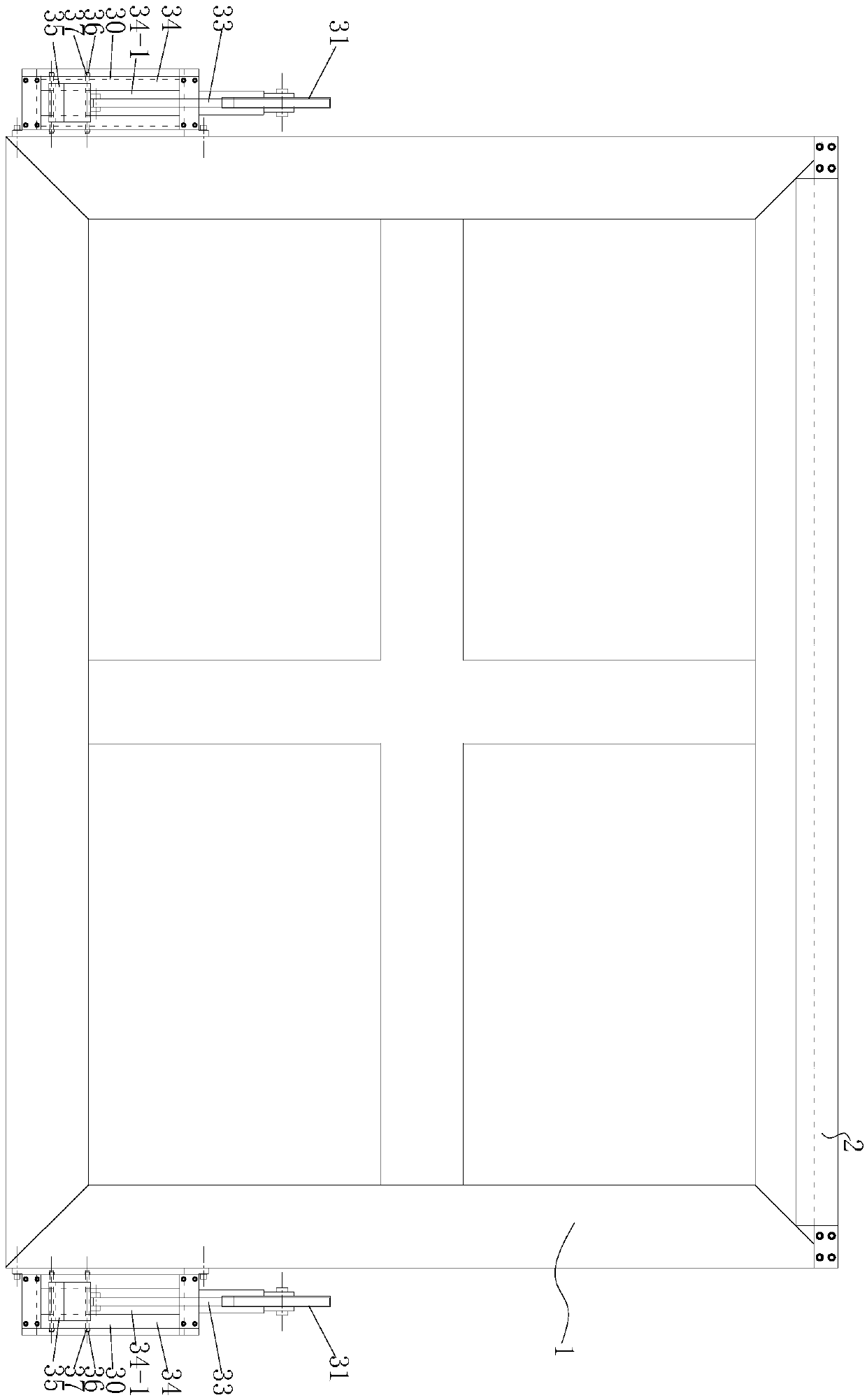

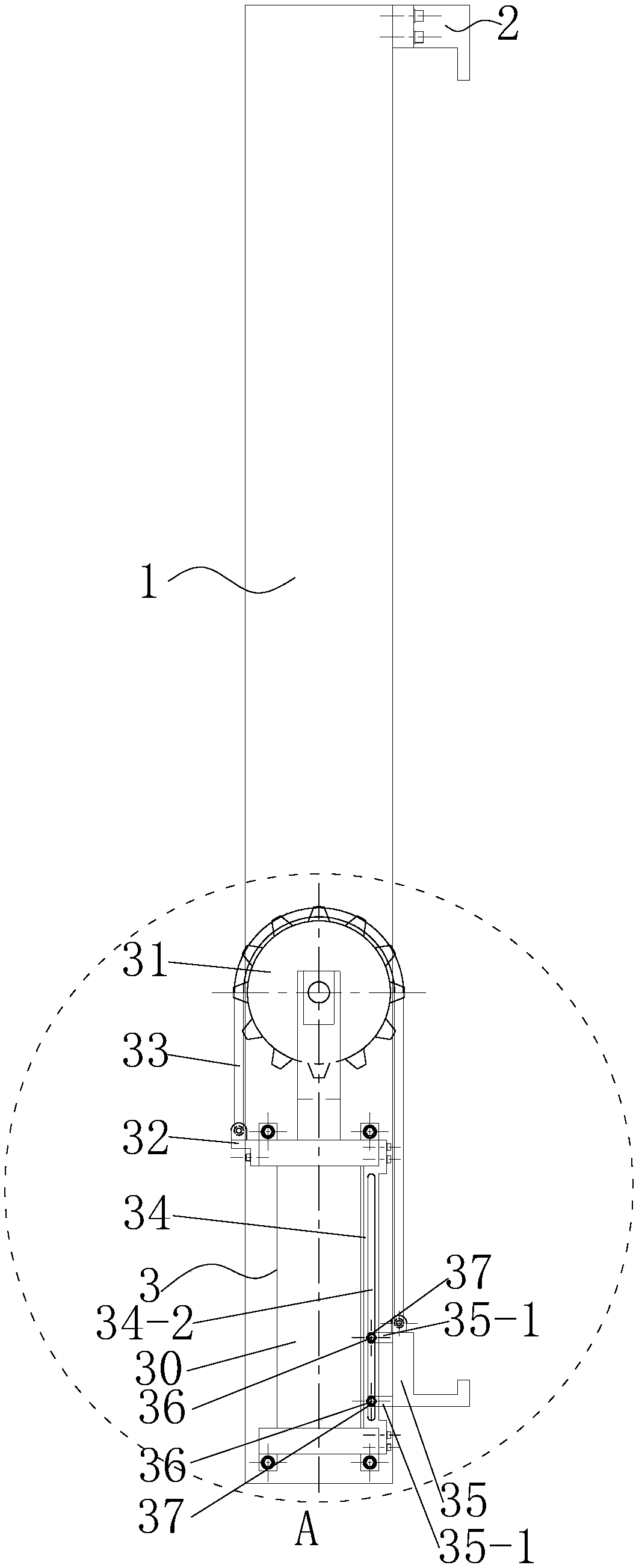

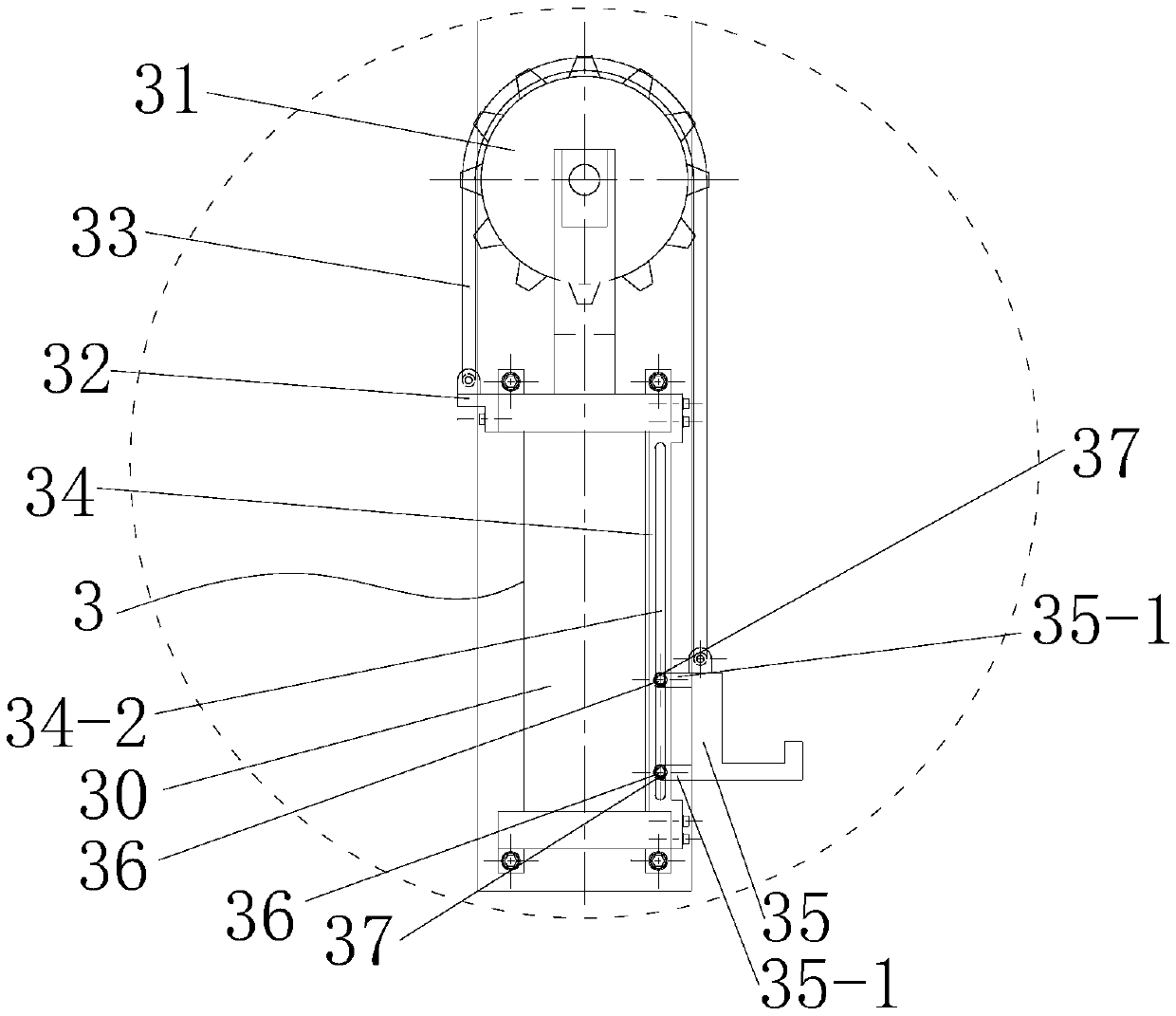

[0024] In this glass transport rack, the piston rod of the hydraulic cylinder 30 in the lifting mechanism 3 is first contracted to the shortest state, so that the lifting buckle 35 is at the lowest position, and then the glass is hoisted to the lifting buckle 35 by driving and placed vertically, and then the transportation is started at the same time The lifting mechanism 3 on both sides of the frame 1, the piston rods of the two hydraulic cylinders 30 are extended at the same time, the sprocket 31 rotates with the piston rods of the hydraulic cylinder 30 extending upward, and then the chain 33 pulls the buckle 35 along the guide The guide groove 34-1 in the plate 34 moves upwards to lift the glass until the uppermost end of the glass contacts the top buckle 2, and then stops the hydraulic cylinder 30 from working. According to the different sizes of the glass, the piston rod of the hydraulic cylinder 30 will Different elongation lengths realize fast clamping of glass of differ...

Embodiment 2

[0026] On the basis of Embodiment 1, the end of the piston rod of the hydraulic cylinder 30 is provided with a rectangular notch, which facilitates the installation of the sprocket 31; Horizontal sliding; the guide groove 34-1 is a rectangular groove, the limit groove 34-2 is a waist-shaped long groove, the pin shaft 36 passes through the limit groove 34-2 and the guide block 35-1, and the pin Axle 36 is screwed on lock nut 37, guarantees that buckle 35 only moves in the vertical direction, has avoided buckle 35 to disengage from guide groove 34-1, and clamping is reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com