Environment-friendly template paint and preparation method thereof

A stencil paint, an environmentally friendly technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of short storage period, poor heat and alkali resistance, poor wear resistance, etc., achieve good storage stability, simple and convenient construction, The effect of improving appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0048] Embodiment 1-8 prepares environment-friendly template paint A1~A8

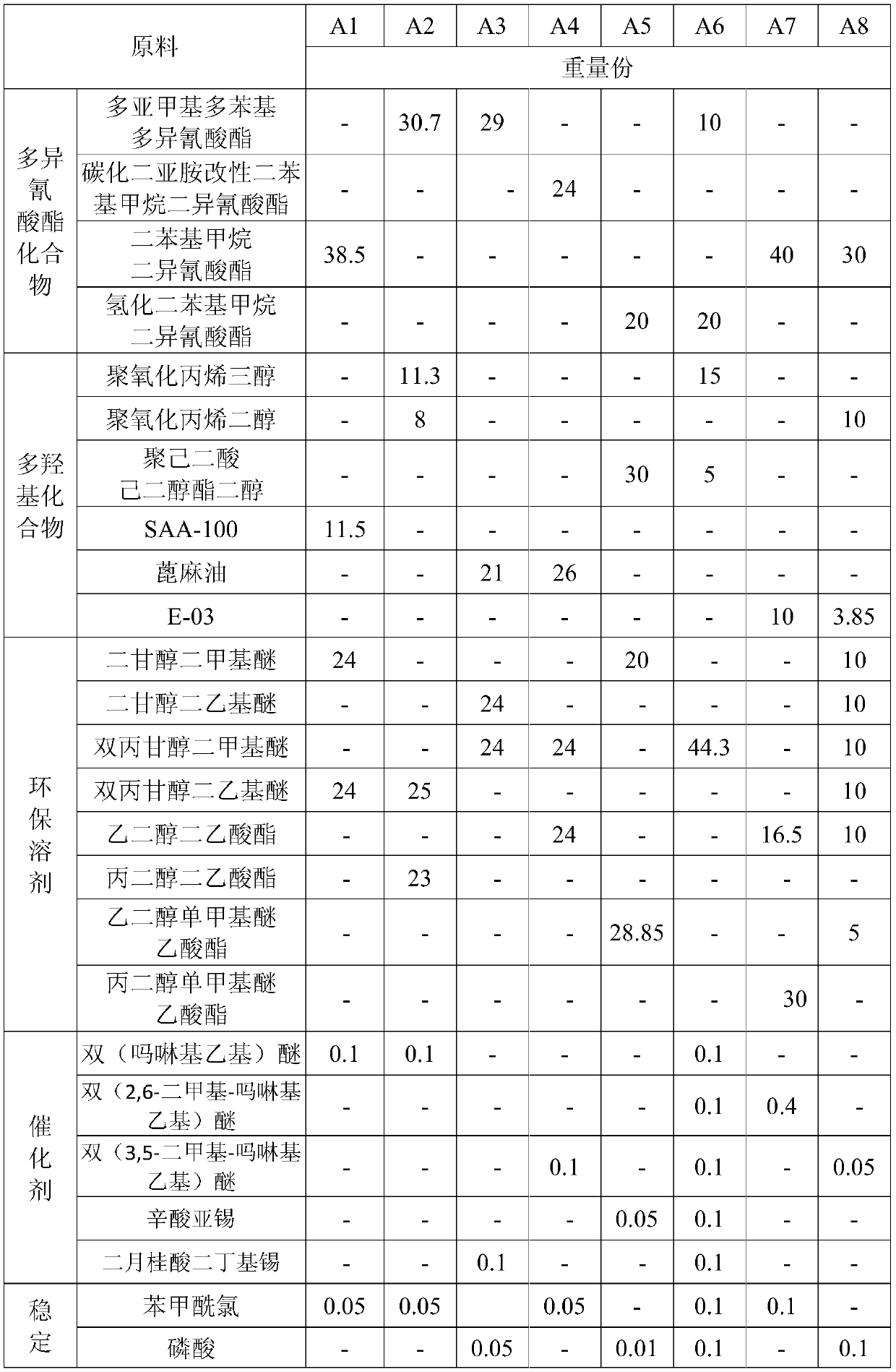

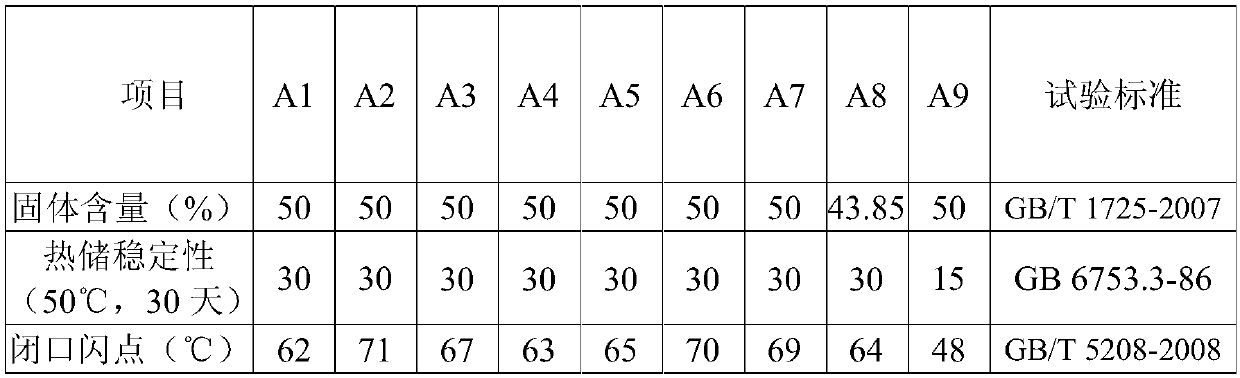

[0049] The formula of environment-friendly stencil paint is shown in Table 1.

[0050] Table 1 Formula of environment-friendly stencil paint

[0051]

[0052]

[0053] The preparation method of environment-friendly template paint comprises the following steps:

[0054] (1), at room temperature, add the environment-friendly solvent of formula quantity in reaction kettle;

[0055] (2) Under the condition of stirring, add the formula amount of polyisocyanate compound, polyhydroxy compound, catalyst and stabilizer to the reaction kettle in sequence, after stirring evenly, gradually increase the temperature to 85±5°C, and keep it at this temperature React for 4±1 hours, then cool down;

