Color masterbatch compound and preparation method thereof

A technology of mixtures and color masterbatches, applied in the field of color masterbatch mixtures and their preparation, can solve the problems of large particle size damage of pearlescent powder, poor dispersion effect of organic pigments, limited improvement of pearlescent texture, etc., and achieve excellent pearlescent effect , good color and permeability, improve the effect of pearlescent texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0037] The preparation method of the masterbatch compound of the present embodiment is specifically as follows:

[0038] ① Preparation of high-concentration single-color masterbatch.

[0039] Add 4.2kg of LLDPE resin, 2.52kg of organic pigments and 0.28kg of polyethylene wax into a continuous internal mixer (sourced from Farrell, USA), and continuously banbury at a temperature of 185±2°C for 3 to 5 minutes , and then granulated to obtain 7kg high-concentration single-color masterbatch.

[0040] The concentration of the organic pigment in the high-concentration single-color masterbatch is 36wt%.

[0041] The organic pigment used in this embodiment is C.I. Pigment Yellow 17.

[0042] ② Preparation of low-concentration single-color masterbatch.

[0043] Mix 7kg of high-concentration single-color masterbatch prepared in step ① with 28kg of LLDPE resin, then add it to a single-screw extruder, extrude and knead, strand water-cooled, and pelletize to obtain 35kg of low-concentrati...

Embodiment 2~ Embodiment 3)

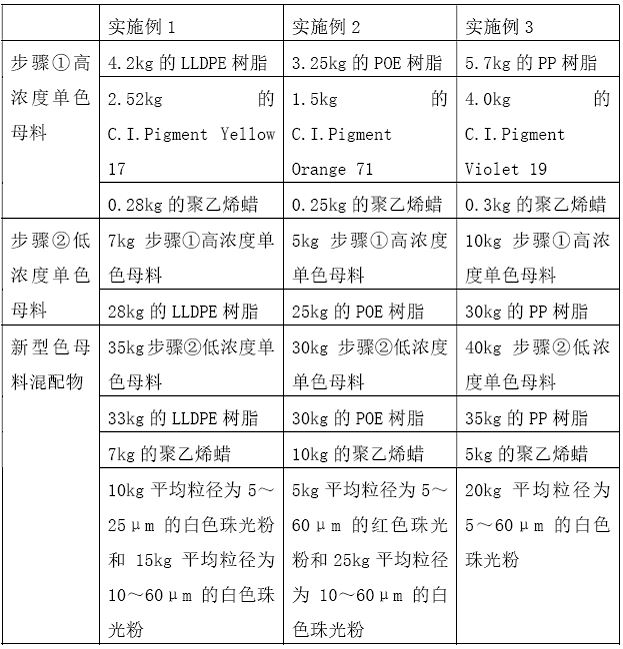

[0054] The preparation method of each embodiment is basically the same as that of Example 1, and the differences are shown in Table 1.

[0055] Table 1

[0056]

Embodiment 4~ Embodiment 6)

[0058] The preparation method of each embodiment is basically the same as that of Example 1, and the differences are shown in Table 2.

[0059] Table 2

[0060] Example 1 Example 4 Example 5 Example 6 Resin added in step ① 4.2kg of LLDPE resin 4.2kg of LLDPE resin 4.2kg of LDPE resin 2.1kg of LDPE resin + 2.1kg of LLDPE resin Resin added in step ② 28kg of LLDPE resin 28kg of LLDPE resin 28kg of EVA resin 14kg of LDPE resin + 14kg of LLDPE resin Resin added in step ③ 33kg of LLDPE resin 33kg of EVA resin 33kg of LLDPE resin 16kg of LLDPE resin + 17kg of LLDPE resin

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com