An integrated method of underground gangue transportation, crushing and filling in mines

A gangue and mine technology, which is applied in the integrated field of mine gangue transportation-crushing-filling, can solve the problems of frequent filling and filling, frequent movement of equipment, and complicated steps, so as to reduce the frequency of equipment movement and solve complex disassembly problems. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

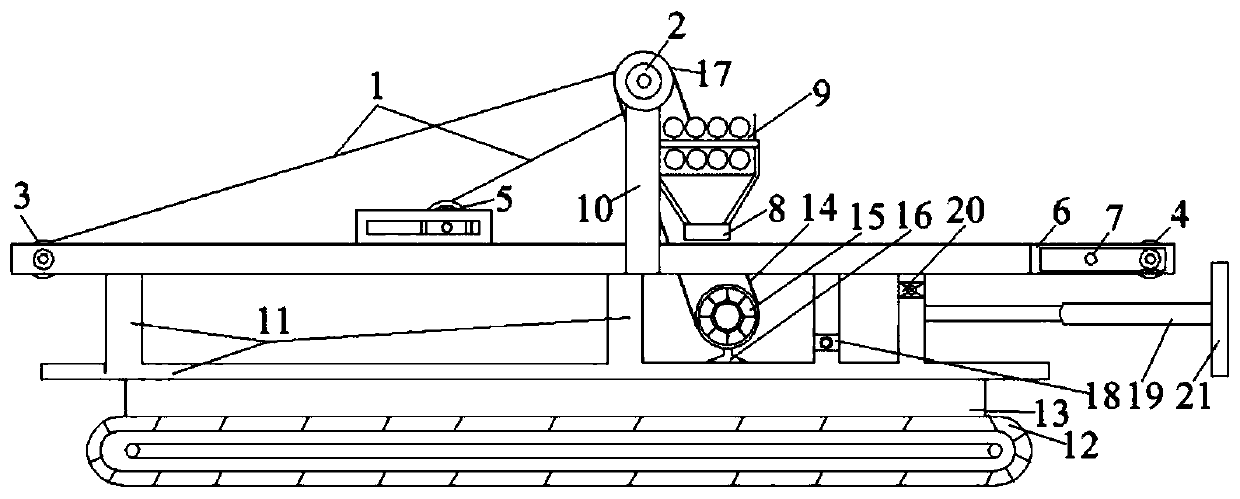

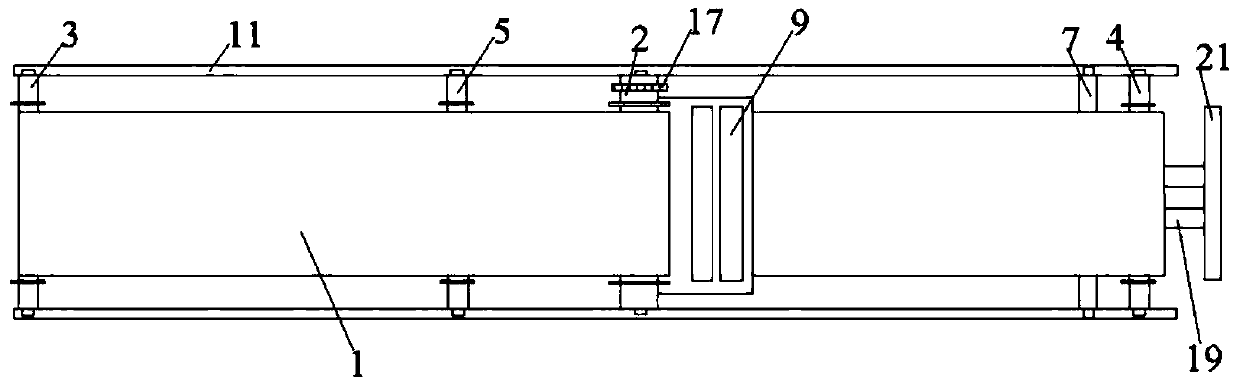

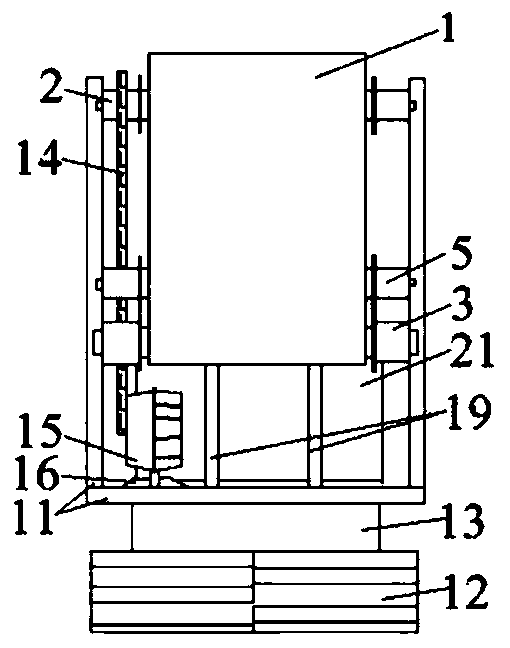

[0019] like Figure 1~3 As shown, the present invention provides an integrated method of gangue transportation-crushing-filling in mines, which mainly includes: adjusting the fastening nut of the fixed rod of the telescopic frame and the nut of the bearing seat of the rear moving roller according to the site conditions to realize the overall forward and backward movement of the rubber belt , turn on the speed control switch to start the motor, place the large pieces of gangue to be crushed on the initial belt and drop them into the crusher. After the position, open the hydraulic push column to push the tamping plate forward to tamp the gangue pile. The forward and backward movement of the front moving drum and the rear moving drum interacts with the overall movement of the base and steel frame driven by the crawler to complete the overall filling of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com