[0056] (3) Cool down to below 40°C, add the prescribed amount of water-removing agent, stir evenly, filter, after the foam is eliminated, pack, and obtain an environmentally friendly formwork paint.

Embodiment 9-17

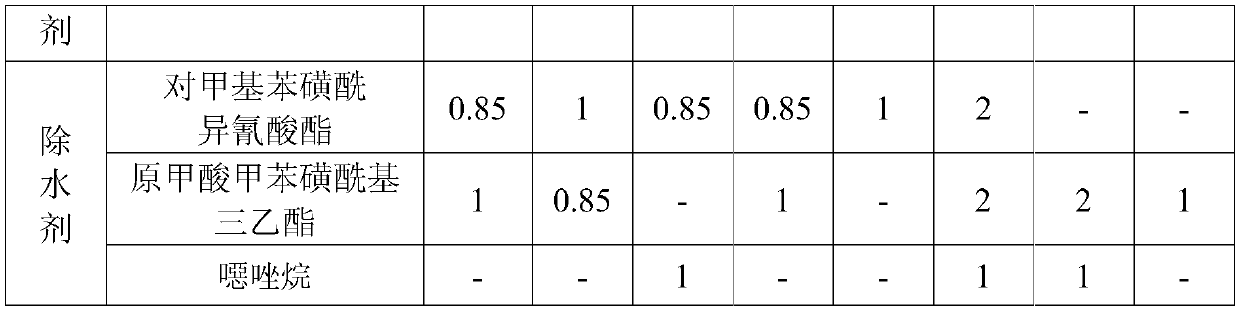

[0059] Example 9-17 Environment-friendly stencil paint A1~A8 and the performance test of the stencil paint of Comparative Example 1

[0060] The solid content, heat storage stability and closed flash point of the environment-friendly stencil paint A1-A8 and the stencil paint A9 of Comparative Example 1 were tested, and the results are shown in Table 2.

[0061] Table 2 Performance comparison of environment-friendly stencil paint A1-A8 and stencil paint A9 of Comparative Example 1

[0062]

[0063] From the data in Table 2, it can be seen that the environmentally friendly stencil paints A1-A8 prepared in Examples 1-8 were stored at 50°C for 30 days and passed the thermal stability test. According to industry experience, it is equivalent to storing at room temperature for more than 1 year. The stencil paint of Comparative Example 1 can only be stored for 15 days. It can be seen that the environment-friendly stencil paint of the present invention has excellent thermal stabil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com