DEH control system and method under steam turbine distributed control system (DCS)

A technology of DCS system and control method, which is applied in the direction of engine control, mechanical equipment, engine components, etc., and can solve the problems of equipment complexity, operation parameter diversity, optimal operation mode, influence on the normal operation of the steam turbine unit, and influence on the service life of the steam turbine, etc. To achieve the effect of improving power supply quality, improving power quality and operating economy, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

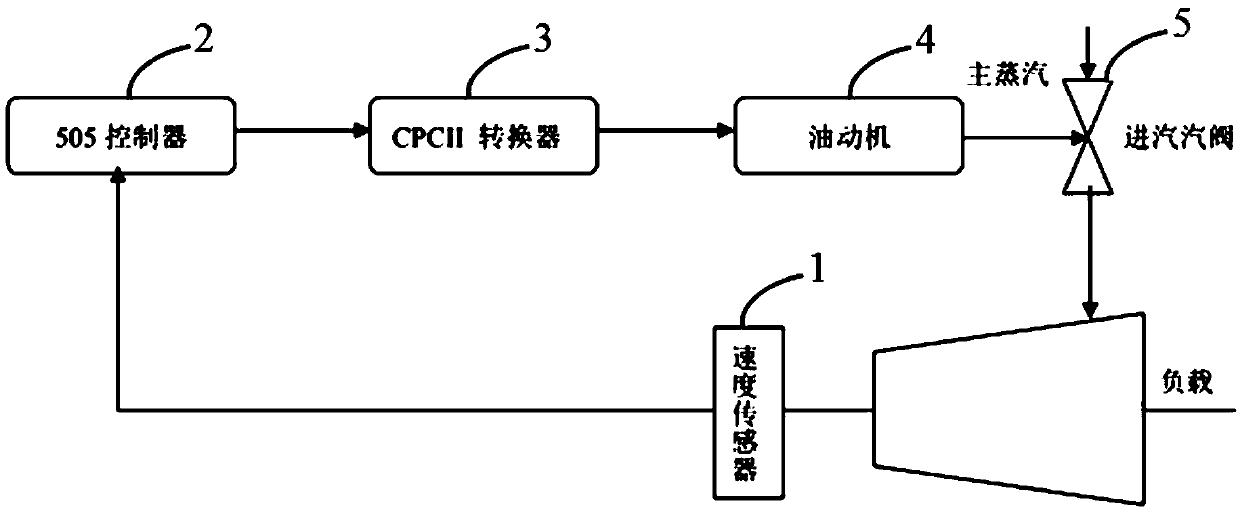

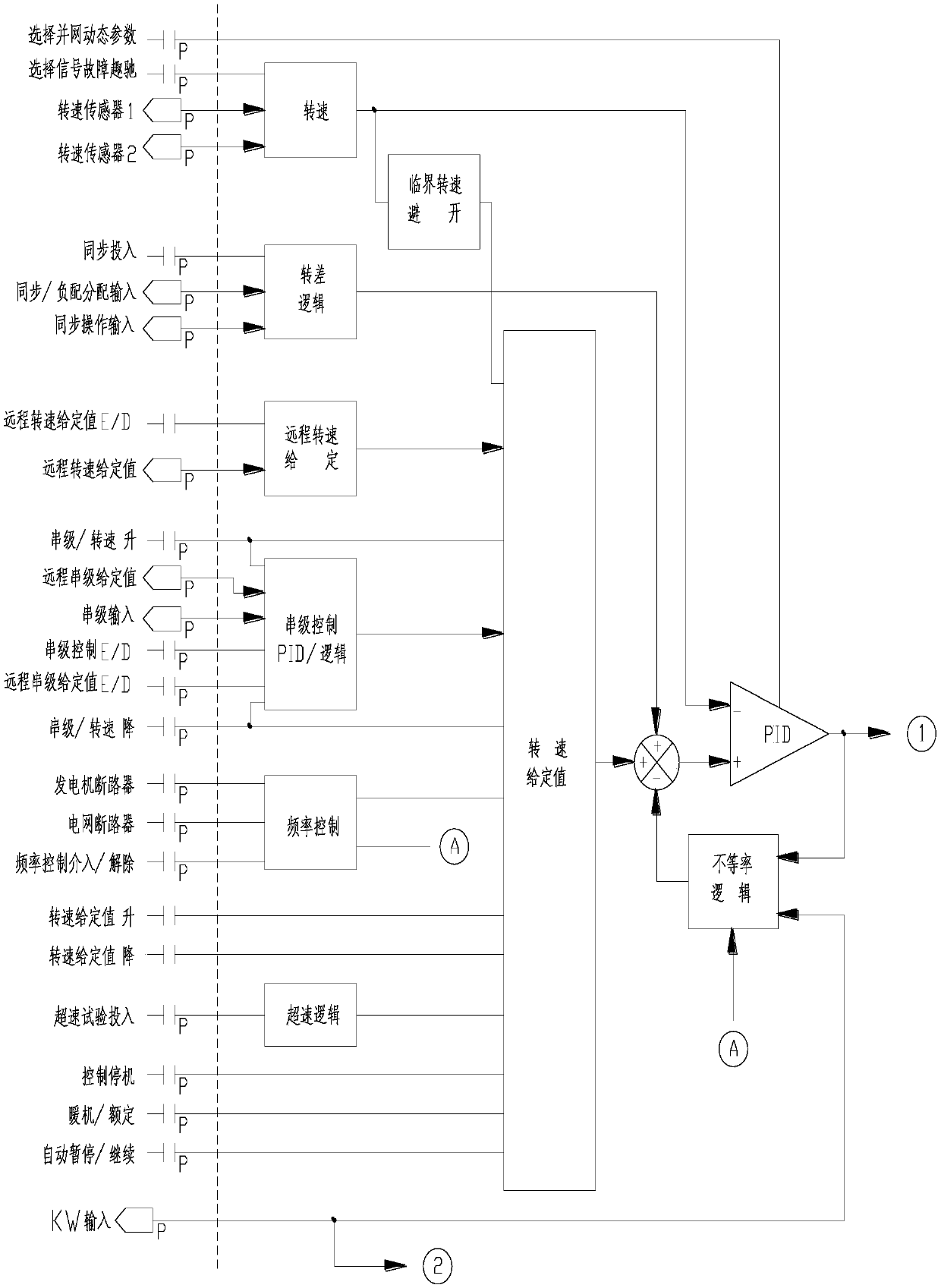

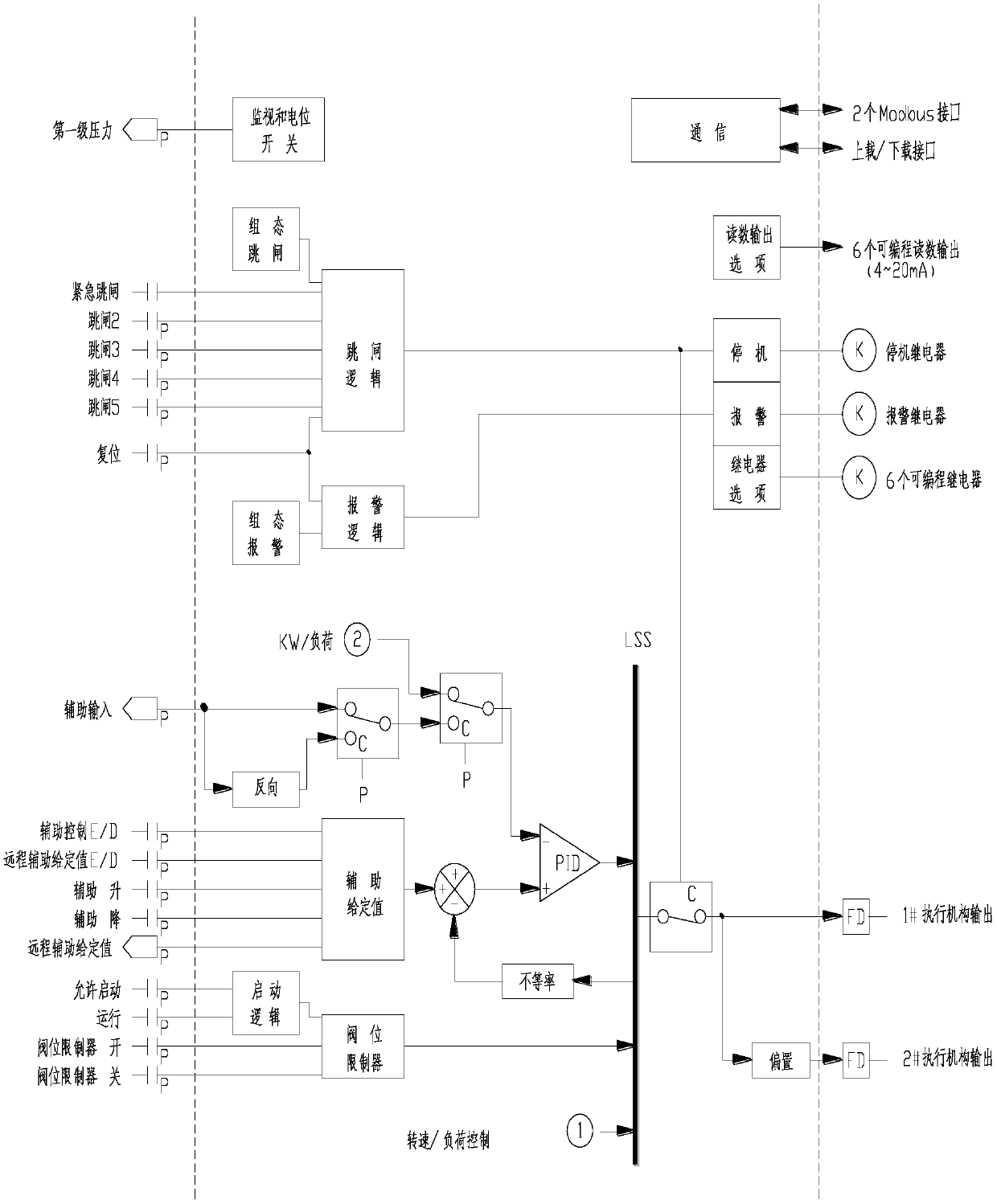

[0072] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0073] The DEH control method under the steam turbine DCS system provided by the embodiment of the present invention, the DEH control method under the steam turbine DCS system includes:

[0074] Change the force distance by increasing / decreasing the air intake volume or air intake parameters of the gas turbine, so that the force distance and the change of the resistance torque are balanced and adapted to the change of the external load, and the unit speed is kept basically unchanged;

[0075] Control the steam flow rate D of the steam turbine torque formula, and change the steam turbine torque M T , so that the steam turbine torque M T Always follow the generator electromagnetic torque M G Change with the change of the speed, maintain the speed n within the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com